Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1500 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FOSITA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10m

-

Power (kW):

-

30

-

Weight:

-

1500kg

-

Name:

-

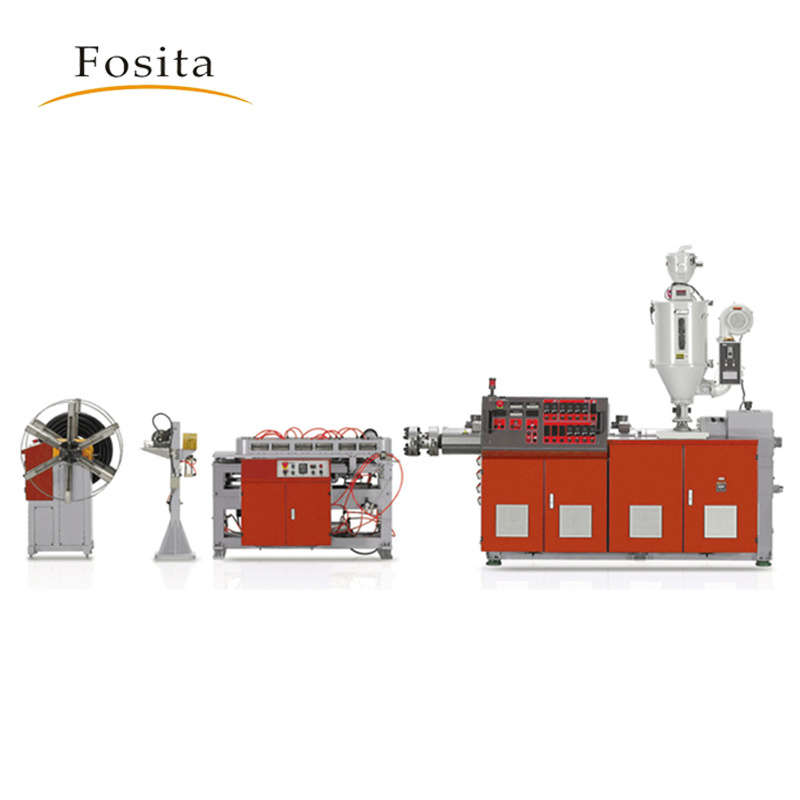

Corrugated Pipe Production Line Making Machine

-

application:

-

shisha,electrical

-

Pipe Diameter:

-

8-50mm

-

Speed:

-

8-20m/min

-

Type:

-

single wall corrugated pipe

-

Automatic Grade:

-

Automatic

-

Power(W):

-

37kw

-

Certification:

-

CE ISO

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw diameter (mm):

-

45 mm

-

Screw Speed (rpm):

-

1500 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FOSITA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10m

-

Power (kW):

-

30

-

Weight:

-

1500kg

-

Name:

-

Corrugated Pipe Production Line Making Machine

-

application:

-

shisha,electrical

-

Pipe Diameter:

-

8-50mm

-

Speed:

-

8-20m/min

-

Type:

-

single wall corrugated pipe

-

Automatic Grade:

-

Automatic

-

Power(W):

-

37kw

-

Certification:

-

CE ISO

Product Application

The line shall be used to produce small diameterr single wall corrugated pipe in PE/PVC and PP raw material.Molding corrugated pipe with smooth inside and outside surface,and even ripple at one time by corresponding die.Used as electricity pipe,washing machine drain pipe,dust collector pipe and ventiduct,etc.

Characteristic

1.High cost performance and long life

2.High stability and precision performance

3.High automation degree

4.High production efficiency

5.Good after-sales service

The advantages of plastic corrugated pipes:

1. With both rigid and flexible: has sufficient mechanical properties, at the same time has excellent flexibility.

2. Compared with the plate pipe, corrugated pipe has lighter weight, save material, lower energy consumption, cheaper;

3.Corrugated pipes with smooth inner wall can reduce the flow resistance of liquid in the pipe, improve the transmission capacity;

4. Good performance in resistance to chemical corrosion, can resist the effect of alkali in the soil.

5. Pipe with corrugation form can increase the load resistance of the pipe to the soil, at the same time, do not affect its flexibility,so that it can be laid on the uneven ground continuously.

6. Easily to connect and good in tightness . Easily handing, easily install, reduce the labor intensity, reduce working period.

7. Wide using temperature range, inflaming retarding, self-extinguish, safety in use.

8. safe insulation, is an ideal material for the electric wire conduit.

65/30 single screw extruder

Screw diameter: 65mm

L/D Ratio: 30:1

Screw&barrel material: 38CrMoAlA

Motor: 37kw

Barrel heating method:Cast-alumium heating, with stainless steel protection

Output:120-180kg/h

Temperature Control: Ormon

Contactor: Dexili

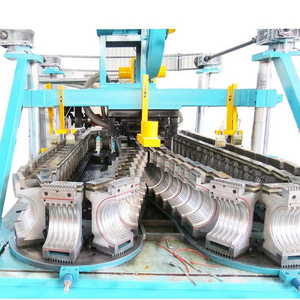

Corrugated pipe forming machine

Motor: 2.2kw

Frequency inverter: Delta

Production speed:8m/min

Quantity of shaping mould:60 pairs per set

Cooling method:Air cooling

Winder

Inner diameter of coil(mm):can be made as your request

Outside diamter of coil(mm):can be made as your request

Working method: Pneumatic