- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Biochar Pyrolysis Machine

-

Drum Speed(r/min):

-

2-3

-

Output Capacity(kg/h):

-

1200-1500

-

Feeding Way:

-

Automatic frequency conversion feeding

-

Control Cabinet:

-

PLC automatic control cabinet

-

Equipped With:

-

Cooling discharging machine

-

Production Status:

-

with carbonized color display

-

Raw Material:

-

Wood Sawdust, Rice Husk, Crops Straw, Coconut Shell, etc.

-

Usage:

-

Making Charcoal

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGLI

-

Weight (KG):

-

120000 KG

-

Product Name:

-

Biochar Pyrolysis Machine

-

Drum Speed(r/min):

-

2-3

-

Output Capacity(kg/h):

-

1200-1500

-

Feeding Way:

-

Automatic frequency conversion feeding

-

Control Cabinet:

-

PLC automatic control cabinet

-

Equipped With:

-

Cooling discharging machine

-

Production Status:

-

with carbonized color display

-

Raw Material:

-

Wood Sawdust, Rice Husk, Crops Straw, Coconut Shell, etc.

-

Usage:

-

Making Charcoal

Product Introduction

Applicable Material

Main Features

1. configuration the early stage of the new type gasifier gasification; 2. configuration of flue gas purification, heat exchange system, cooling system, heat steam into water, flue gas can be converted to gas recycling; 3. configuration frequency conversion feeding machine, automatic feeding, feeding speed is adjustable; 4. configuration rotary carbonation host, meet the production requirements; 5. configuration cooling discharging machine cooling products, output, product; 6. configuration control cabinet, temperature, speed regulation, drum PLC automatic control cabinet, the equipment for carbonized color display, production status should be clear;

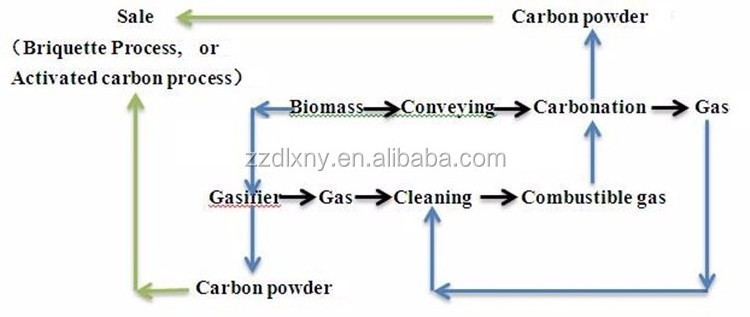

Below is Biochar Pyrolysis Process

First the biomass material is ignited in the gasifier.

The flue gas produced by burning after spraying, cooling, purification process, it produces the pure combustible gas (carbon monoxide, methane, ethane, etc.).

As the early stage of the

biochar pyrolysis

of heat source, through early warming of the

biochar pyrolysis

, to feed the material when the heat reaches the special temperature.

The combustible gas that

biochar pyrolysis

process of flue gas by spraying, cooling, purification process into burned secondary. According to this methods of circulation, sufficient to achieve a self-sufficient, then achieve the effect of energy saving.

The flue gas through purification, to reach the environment production and flue gas emissions free. Which is reached to the standards of waste gas emptying.

The temperature of

biochar pyrolysis

reach a 600 ℃ to 900 ℃ in the process. According to the characteristics of material, the temperature can be adjusted according to the requirements.

Below is Working Principle

|

Model

|

diameter(mm)

|

The drum length(m)

|

host RPM(revolutions per minute)

|

Carbon capacity(kg/h)

|

Power

(kw) |

Dimension

(m) |

|

DLTJ1210

|

1200

|

10

|

2-5

|

200-300

|

40-50

|

11*2.0*2.8

|

|

DLTJ1410

|

1400

|

10

|

2-4

|

400-500

|

50-70

|

11*2.2*3.0

|

|

DLTJ1612

|

1600

|

12

|

2-4

|

600-800

|

70-80

|

11*2.5*3.3

|

|

DLTJ1912

|

1200

|

12

|

2-3

|

900-1100

|

90-110

|

13.5*2.8*3.6

|

|

DLTJ2212

|

1400

|

12

|

2-3

|

1200-1500

|

110-130

|

13.5*3.0*4.0

|

Below is Dingli Group Packaging & Shipping:

Your device will be packed well in container and suit for long ocean shipping.

Below are Dingli Dryer Factory & Sales Team & Production Workshop Pictures:

Below are Dingli Customers Visiting:

Dingli Dryer Production Line has exported to over 80 countries with 300 foreign partners, such as Germany, Britain, United States, Italy, Israel, Chile, Thailand, Russia, Vietnam, India, Cambodia, Indonesia, Malaysia, Thailand etc.