- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

As customer request.

-

Dimension(L*W*H):

-

22000X1500X2300M

-

Weight:

-

14000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

trade assurance fish feed pellet mill machinery

-

Application:

-

Fish

-

Raw material:

-

Wheat Bran

-

Usage:

-

Animal Poultry Livestock Pellet Making Machine

-

Color:

-

Clients' Requirement

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Motor:

-

Siemens Motor

-

Material:

-

Stainless Steel Frame Structure

-

Keywords:

-

floating fish food making extruder machine

Quick Details

-

Max. Capacity:

-

200KG/H

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sunward fish feed machinery

-

Voltage:

-

As customer request.

-

Dimension(L*W*H):

-

22000X1500X2300M

-

Weight:

-

14000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

trade assurance fish feed pellet mill machinery

-

Application:

-

Fish

-

Raw material:

-

Wheat Bran

-

Usage:

-

Animal Poultry Livestock Pellet Making Machine

-

Color:

-

Clients' Requirement

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Motor:

-

Siemens Motor

-

Material:

-

Stainless Steel Frame Structure

-

Keywords:

-

floating fish food making extruder machine

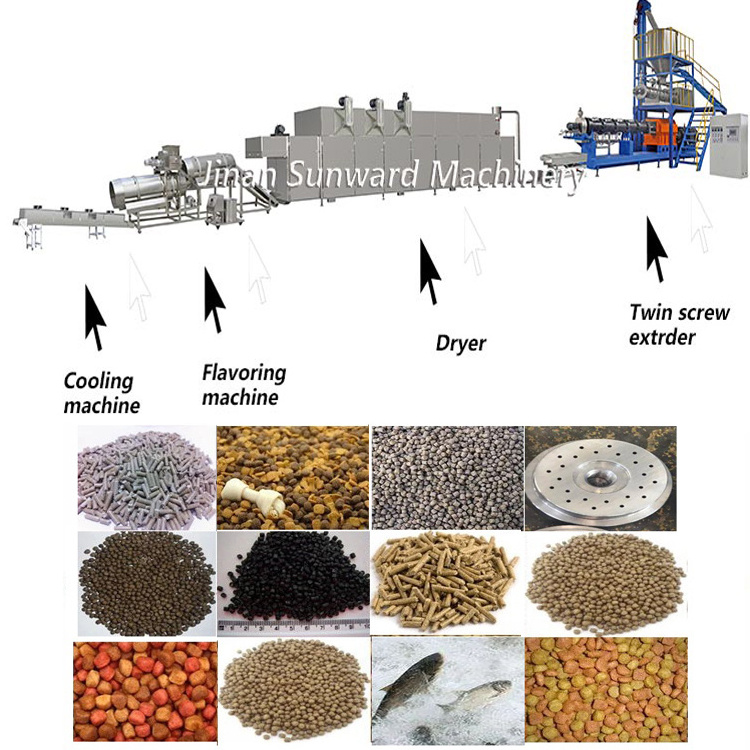

Automatic fish feed production line fish feed making machine with 1 ton per hour

1. Brief Introduction :

How is fish feed made by our fish feed pellet mill machinery ?

- High quality ingredients (fish meal, cereals, vegetable proteins …) are selected and ground according to the specific nutritional and pellets size requirements of the aquatic animals and various fish request.

- The particle quantity of fish feed raw material is a key factor for premium granulates production : therefore the grinding step is an important unit operation. The powder is then mixed with minor ingredients such as vitamins, mineral premixes… prior to the preconditioning ot to the fish extruder directly.

- Next, the heart of the process, extrusion cooking is done in three stages in the fish feed machine : preconditioning, extrusion cooking and die texturing/ shaping. Twin-screw extrusion-cooking uses its perfect mixing ability and parameters control such as shear, temperature, residence time to reach the highest physical and nutritional standards. Through direct steam injection, venting device and efficient barrel cooling, adjustable screw speed, screw configuration, shear and temperature conditions are perfectly controlled ; this leads to optimized functional and nutritional pellet properties such as the bulk density, calibration, cooking degree, best ratio proteins- lipids, etc

- Fish feed Pellets can then be oil coated and possible additives and are cooled down to complete the fish feed processing.

