- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

140

-

Elongation (≥ %):

-

25-10

-

Specification:

-

Rectangular 150-140

-

Grade:

-

Cu-DHP, Cu-Ag, Cu-Cr-Zr

-

Length:

-

800-900mm

-

Wall Thickness:

-

6-50mm

-

Outside Diameter:

-

150*140mm

-

Place of Origin:

-

China

-

Color:

-

Copper Nature

-

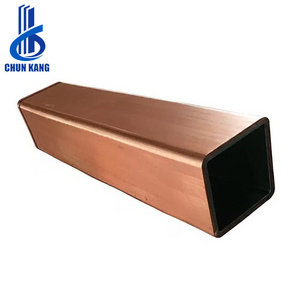

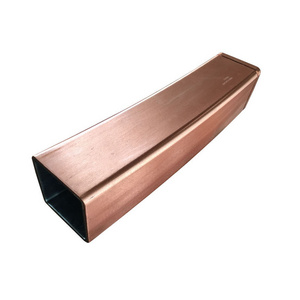

Surface:

-

Polished

-

Casting Machine Radius:

-

6000-8000mm

Quick Details

-

Type:

-

Straight Copper Pipe

-

Cu (Min):

-

99%

-

Alloy Or Not:

-

Is Alloy

-

Ultimate Strength (≥ MPa):

-

140

-

Elongation (≥ %):

-

25-10

-

Specification:

-

Rectangular 150-140

-

Grade:

-

Cu-DHP, Cu-Ag, Cu-Cr-Zr

-

Length:

-

800-900mm

-

Wall Thickness:

-

6-50mm

-

Outside Diameter:

-

150*140mm

-

Place of Origin:

-

China

-

Color:

-

Copper Nature

-

Surface:

-

Polished

-

Casting Machine Radius:

-

6000-8000mm

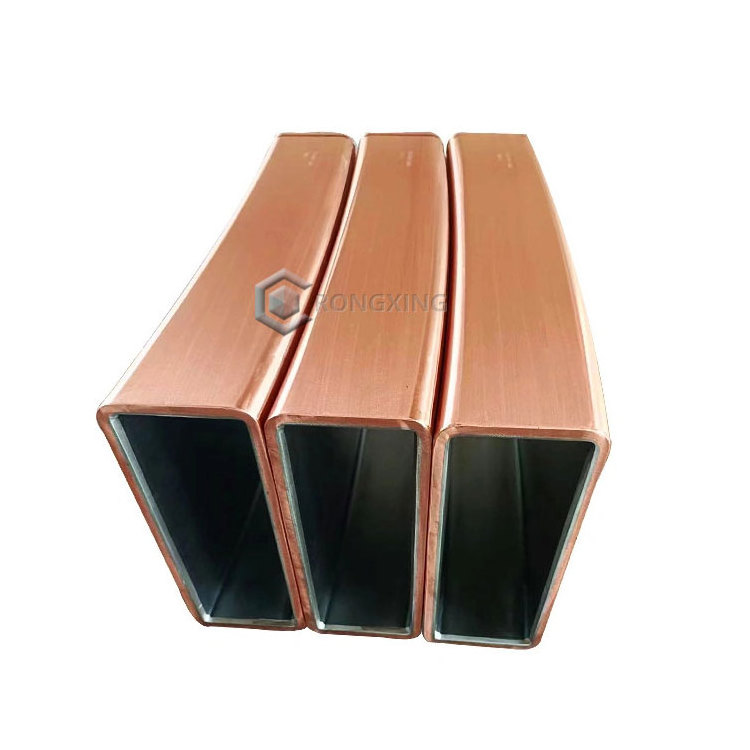

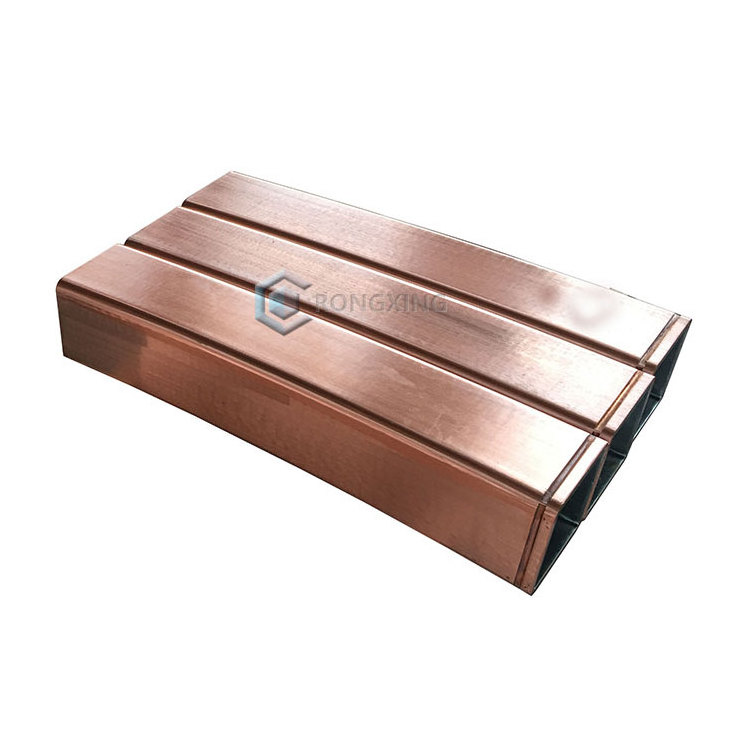

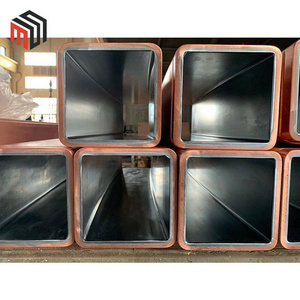

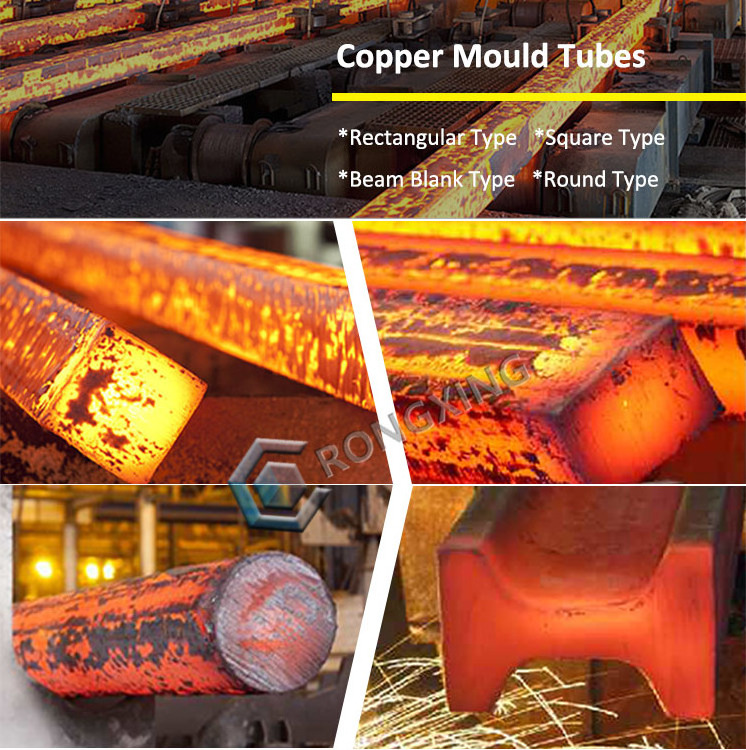

Rectangular Type Copper Mould Tube

Product Parameters

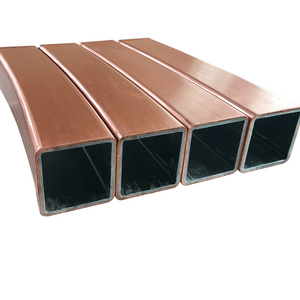

Copper Mould Tube includes square type, rectangular type, round type, H beam blank type and other non-standard copper mould tubes.

| Copper Mould Tube | |||||

| Item | Unit | Size | Thickness | Length | Radius |

| Square Copper Mould Tubes | mm | 50*50-500*500 | 6-50 | 700-1100 | 4000-17000 or Straight |

| Round Copper Mould Tubes | mm | φ110-1200 | 10-50 | 700-900 | 5000-17000 or Straight |

| Rectangle Copper Mould Tubes | mm | (100-500)*650 | 6-50 | 700-1100 | 4000-17000 or Straight |

| Beam Blank Copper Mould Tubes | mm | Customized | 12-50 | 780-1016 | 6000-17000 |

| Non-standard Copper Mould Tubes | mm | Customized | 12-50 | 780-1016 | 6000-17000 |

| Metallurgy of Copper Mould Tubes | |||

| Material | Cu-DHP | Cu-Ag | Cu-Cr-Zr |

| High Phosphorus Deoxidized Copper | Cu-Ag(Cu-0.1Ag) | Cu-Cr-Zr(Cu-0.6Cr-0.15Zr) | |

| Properties | Normal Deoxidized Copper | Through the addition of about 0.1% silver,strength is significantly enhanced with no loss in thermal conductivity | Cr and Zr precipitation hardening provides this alloy with high strength, high resistance to heat, and thermal conductivity |

