- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Year:

-

2019

-

Brand Name:

-

OEM

-

Dimension(L*W*H):

-

244*135*173cm Or customized

-

Weight (KG):

-

1000

-

Material:

-

Stainless Steel 304/316

-

Bottle, can, jar, bag type:

-

Round or shaped,

-

Speed:

-

adjustable

-

Filling range:

-

Choosed

-

Control:

-

Atuomatic

-

Packaging Type:

-

wood case

-

Machinery Capacity:

-

8000BPH

-

Filling Material:

-

liquid

-

Core Components:

-

Engine

-

After Warranty Service:

-

Video technical support

Quick Details

-

Production Capacity:

-

10000

-

Application:

-

products in bottle or jar, bottle, can, jar, filling and labeling

-

Voltage:

-

110-240

-

Place of Origin:

-

Guangdong, China

-

Year:

-

2019

-

Brand Name:

-

OEM

-

Dimension(L*W*H):

-

244*135*173cm Or customized

-

Weight (KG):

-

1000

-

Material:

-

Stainless Steel 304/316

-

Bottle, can, jar, bag type:

-

Round or shaped,

-

Speed:

-

adjustable

-

Filling range:

-

Choosed

-

Control:

-

Atuomatic

-

Packaging Type:

-

wood case

-

Machinery Capacity:

-

8000BPH

-

Filling Material:

-

liquid

-

Core Components:

-

Engine

-

After Warranty Service:

-

Video technical support

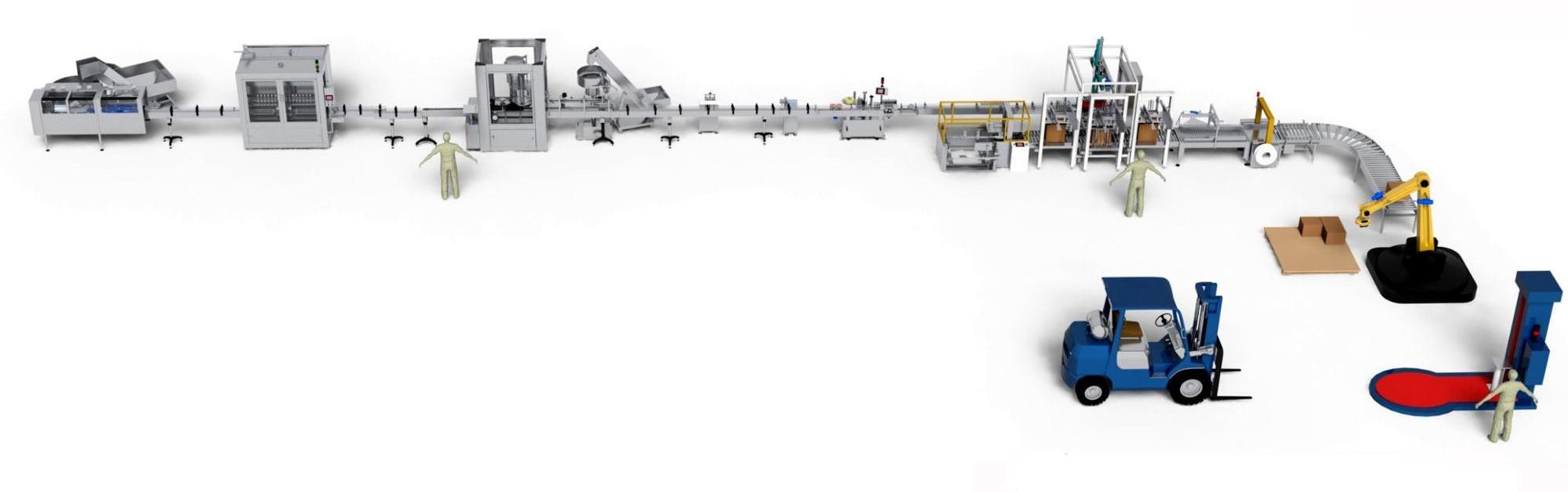

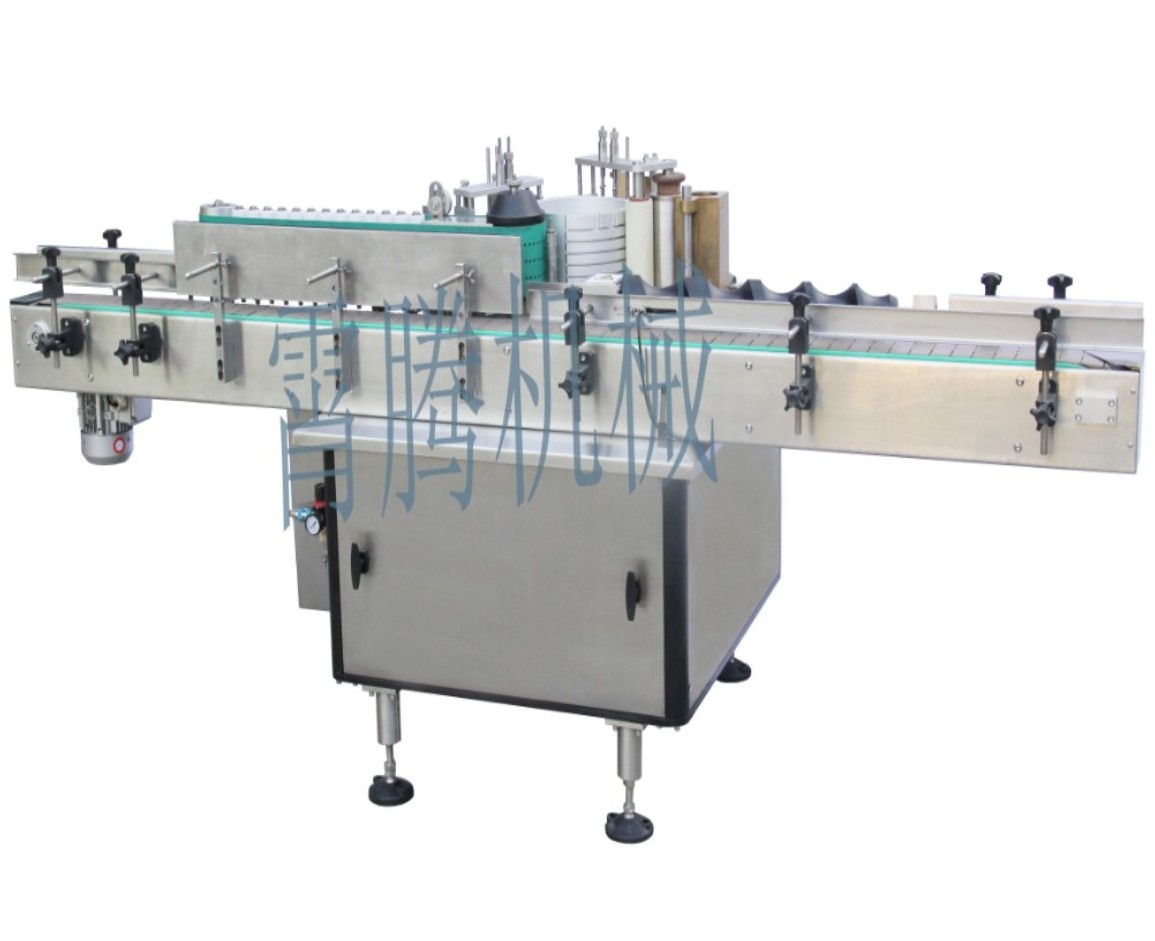

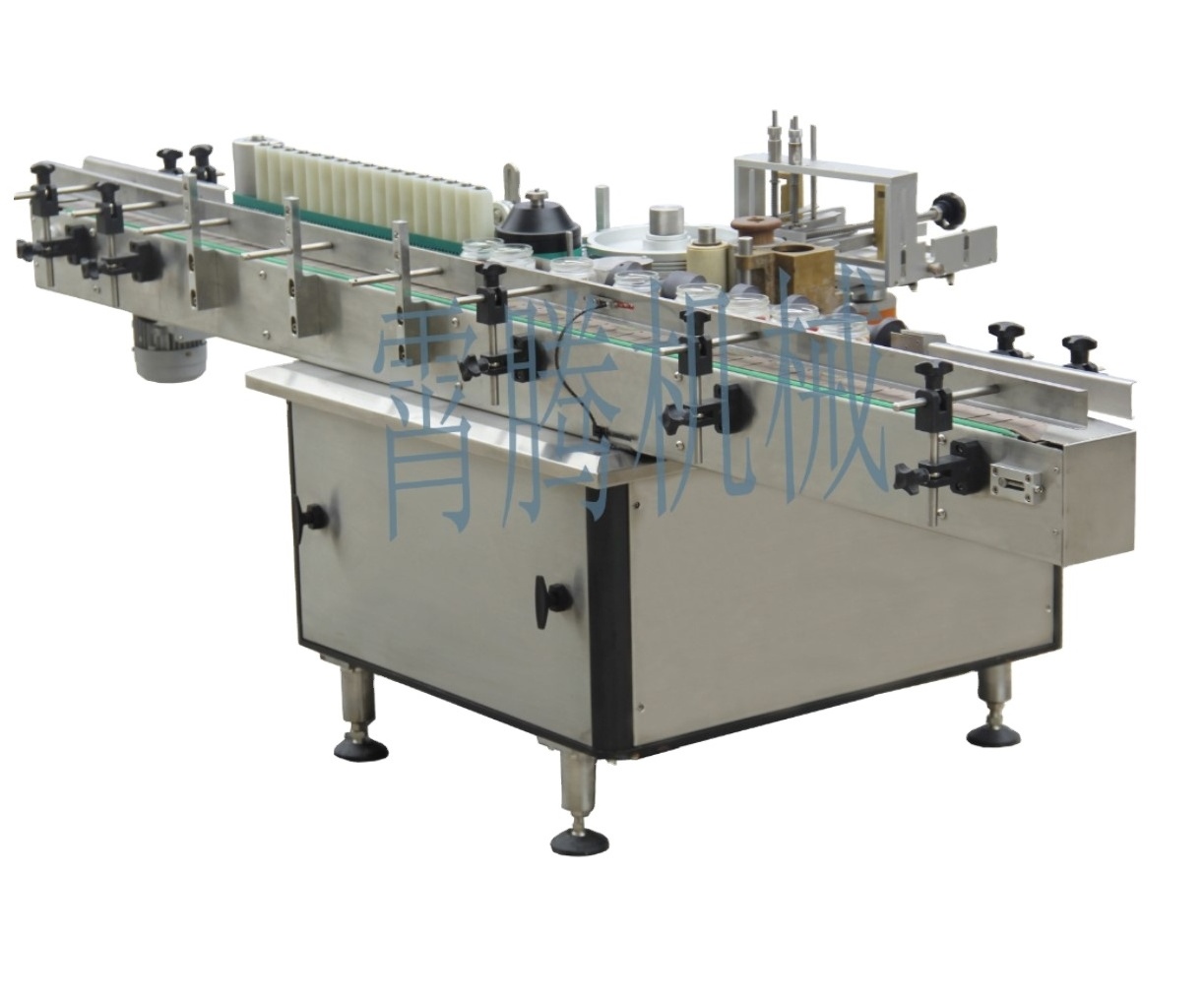

