- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

20mm-110mm

-

Specification:

-

20mm-110mm

-

Length:

-

customized

-

Thickness:

-

2mm-18.3mm

-

Standard:

-

ISO

-

Color:

-

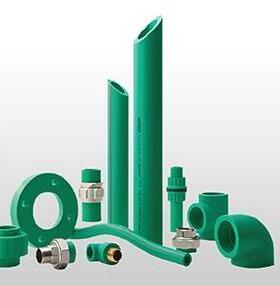

Green,white or as required

-

OEM:

-

Accpet

-

Usage:

-

Cold and hot water supply

-

Lifespan:

-

50 Years Under Normal Condition

-

Sample:

-

Freely Supplied

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Ritable

-

Model Number:

-

20mm-110mm

-

Specification:

-

20mm-110mm

-

Length:

-

customized

-

Thickness:

-

2mm-18.3mm

-

Standard:

-

ISO

-

Color:

-

Green,white or as required

-

OEM:

-

Accpet

-

Usage:

-

Cold and hot water supply

-

Lifespan:

-

50 Years Under Normal Condition

-

Sample:

-

Freely Supplied

Product Description

The raw material of PPR pipe is Polypropylene Random Copolymer (PPR-C). The production of ppr pipe should comply with ISO 15874 standards. The PPR pipes designed for the distribution of hot and cold water.

Basic Information

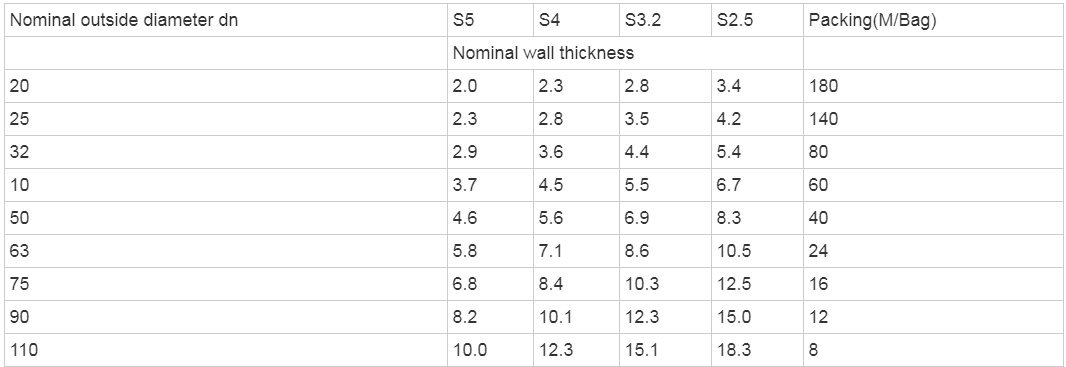

The ritai PP-R pipe has four series according to the sizes, which are S5, S4, S3.2 and S2.5. Each series has nine products: Φ20,Φ25, Φ32, Φ40, Φ50, Φ63, Φ75, Φ90, Φ110.

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Hebei

|

|

Brand Name

|

Ritable

|

|

Model Number

|

20mm-110mm

|

|

Material

|

PP

|

|

Specification

|

20mm-110mm

|

|

Length

|

customized

|

|

Thickness

|

2mm-18.3mm

|

|

Standard

|

ISO

|

|

Processing Service

|

Moulding, Cutting

|

|

Color

|

Green,white or as required

|

|

OEM

|

Accpet

|

|

Usage

|

Cold and hot water supply

|

|

Lifespan

|

50 Years Under Normal Condition

|

|

Sample

|

Freely Supplied

|

Product Advantage

Corrosion resistance:

PPR pipes have a low corrosion rate in water environments or when exposed to weathering agents such as atmospheric oxygen and carbon dioxide. Compared with a steel pipe which corrodes roughly at 10-6~10-5mm/year in normal conditions, the corrosion rates of PPR pipes are between 10-11~10-9mm/year. The anticorrosive performance of products is good enough to make them last longer than metal materials under the same environmental condition.

Lightweight:

The density of most plastic materials is usually lower than that of water, but the density of PPR is even less than half that of water. This not only makes transportation conditions better but also reduces the workload during laying and lifting operations.

Flexibility:

Compared with metal pipes (such as iron/steel or copper), plastic pipe has good flexibility; it can be wrapped around corners without sharp angles or bends, which makes it easier to install.

High durability:

Plastic pipe made of PPR material used for underground piping systems can last longer than steel mainlines in an under-ground environment due to its corrosion resistance, lightweight and flexibility features. Unlike common perception, plastic pipes do not easily break when bent too sharply at a small angle within 180 degrees.

Application Areas

2.Agricultural and horticultural usage of pipe

3.rainwater utilization systems networks

4.swimming pool pipe networks

5.Drinking water pipe and food industrial use.

Packing & Delivery

Packing with PP bag in strength or as customer required

Hot Searches