- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jindelong

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Customization

-

Weight:

-

600000 kg

-

Product name:

-

JDL-5000 Kraft Paper Making Machine

-

Raw material:

-

Waste Carton Paper

-

Finished Products:

-

Big Roll Corrugated Paper

-

Advantage:

-

High Efficiency Automatic Working

-

Paper width:

-

5000mm

-

Design Speed:

-

400 m/min

-

Working Speed:

-

300-350 m/min

-

Capacity:

-

200-300 t/d

-

GSM:

-

100-300g/㎡

-

After-sales service:

-

Professional Technical Guidance

Quick Details

-

Type:

-

Paper Machine

-

Production Capacity:

-

400 m/min

-

Max. workable width:

-

5000mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jindelong

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Customization

-

Weight:

-

600000 kg

-

Product name:

-

JDL-5000 Kraft Paper Making Machine

-

Raw material:

-

Waste Carton Paper

-

Finished Products:

-

Big Roll Corrugated Paper

-

Advantage:

-

High Efficiency Automatic Working

-

Paper width:

-

5000mm

-

Design Speed:

-

400 m/min

-

Working Speed:

-

300-350 m/min

-

Capacity:

-

200-300 t/d

-

GSM:

-

100-300g/㎡

-

After-sales service:

-

Professional Technical Guidance

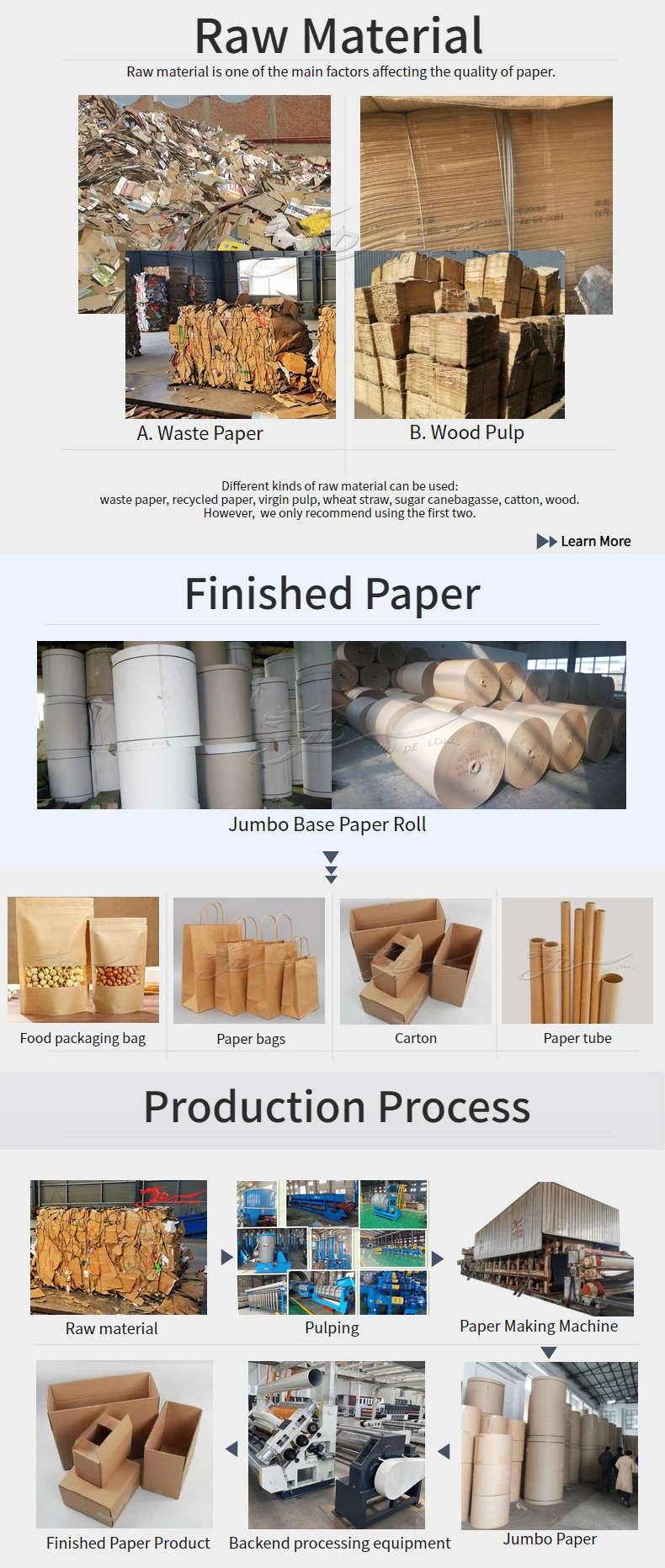

Raw Material & Finished Paper

Detailed Description

Product Parameters

|

Model

|

JDL-1575

|

JDL-1880

|

JDL-2400

|

JDL-2880

|

JDL-3200

|

JDL-5000

|

||||||

|

Paper width (mm)

|

1575

|

1880

|

2400

|

2880

|

3200

|

5000

|

||||||

|

Capacity (t/d)

|

5-10

|

15-40

|

30-40

|

45-60

|

50-80

|

200-300

|

||||||

|

Design speed (m/min)

|

100

|

120

|

120

|

150

|

200

|

400

|

||||||

|

Working speed (m/min)

|

50-80

|

60-100

|

60-80

|

80-120

|

150-180

|

300-350

|

||||||

|

Raw material

|

Waste paper, wood pulp

|

|

|

|

|

|

||||||

|

Paper weight (gsm)

|

80-250 g

|

|

|

|

|

|

||||||

|

Customized on demand

|

|

|

|

|

|

|

||||||

|

No.

|

Name

|

Function

|

|

1

|

Forming wire

|

Extract the pulp fiber to felt

|

|

2

|

Alloy dryer cylinder

|

Dry the wet paper

|

|

3

|

Double-layer dryer hood

|

Cover dryer and collect the hot&moist air diffused by dryer

|

|

4

|

Axial-flow ventilator

|

Ventilate and pull out the hot&moist air in the exhaust hood

|

|

5

|

Roots vacuum pump

|

Provide vacuum force for suction box

|

|

6

|

Air compressor

|

Provide compressed air for pneumatic devices

|

|

7

|

Frequency conversion controlling cabinet

|

Control the speed of the machine

|

|

8

|

Vacuum suction box

|

Absorb water contained in the wet paper

|

|

9

|

High concentration hydrapulper

|

Break the waste paper into pulp

|

|

10

|

High frequency vibrating screen

|

Separate and remove large impurity in the pulp

|

|

11

|

Impeller

|

Stir pulp and keep pulp well-mixed with water

|

|

12

|

Pressure screen

|

Getting ride of impurities

|

|

13

|

Bleacher

|

Bleach and whiten pulp

|

|

14

|

Double disc refiner

|

Grind, refine and fibrillation

|

|

15

|

Low concentration sand remover

|

Remove sand and impurities

|

|

16

|

Pulp pump

|

Pulp transportation

|

|

17

|

Electrical operation cabinet

|

Control machine operation

|

|

18

|

Boiler

|

Provide steam for the drying section

|

Recommend Products

Packing & Installation

Customer Photos

Service

Contact Us

Hot Searches