- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BUMTRESD

-

Material:

-

steel, nylon, stainless steel, PVC, UHMWPE, HDPE

-

Bearing Model:

-

6204,6205,6305,6306,6307,6308

-

Certificate:

-

ISO9001

-

Working Life:

-

≥30000 hours

-

Roller pipe:

-

Q235/carbon steel

-

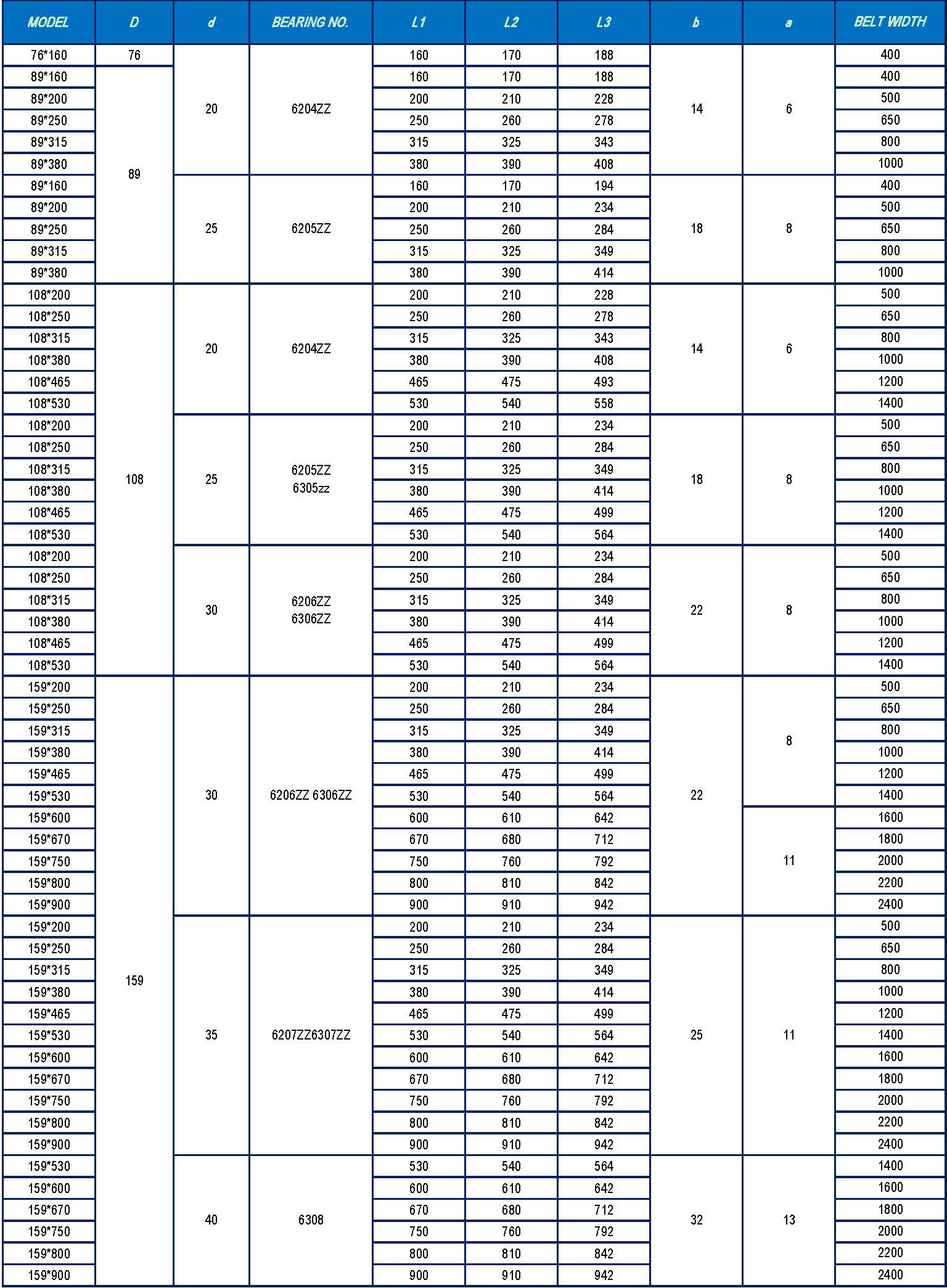

Diameter:

-

89/102/108/114/127/133/140/152/159/165/178/194/219

-

Length(mm):

-

190mm-3500mm(National and non-standard idlers)

-

Belt Width:

-

B450mm to B2200mm

-

Seal:

-

Multiple labyrinth seal, water proof, dust proof

-

Standard:

-

GB/CEMA/JIS/DIN/Australia

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

6

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

BUMTRESD

-

Material:

-

steel, nylon, stainless steel, PVC, UHMWPE, HDPE

-

Bearing Model:

-

6204,6205,6305,6306,6307,6308

-

Certificate:

-

ISO9001

-

Working Life:

-

≥30000 hours

-

Roller pipe:

-

Q235/carbon steel

-

Diameter:

-

89/102/108/114/127/133/140/152/159/165/178/194/219

-

Length(mm):

-

190mm-3500mm(National and non-standard idlers)

-

Belt Width:

-

B450mm to B2200mm

-

Seal:

-

Multiple labyrinth seal, water proof, dust proof

-

Standard:

-

GB/CEMA/JIS/DIN/Australia

A

| Material | steel, nylon, stainless steel, PVC, UHMWPE, HDPE |

| Bearing Model |

6204,6205,6305,6306,6307,6308 |

| Bearing Brand | HRB, LYC, ZWZ,SKF, NSK,C&U |

| Working Life | ≥30000 hours |

| Roller Pipe | Q235/carbon steel |

| Diameter | 89/102/108/114/127/133/140/152/159/165/178/194/219 |

| Length(mm) | 190mm-3500mm(National and non-standard idlers) |

| Belt Width | B450mm to B2200mm |

| Seal | Multiple labyrinth seal, water proof, dust proof |

| Standard | GB/CEMA/JIS/DIN/Australia |

| Special | can be customized according to customer or design for customer |

| Supply Ability | 1000pcs per day |

| Certificate | ISO9001,SGS |

| Application | recycling industry |

| power industry | |

| parcel transport industry | |

| petro industry | |

| coal mining industry | |

| cement concrete industry | |

| machining industry |

P roduct Overview

Conveyor roller is an important part of the belt conveyor. There are many types and large quantities of rollers, which can support the weight of the conveyor belt and the material been conveyed. The roller accounts for 35% of the total cost of a belt conveyor and generates more than 70% resistance, and plays a key role to extend the life of the conveyor belt, so the quality of the roller is particularly important.

Product Features At A Glance

1. Strong hardness and high wear resistance;

2. Good Sealing Performance - the carrying roller is fully sealed, and both ends are equipped with labyrinth seals, oil and grease will not leak, which can make the roller runs under a fully sealing state;

3. Long Service Life - the carrying roller can reduce belt wear, keep the belt run in its track, and extends the belt life;

4. Low Operating Cost - carrying rollers can reduce the overall cost of belt conveyors and reduce maintenance man-hours.

Product Configurations

Product Specifications

Successful Projects

Similar Products

F AQ

Q : What is the applciation scope for mining rollers?

A: *Ordinary Roller: grain, loading and transportation

*Trough Roller: coal, cement, electricity

*Trough Self-Aligning Roller: metallurgy. Mines, electric power, cement, chemicals, building materials, steel plants

*Drum Roller: metallurgy, chemical industry, coal, building materials

*Ground Roller: field mining

*Guide Roller: any conveyor system

*Hanging Roller: any belt conveyor

*Backstop Roller: metallurgy. mines, power, cement, chemicals, building materials, steel