2. Capacity: 100-500kg/h

3. Voltage in China:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers'local voltage according to different countries.

4. Machines Materials:

All the machines are made by stainless steel .

5. Technical Parameter:

|

Model |

Installed power |

Consumption |

Output |

Dimension |

|

TSE65-P |

70kw |

40kw/h |

100-150kg/h |

22000*1200*2200mm |

|

TSE70-P |

90kw |

50kw/h |

200-240kg/h |

25000*1500*2200mm |

|

TSE85-P |

120kw |

100kw/h |

400-500kg/h |

30000*3500*4300mm |

|

TSE90-P |

135kw |

100kw/h |

800-1200kg/h |

30000*3500*4300mm |

|

TSE95-P |

150kw |

130kg/h |

2000-3000kg/h |

33000*3500*4300mm |

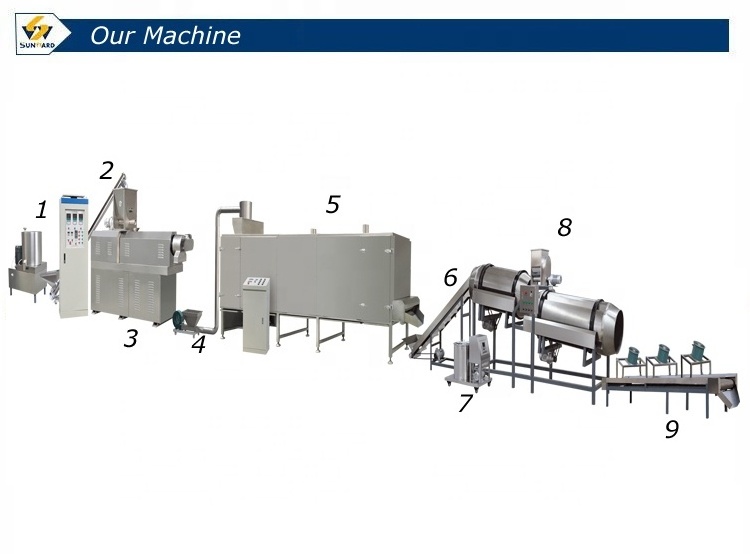

6. Flow chart:

Mixer---Screw Conveyor---Twin- screw extruder--- Air conveyor---Dryer ---Flavoring line---Cooling machine

Final product by our fish feed pellet mill machinery :

fish feed pellet , floating/sinking diameter from 0.2mm to 20mm

We have different models to produce different fish feed production from 0.2mm to 20mm.

Details of Multi- layer Dryer:

1. Introduction of our comapny

Our factory was founded in 2009 and our company is an industry and trade integrated enterprise. The company is committed to research and develop extrusion machinery and related ancillary equipment. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system, soy nuggets system, as well as pet food/fish food system. As the owning import and export right, machines are exported to more and more countries directly by ourselves. Which include Asia, America, Africa,Europe etc. Besides, our machines are welcome in the countries. So until now, there are not only direct customers, but also some long term cooperation agents.

2. About us

1. Testing Machine before package.

2. Packaging: inside is covered in plastic film, outside is wooden case.

3. Shipping: 15-35 working days after receiving deposit.

4. The pictures of our packaging logistics for your reference.

I. What's the pre-sale service of your company?

Related machines’s technical parameter will be supplied to customer.

1. According to customer’s factory size, factory layout can be provided in advance.

2. According to customer’s material cost, general formulation can be prepared well.

3. Special machine can be supplied as customer’s request.

4. Professional Advice about Market, machines, processing , materials, packing can be supplied.

5. Suggesting professional ship agent or helping book ship as customer request.

II. What's the after-sale service of your company?

1. Allocation chart as the buyer’s request will be supplied.

2. Operation manual will be supplied after shipment.

3. One year warrantee, life time maintenance with cost price.

4. Free easy broken spare parts will be sent with container .

5. First installation can be done by engineer.

6. Training workers in customer’s factory.

III. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer video.

IV. What's the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.

If you have any interests in our machines, please don't hesitate to contact us.