- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jiangsu Sifang

-

Dimension(L*W*H):

-

Depends

-

Weight:

-

Depends

-

Function:

-

Multifunctional

-

Product name:

-

SFG

-

Applicable Fuel:

-

Coal-fired

-

Advantages:

-

Top 1 A-Class Boiler

-

Feature:

-

High Effenciency

-

Quality:

-

High-quality

-

Marketing Type:

-

Hot Product

Quick Details

-

Core Components:

-

drum

-

Steam Production:

-

Max. 280t/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jiangsu Sifang

-

Dimension(L*W*H):

-

Depends

-

Weight:

-

Depends

-

Function:

-

Multifunctional

-

Product name:

-

SFG

-

Applicable Fuel:

-

Coal-fired

-

Advantages:

-

Top 1 A-Class Boiler

-

Feature:

-

High Effenciency

-

Quality:

-

High-quality

-

Marketing Type:

-

Hot Product

Product Overview

S

FG Oil Gas Fired

Boiler

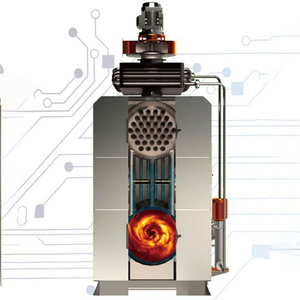

Based on sophisticated oil-gas fired boilers production experience, our SFG oil-gas fired boilers are used for ecological power generation through years of cooperation with famous domestic scientific research institutions and universities.

The structure of SFG oil-gas fired boilers are mainly π-type.

Our Oil-Gas Fired Boilers:

1.

Available fuel

: gas, coke oven gas, blast-furnace gas, converter gas, manufactured gas, chemical fuel gas, light oil, heavy oil.

2.

Product thermal capacity

: 35t/h-280t/h

3.

Working pressure

: low pressure, medium pressure, intermediate pressure, high pressure steam

4.

Steam temperature

: Various types of saturated temperature parameters, low temperature superheater, medium temperature and medium pressure, high pressure high temperature

5.

Structure feature

: π-type oil-gas fired boiler

|

Product name

|

SFG (π-type) Oil Gas Fired Boiler

|

|

Application

|

Hotels, hospitals, medicine industry, restaurants, food industry, papermaking, heating, schools, mining, farms, clothing,manufacturing, machinery maintenance

|

|

Type

|

Natural Circulation

|

|

Structure

|

Fire Tube

|

|

Applicable Fuel

|

Coal-fired

|

Technical Advantages

Unique Structural Design

1.

The boiler adopts light furnace wall and pipe-laying furnace wall structure, which can be freely expanded in all directions, with light weight and good heat preservation performance.

2.

The boiler is easy to arrange and suitable for various capacities and various fuels.

3.

The auxiliary heating surfaces such as energy saver and air preheater are supplied in a modular way to reduce the installation workload on site.

4.

Membrane wall and serpentine tube adopt standardized design to reduce the delivery cycle.

Energy Conservation and Environmental Protection

1.

The boiler adopts the idea of furnace design to reduce the furnace volume heat release rate, and with the professional burner, the NOx emission is as low as less than 30mg/Nm³.

2.

According to the characteristics of the fuel, the feed water preheater, air preheater and other heating surfaces are reasonably arranged to ensure the highest energy efficiency.

More Products

Hot Searches