- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Roof,Wall,Underground,Bridge

-

Design Style:

-

Modern

-

Place of Origin:

-

China

-

Brand Name:

-

RG JIAYE

-

Model Number:

-

RGM-MB-APP

-

Type:

-

Waterproof Membrane

-

Product Name:

-

APP bitumen waterproof membrane

-

Thickness:

-

2.0mm-4.5mm

-

Width:

-

1000mm

-

Length:

-

10m/roll

-

Usage:

-

waterproofing in building

-

Color:

-

Black

-

Material:

-

APP Modified Asphalt

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

total solution for projects, Others

-

Application:

-

Roof,Wall,Underground,Bridge

-

Design Style:

-

Modern

-

Place of Origin:

-

China

-

Brand Name:

-

RG JIAYE

-

Model Number:

-

RGM-MB-APP

-

Type:

-

Waterproof Membrane

-

Product Name:

-

APP bitumen waterproof membrane

-

Thickness:

-

2.0mm-4.5mm

-

Width:

-

1000mm

-

Length:

-

10m/roll

-

Usage:

-

waterproofing in building

-

Color:

-

Black

-

Material:

-

APP Modified Asphalt

3mm 4mm APP Modified bitumen waterproof membrane for roofing

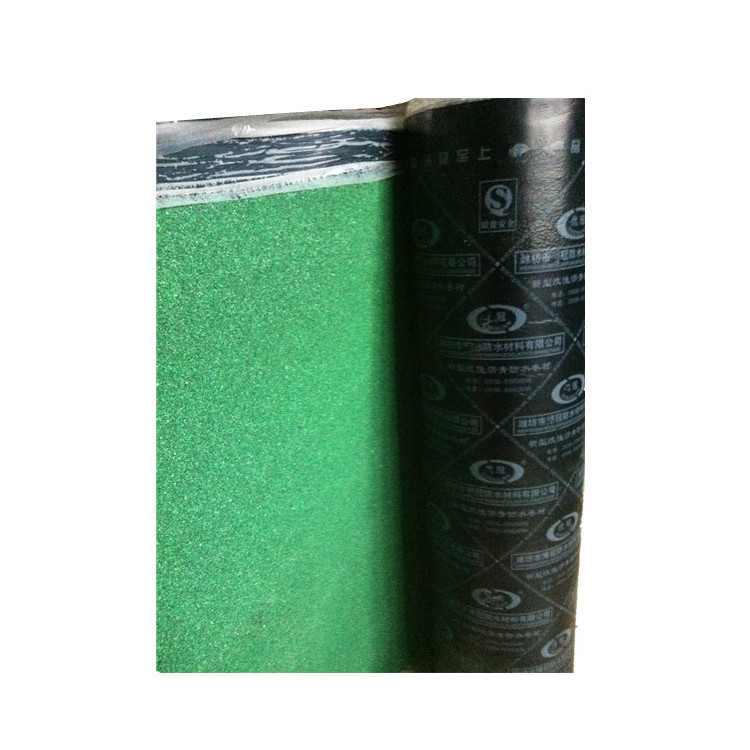

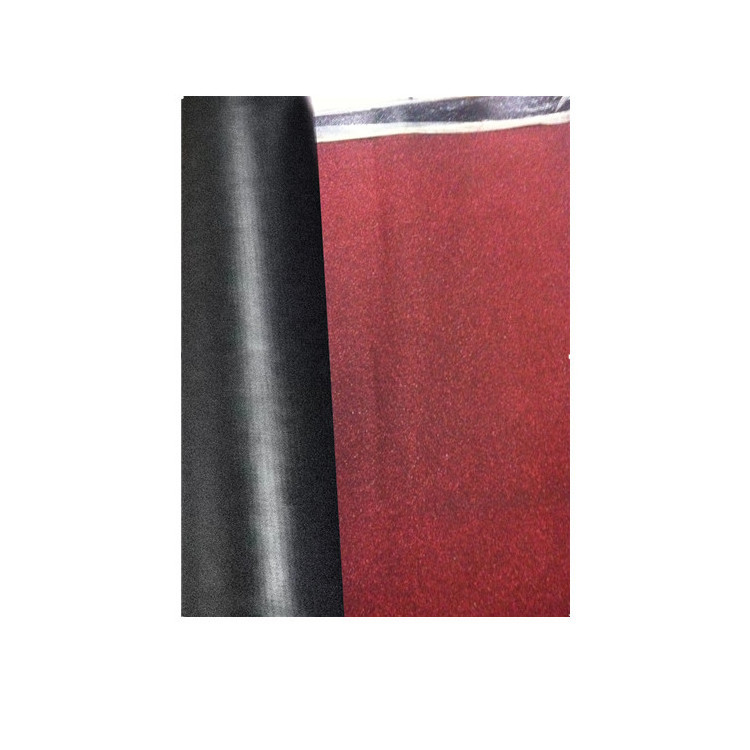

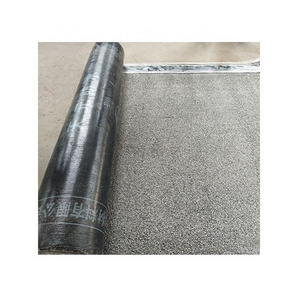

RGM-MB02 APP (Atactic Polypropylene) Modified Bitumen Membrane is made of APP or APAO, APO modified asphalt as dip - coat material, good polyester felt and glass fiber felt as base, and the surface covered with fine sand, mineral granule , PE film . It is a plastomer-modified bitumen waterproofing membrane made of advanced technology.

| Surface Coating Material | F ine sand, mineral granule, PE film, aluminum film, and other insulation materials. |