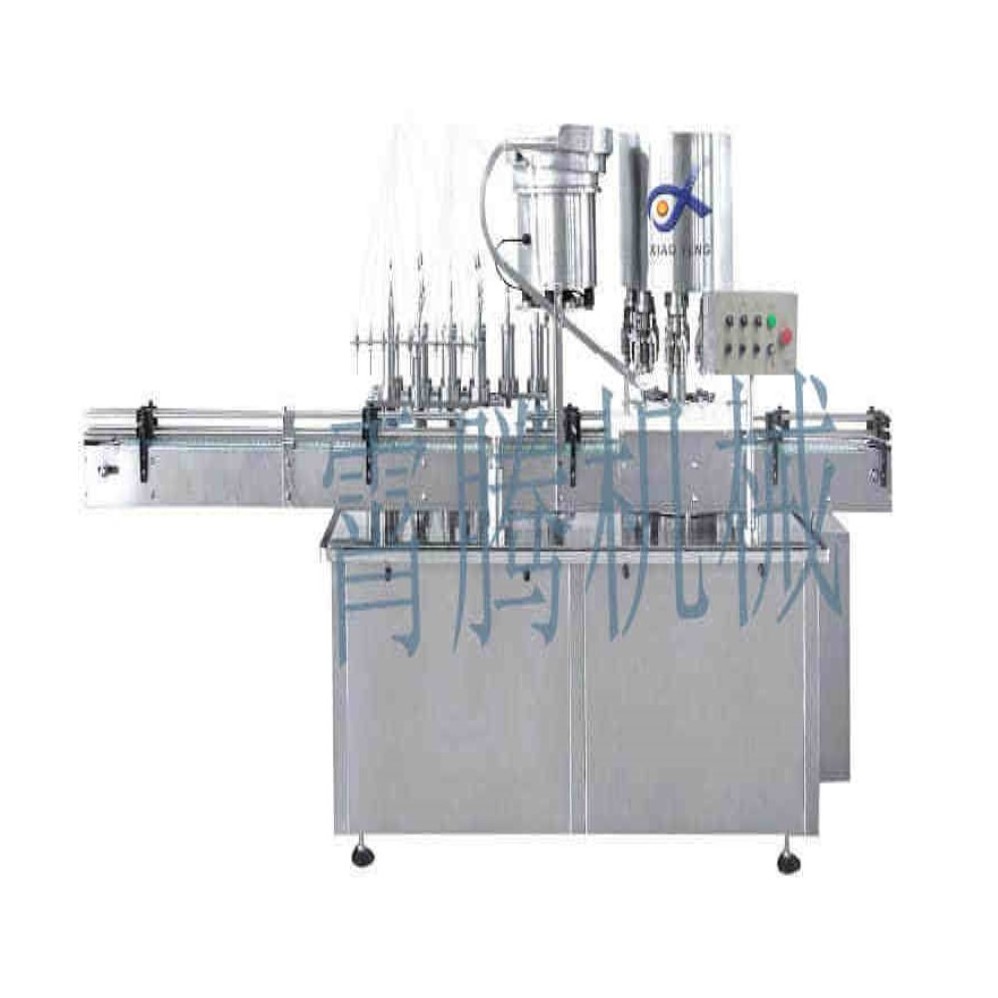

Factory Semi Automatic Cans Jar Bottles Labeling Machines Automatic Liquid Filling Machines