| Melting point | 1083 ℃ | 1083 ℃ | 1078 ℃ |

| Coefficient of thermal expansion at 20℃ | 1.68*10-5 | 1.68*10-5 | 1.70*10-5 |

| Thermal | 340w(m.K) | 377w(m.K) | 325w(m.K) |

| Recrystallization | 330 ℃ | 370 ℃ | 700 ℃ |

| Hardness at 20℃ | Min.85HB | Min.90HB | Min.120HB |

| Complete technical data, Please contact us for catalog. | |||

| Item | Sectional Dimension (mm) | CCM Radius (mm) | Length (mm) |

| Rectangular Type Copper Mould Tube | 150*140 | R=6000-8000 | L=800-900 |

| 150*155 | |||

| 180*240 | R=8000-9000 | L=900 | |

| 165*225 | |||

| 160*220 | R=6000-9000 | ||

| 120*220 | |||

| 165*280 | R=9000-10000 | ||

| 175*285 | R=6000-9000 | ||

| 130*285 | R=6500-8000 | ||

| 155*185 | R=6000-8000 | ||

| 140*155 | |||

| 155*165 | |||

| 150*245 | R=6000-10000 | ||

| 165*285 | |||

| 120*225 | |||

| 130*135 | |||

| 150*520 | |||

| 150*490 |

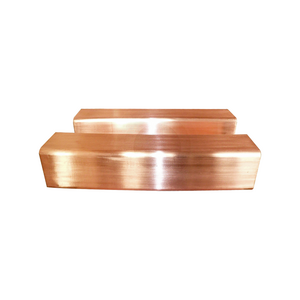

Superior Quality

To provide mould tubes with optimal physical and mechanical properties to customers' specifications, mould tube products are supplied of the following materials:

Cu-DHP : Normally used for mould tubes section size below 180x180mm and round tubes below Dia.150mm.

Cu-Ag : Normally used for mould tube section size above 180x180mm and round tubes above Dia.150mm

Cu-Cr-Zr : Normally used for beam blank mould tubes

These materials have different levels of hardness and thermal conductivities. We are highly experienced in choosing proper materials to meet the specific demands in heat resistance and thermal conductivities of customers' applications.

Production Process:

Melting & Casting --- Hot Extrusion/Forging --- Cold Drawing --- Tapering --- Machining --- Electroplating --- Machining after Electroplating --- Final Inspection --- Packing

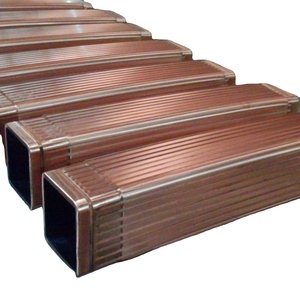

Advantages of Rongxing Copper Mould Tubes:

• Uniform shell growth,Optimum billet quality

• Reliable quality

Created copper mould tube with good raw materials, produce copper mould tube products based on industry norms and high standards.

• Special coatings. Increase erosion resistance and service life

We always dedicated to research special coatings. The mould tubes can be c oated with our different types of internal surface coating: Cr, Ni-Co, Ni-Fe, Ni-Co-Cr. The coating thickness has been controlled in the best range.

• Customized and low cost.

You might order copper mould tube according to your industrial needs. We help you to produce these products on your limited budget to access on your field.

Cu-DHP : Normally used for mould tubes section size below 180x180mm and round tubes below Dia.150mm.

Cu-Ag : Normally used for mould tube section size above 180x180mm and round tubes above Dia.150mm

Cu-Cr-Zr : Normally used for beam blank mould tubes

These materials have different levels of hardness and thermal conductivities. We are highly experienced in choosing proper materials to meet the specific demands in heat resistance and thermal conductivities of customers' applications.

Production Process:

Melting & Casting --- Hot Extrusion/Forging --- Cold Drawing --- Tapering --- Machining --- Electroplating --- Machining after Electroplating --- Final Inspection --- Packing

Advantages of Rongxing Copper Mould Tubes:

• Uniform shell growth,Optimum billet quality

• Reliable quality

Created copper mould tube with good raw materials, produce copper mould tube products based on industry norms and high standards.

• Special coatings. Increase erosion resistance and service life

We always dedicated to research special coatings. The mould tubes can be c oated with our different types of internal surface coating: Cr, Ni-Co, Ni-Fe, Ni-Co-Cr. The coating thickness has been controlled in the best range.

• Customized and low cost.

You might order copper mould tube according to your industrial needs. We help you to produce these products on your limited budget to access on your field.

Packaging & Shipping

Customers

Hot Searches