- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Computer-controlled continuous cutting machine

-

Cutting force:

-

80 tons

-

Cutting plate:

-

1600*800 or your customize

-

Motor:

-

7.5kw

-

Stroke:

-

50-230

-

Application1:

-

Computer-controlled continuous cutting machine

-

Application2:

-

shoes clicking press machine

-

Application3:

-

leather clicking press machine

-

Packaging Details::

-

wooden case with plastic film...

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JSATON

-

Model Number:

-

JSAT

-

Type:

-

Computer-controlled continuous cutting machine

-

Cutting force:

-

80 tons

-

Cutting plate:

-

1600*800 or your customize

-

Motor:

-

7.5kw

-

Stroke:

-

50-230

-

Application1:

-

Computer-controlled continuous cutting machine

-

Application2:

-

shoes clicking press machine

-

Application3:

-

leather clicking press machine

-

Packaging Details::

-

wooden case with plastic film...

The working principle of the hydraulic cutting machine is down press to the mold,to cut material by dies / molds.

We can make the machine according to your specifically order, for example the color, the motor information ,the working table, the traveling head size etc.

Computer-controlled continuous cutting machine with clamping feeding device for roll materials

1. Technical Parameters

|

model |

JSAT 1- 800 |

J SAT 1- 1000 |

J SAT 1- 1500 |

|

M ax cutting machine |

80T |

100T |

150T |

|

D istance between pressing board and working platform |

50-240mm |

50-230mm |

50-230mm |

|

E ffective area of working platform |

1600*800mm |

1600*800mm |

1600*900mm |

|

P ower of main motor |

7.5kw |

7.5kw |

11kw |

|

F eeding mechanism |

1.1kw |

1.1kw |

1.1kw |

|

weight |

6800kg |

8800kg |

12500kg |

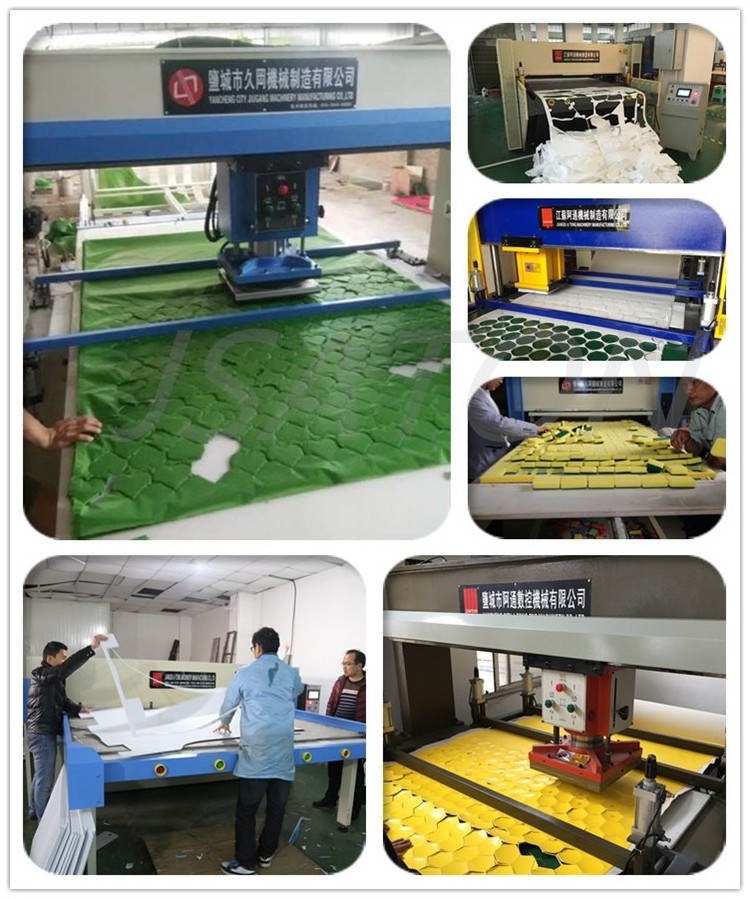

2. Features and Advantages

The machine is a large sized automatic continuous cutting machine which is applicable for cutting roll materials such as car floor mats, seats ,ceilings and steering wheels in automobile interior decoration industry ,backing plate leather ,floor tiles and carpets in decorative material industry, sand paper polished wafer and polished wheel in abrasive industry ,as well as football and volleyball in ball manufacturing industry.

1. Large-tonnage precision four-column double-cylinder double-link automatic balancing mechanism to ensure the cutting speed and accuracy of the machine, all sliding joints using central automatic lubrication device, so that wear and tear to a minimum.

2. The conveying part adopts PLC control. The servo motor drives the material to be inputted from one side of the machine. After cutting, the output from the other side ensures the feeding precision and smooth running. The feeding length can be adjusted by the touch screen. Display information to facilitate machine maintenance.

3. Servo motor clamping feed, receiving device, so that the control accuracy of ± 0.2mm.

4. Cutting under pressure when the first 10mm in contact with the knife before the automatic slow speed, so that when cutting multi-layer material, the top and bottom of the size of the error is not.

5. Due to the accuracy of the cutting balance, it can greatly reduce the loss of the cutter die and the cutting board, the edge effect is better, and the consumption of the cutting board is reduced.

6. Unique mold set structure, with the cutter and cutting height, so that stroke adjustment is simple and accurate.

7. Die fixed clamping device, easy to replace the cutter mold.

3

.

O

ur

machine working show

4 . The cutting-dies

5 .What Applications of our cutting machine?

Application Materials:

The Cutting Machine is widely used in industrial leather,plastic,rubber,sponge,foam,EVA,PVC,cardboard,paper products,fabric,home textiles,packaging materials,non woven,carpet,car cushion,felt,synthetic materials,and other non-metallic materials in various industries;Extremely suitable for cutting multiple layers of material at one time, etc.