Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

- Product Details

- {{item.text}}

Quick Details

-

Forming Time:

-

0.5s

-

Welding Mode:

-

Crosswise

-

Welding Diameter:

-

10-50cm

-

Dimensions:

-

2200*1100*1600mm

-

Use:

-

Seam Welding

-

Voltage:

-

380V

-

Weight (KG):

-

650 KG

-

Power (kW):

-

5.5

-

Power supply:

-

380V±10%

-

Rated input voltage:

-

40KVA

-

Duration of rated load:

-

40%

-

Wire feed speed:

-

6-12m/min

-

Wire diameter:

-

2.0-2.2mm

-

Minimum diameter of welding workpiece:

-

100mm

-

Maximum diameter of welding workpiece:

-

500mm

-

Material for welding workpieces:

-

Cold-rolled steel or tinplate

-

Thickness range:

-

0.5-1.0mm

-

Dimension:

-

2200*1100*1600

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOBO

-

Forming Time:

-

0.5s

-

Welding Mode:

-

Crosswise

-

Welding Diameter:

-

10-50cm

-

Dimensions:

-

2200*1100*1600mm

-

Use:

-

Seam Welding

-

Voltage:

-

380V

-

Weight (KG):

-

650 KG

-

Power (kW):

-

5.5

-

Power supply:

-

380V±10%

-

Rated input voltage:

-

40KVA

-

Duration of rated load:

-

40%

-

Wire feed speed:

-

6-12m/min

-

Wire diameter:

-

2.0-2.2mm

-

Minimum diameter of welding workpiece:

-

100mm

-

Maximum diameter of welding workpiece:

-

500mm

-

Material for welding workpieces:

-

Cold-rolled steel or tinplate

-

Thickness range:

-

0.5-1.0mm

-

Dimension:

-

2200*1100*1600

Product Description

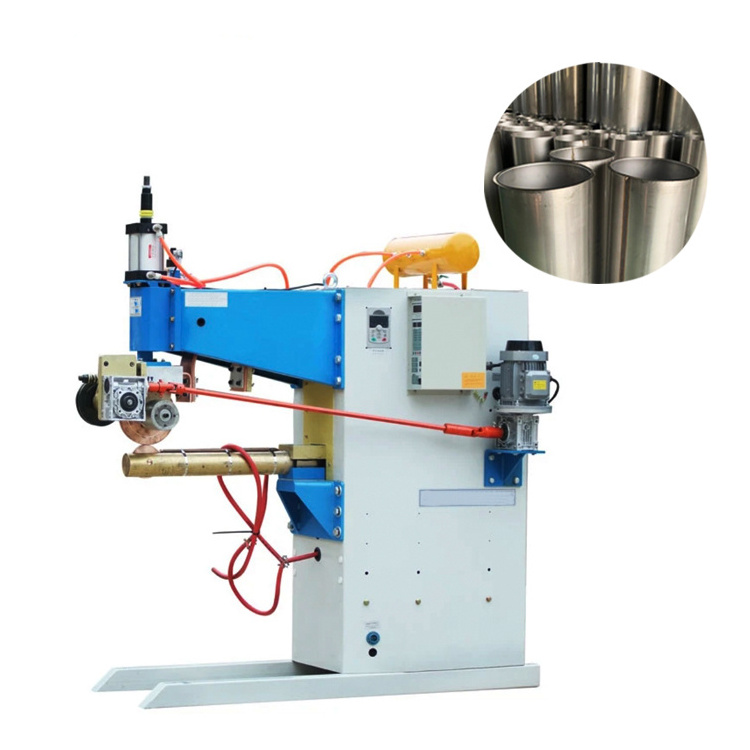

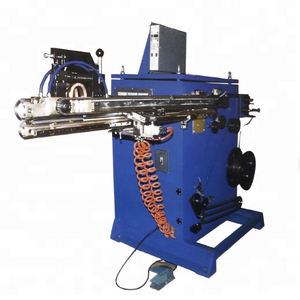

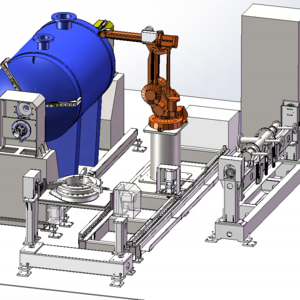

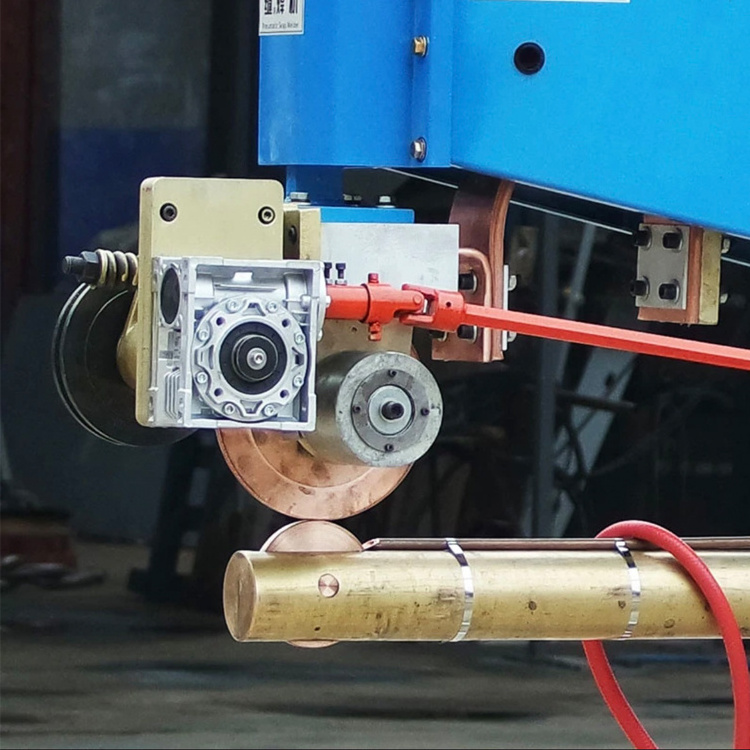

⭐Straight Seam Welding Machine⭐

Rod sewing machine refers to the welding parts assembled into a lap or butt joint and placed between two roller electrodes, roller electrode pressure rod and rotation, continuous or intermittent pulse power supply, forming a continuous weld resistance welding machine. Rod sewing machine is an evolution of point drying. Joint bars are widely used in the manufacture of joints requiring tightness, and sometimes are also used to weld ordinary sealing sheet metal parts.

Working principle:

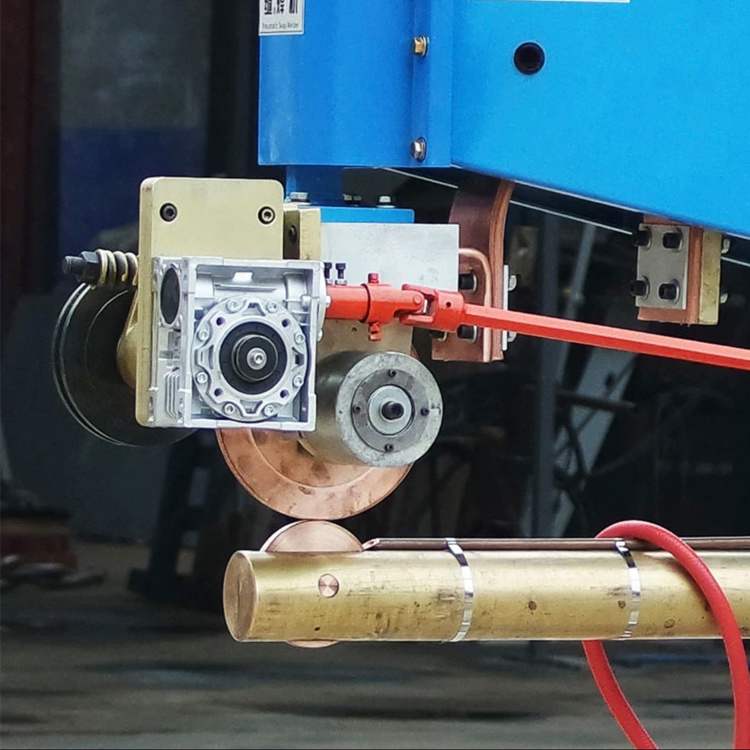

1. Power supply system⭐

The power supply system of the straight seam welding machine is mainly composed of three parts: transformer, rectifier and control system. The transformer raises the power frequency voltage to a high voltage and provides a stable current for the arc after rectification. The control system can monitor and regulate current and voltage.

2. Welding process⭐

The welding process of the straight seam welding machine is roughly divided into four stages: preheating period, fusion period, cooling period and blank pressing period.

3.Preheating period⭐

The arc is formed on the tube wall, the tube wall begins to heat, and after reaching a certain temperature, the tube wall begins to melt.

4.Fusion period⭐

A certain gap is left in the pipe seam, and the current and arc produce gas to form slag. The molten slag protects the molten pool and isolates the molten pool from the pipe wall.

5.Cooling period⭐

The molten pool and pipe wall are cooled down, the molten slag gradually solidifies, and the protective gas is released.

6.Blanking and flattening period⭐

The weld is shaped by the roll blanking and flattening mechanism.

Finished Product

Technical characteristics:

1. High welding quality⭐

Under the action of high temperature and high arc energy, the weld pool is fully mixed to achieve complete fusion. The weld has high quality, good surface flatness, and is not easy to produce quality problems such as cracks or pores.

2.High production efficiency⭐

In the melting process of the straight seam welding machine, there is a certain gap in the pipeline, which accelerates the melting speed and can greatly improve the production efficiency.

3.Save materials⭐

The weld quality of the straight seam welding machine is high, and metal materials can be saved.

4.Easy to operate⭐

The straight seam welding machine is easy to operate, and only a few people can complete large-scale welding work.

Application

Shipbuilding Industry

Motor Industry

Metal Products Industry

Medical Equipment

Specification

|

1

|

Power supply

|

380V±10%

|

|

2

|

Rated input voltage

|

40KVA

|

|

3

|

Duration of rated load

|

40%

|

|

4

|

Wire feed speed

|

6-12m/min

|

|

5

|

Wire diameter

|

2.0-2.2mm

|

|

6

|

Minimum diameter of welding workpiece

|

100mm

|

|

7

|

Maximum diameter of welding workpiece

|

500mm

|

|

8

|

Material for welding workpieces

|

Cold-rolled steel or tinplate

|

|

9

|

Thickness range

|

0.5-1.0mm

|

|

10

|

Dimension

|

2200*1100*1600

|

Packing and Shipping

Packaging:

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly.

Also we would like to have seamless cooperation with your forwarder at your convenience.

About Us

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Hot Searches