- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong

-

Model Number:

-

YG -220

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

11000*4400*1800 mm

-

Weight:

-

9000 KG

-

Product name:

-

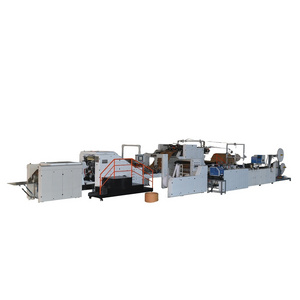

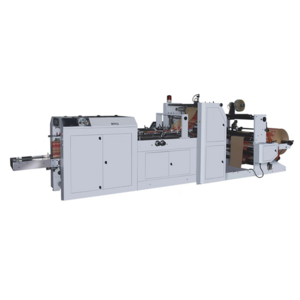

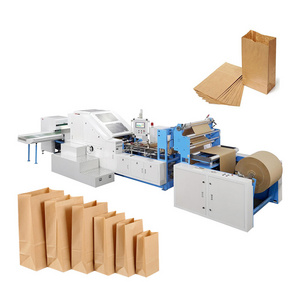

Fully Automatic Bag Making Machine

-

Application:

-

Food Packaging

-

Function:

-

Paper Bag Producing

-

Speed:

-

30-200pcs/min

-

Processing Type:

-

Heat Sealing Hot Cutting

-

Paper thickness:

-

80-150g/m2

-

Paper bag bottom width:

-

60-180mm

-

Paper Cutting length:

-

270-530 mm

-

Roll paper diameter:

-

1300 mm

-

Paper roll width:

-

650-1290mm

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong

-

Model Number:

-

YG -220

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

11000*4400*1800 mm

-

Weight:

-

9000 KG

-

Product name:

-

Fully Automatic Bag Making Machine

-

Application:

-

Food Packaging

-

Function:

-

Paper Bag Producing

-

Speed:

-

30-200pcs/min

-

Processing Type:

-

Heat Sealing Hot Cutting

-

Paper thickness:

-

80-150g/m2

-

Paper bag bottom width:

-

60-180mm

-

Paper Cutting length:

-

270-530 mm

-

Roll paper diameter:

-

1300 mm

-

Paper roll width:

-

650-1290mm

Product Description

F

ull Automatic and Semi-automatic Paper Bag Making Machine

This machine is used for roll primary color paper or printing roll paper such as Kraft paper. Paper rolls such as food paper are completed by this machine at one time. Automatic center gluing, raw material into tube, cut to length, bottom indentation, bottom folding. Glue on the bottom and shape the bottom of the bag. Finished bag finishing is completed at one time. This machine is more convenient to operate, more efficient and more stable. It is an environmentally friendly paper bag machine equipment that produces various paper bags, snack food bags, bread bags, dried fruit bags, etc.

Specification

Product Feature

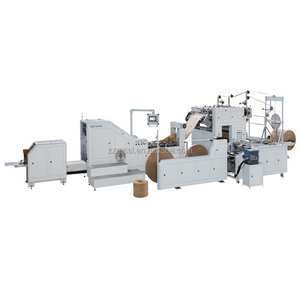

Kraft paper bag making machine

Semi-automatic & Full-automatic paper bag machines, which can quickly produce paper handle with twisted rope, which can be attached onto the paper bag without handles in further production and make it into paper handbags. This machine takes two narrow paper rolls and one paper rope as raw material, sticks scraps of paper and paper rope together, which will be cut off gradually to form paper handles. In addition, the machine also has automatic counting and gluing functions, which can greatly improve the efficiency of subsequent processing operations of users.

1. The machine is easy to operate and can produce paper handles with high speed usually reach 170 pairs per minute.

2. We design and offer the optional auto-production line, which can automatic gluing replace the human gluing procedure so that help to reduce lots of labor cost. It is strongly advice the paper bag producing factory use the auto-produce line that also support customize.

3. The unit paper bag can lift the heavy things of 15 kg at most, when the tension of raw materials reaches a certain level. 4. This machine adopts melt-glue machine with service points in many countries, can provide customers with the fastest service.

1. The machine is easy to operate and can produce paper handles with high speed usually reach 170 pairs per minute.

2. We design and offer the optional auto-production line, which can automatic gluing replace the human gluing procedure so that help to reduce lots of labor cost. It is strongly advice the paper bag producing factory use the auto-produce line that also support customize.

3. The unit paper bag can lift the heavy things of 15 kg at most, when the tension of raw materials reaches a certain level. 4. This machine adopts melt-glue machine with service points in many countries, can provide customers with the fastest service.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Factory

Hot Searches