| Color | White\black\grey\blue\green, or customized |

| Thickness | 3.0mm\4.0mm or customized |

| Width | 1m |

| Length | 10m, 15m or customized |

| Reinforcement | Polyester or fiberglass |

|

Item |

I |

II

|

||||

|

PY |

G |

PY |

G |

PYG |

||

|

Soluble matter content (g/m 2 ) ≥ |

3.0mm |

2100 |

-- |

|||

|

4.0mm |

2900 |

-- |

||||

|

5.0mm |

3500 |

|||||

|

Test phenomenon |

-- |

Non-ignitable |

-- |

Non-ignitable |

-- |

|

|

Heat resistance |

℃ |

110 |

130 |

|||

|

≤mm |

2 |

|||||

|

Test phenomenon |

No flowing, no dripping |

|||||

|

Low temperature flexibility ℃ |

-7 |

-15 |

||||

|

No crack |

||||||

|

Watertightness, 30min/MPa |

0.3MPa |

0.2MPa |

0.3MPa |

|||

|

|

Maximum peak (N/50mm)≥ |

500 |

350 |

800 |

500 |

900 |

|

|

Second peak (N/50mm)≥ |

-- |

-- |

-- |

-- |

800 |

|

|

Test phenomenon |

No crack or separating |

||||

|

Elongation |

Maximum peak rate %≥ |

25 |

-- |

40 |

-- |

-- |

|

Second peak rate %≥ |

-- |

-- |

15 |

|||

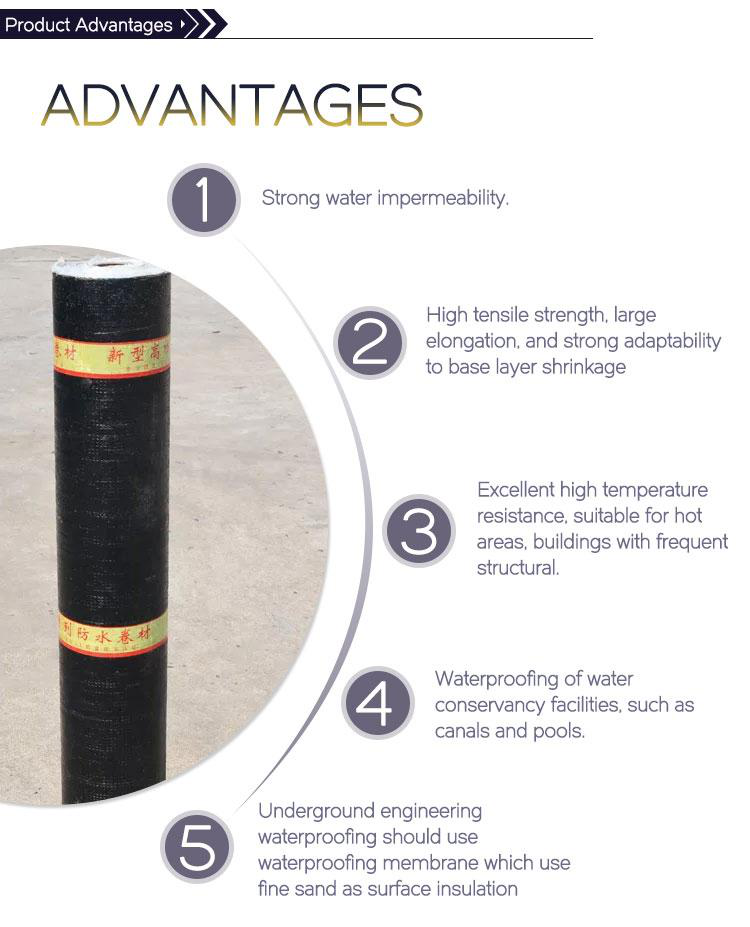

1. Waterproofing of various industrial and civil building roofing projects.

2. Waterproof, moisture-proof, and structural structures such as indoor swimming pools and fire fighting pools for underground projects in industrial and civil buildings.

3. Waterproofing of municipal projects such as subways, tunnels, concrete pavement decks, sewage treatment sites, and landfills.

4. Waterproofing of water conservancy facilities, such as canals and pools.

5. Underground engineering waterproofing should use waterproofing membrane which use fine sand as surface insulation material all.

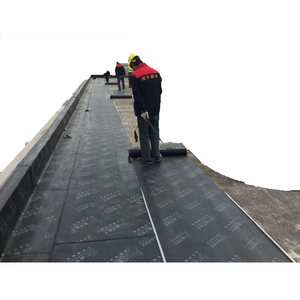

Construction:

1. Base treatment: The base layer should be solid, smooth and clean. The protruded corners and recessed corners should be treated with circular arc, and the base treatment primer should be evenly applied. It should not be exposed to the bottom. The membrane can be laid after the surface is dry.

2. Attachment of waterproof layer in detail: The protruded corners and recessed corners, tube root, sulcus, deformation joint and other parts should be treated as additional layer, and the pre-cut size and shape should be laid on the base layer.

3. Large-face construction: the membrane is opened to release the stress, and it is pre-laid according to the position of the plane elastic line. After pre-laying, it is rolled from the two ends to the middle, and the web is rolled from the middle to the both ends. The end of the waterproof layer should be fixed with a metal bead and sealed with a sealant.

4. Protection of the isolation layer: The outer surface of the waterproof layer shall be provided with a protective layer according to the relevant specifications or design requirements. When membrane with its surface covered with shale sheet or the mineral granule is used as the exposed waterproof layer, no protective layer is provided.

1. When storing and transporting, different types and specifications of the membrane should be stored separately and should not be mixed. Avoid sun and rain, pay attention to ventilation. The storage temperature should not exceed 50 ° C, the vertical storage can only be a single layer, and the vertical placement should not exceed two layers during transportation.

2. Prevent tilting or horizontal pressure during transportation, and cover the cloth if necessary.

3. Under normal storage and transportation conditions, the storage period is one year from the date of production.