- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

250kwh

-

Dimension(L*W*H):

-

60mX10mX6m

-

Weight:

-

3000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

color:

-

optional

-

output paper:

-

kraft liner paper

-

capacity:

-

205tons

-

raw material:

-

OCC, white paper edge

-

output paper weight:

-

115-350g/m2

-

Net paper width:

-

4000mm

-

Wire width:

-

4400mm

-

Working speed:

-

100-250m/min

-

automatic:

-

yes

Quick Details

-

Production Capacity:

-

120 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen

-

Voltage:

-

380V

-

Power:

-

250kwh

-

Dimension(L*W*H):

-

60mX10mX6m

-

Weight:

-

3000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

color:

-

optional

-

output paper:

-

kraft liner paper

-

capacity:

-

205tons

-

raw material:

-

OCC, white paper edge

-

output paper weight:

-

115-350g/m2

-

Net paper width:

-

4000mm

-

Wire width:

-

4400mm

-

Working speed:

-

100-250m/min

-

automatic:

-

yes

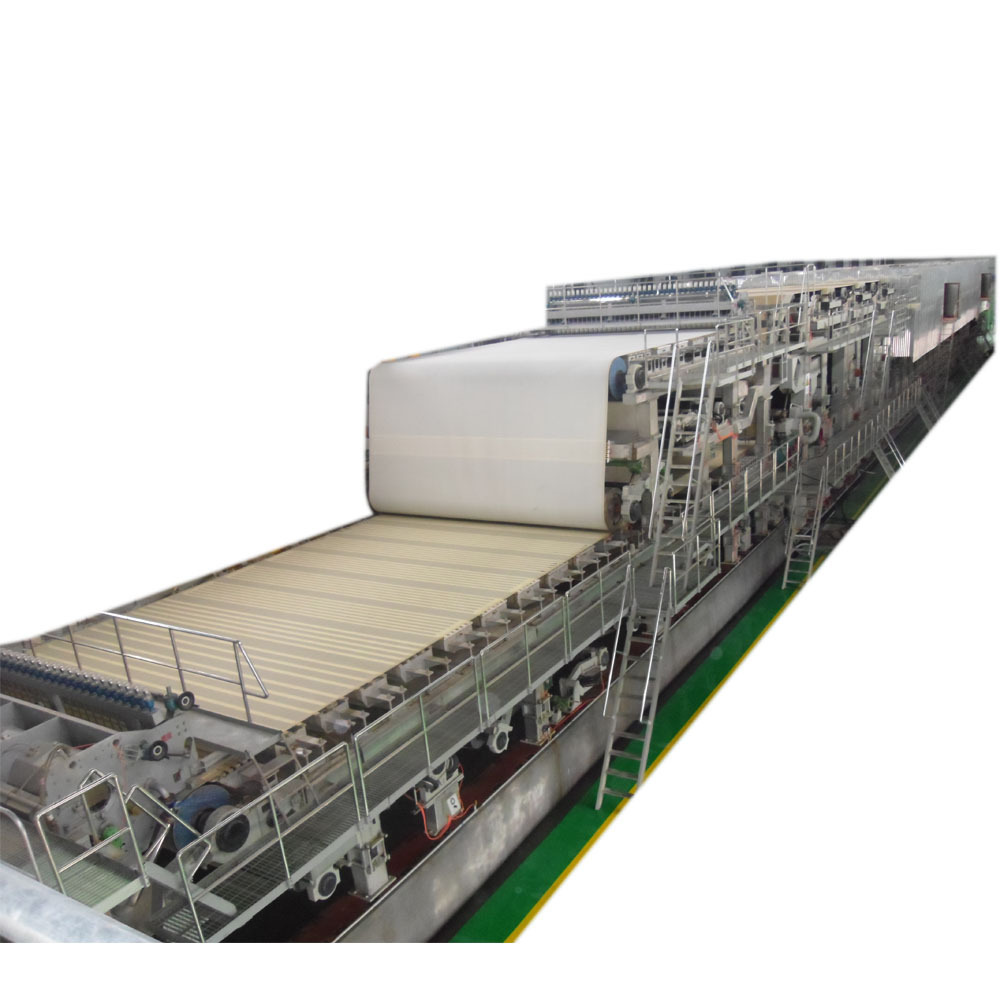

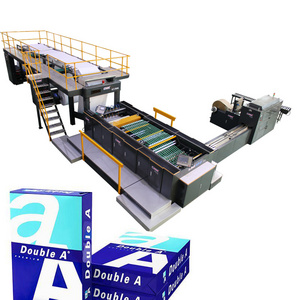

High Speed 3800mm 205tons Kraft Liner Paper Test liner Paper Duplex Kraft Paper And Fluting Paper Production Line

1. Raw material: OCC, white paper edge

2. Output paper: kraft liner paper

3. Output paper weight: 115-350g/m 2

4. Net paper width:4000mm

5. Wire width: 4400mm

6. Capacity: 205T/D

7. Working speed: 100-250m/min

8. Designing speed: 300m/min

9. Rail gauge: 5000mm

10. Drive way: A/C inverter speed control, sectional drive.

1. Wire part

Three wire designing, bottom wire table length 16m, top double-wire table length 8m, frame welded by #45 steel plate, covered by stainless steel board. With 3 sets closed flow box, made of stainless steel, with double evener rolls. Wire changing type: by cantilever bean.

2. Press part

2 sets of press rolls in large diameter.

4 pcs Blind press roll Φ1350mm×4400mm×5000mm, rubber shore hardness 96℃±2, with pneumatic pressure device. Adopting frame-type machine structure.

3. Dryer part

37 sets of Φ 1500mm×4400mm×5000mm alloy dryer cylinder with 37 pcs of doctor blade. Dryer cylinders are arrayed in the order of 25 + sizing machine + 12.

4. Sizing part

1 set of inclined-type sizing machine, top roll Φ 1000mm×4400mm×5000mm imitation stone roll, bottom roll Φ 1005mm×4400mm×5000mm rubber roll, rubber shore hardness 96℃±2..

5. Calendering part

Hard calendering machine with chilled rolls.

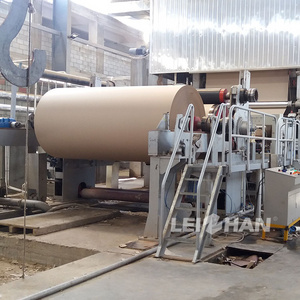

6. Winding part

1 set of horizontal pneumatic winding machine with winding cylinder Φ 1100mm×4400mm×5000mm.

7. Rewinding part:

1 set of 3800mm Frame structure rewinding machine.