(Price and Packing and Shipping cost will be quoted you after learnt your detail request(such as bottle size, capacity, speed, etc.)

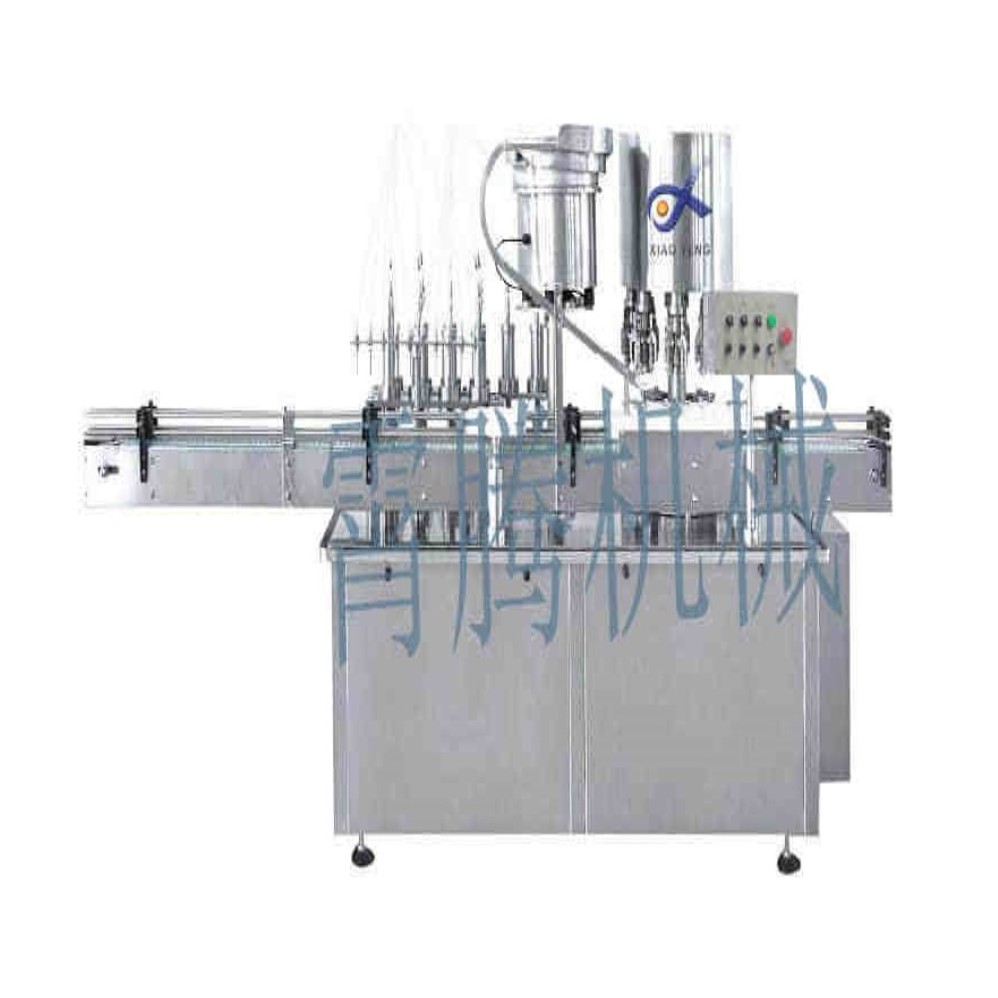

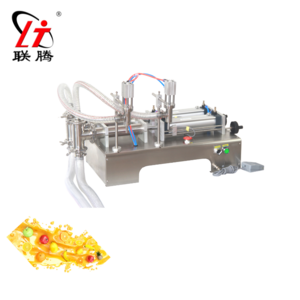

1. This machine is mainly applicable to filling/capping operation for 20ml, 30ml, 50ml 75ml, 1000m, 1500ml, 2000ml, 3000m, etc plastic or glass bottles for cosmetics, water, juice, bear, oil, laundry detergent, etc,10 pumps are used for double-headed filing/capping.In order to increase corresponding output, stainless steel pumps can be added. This machine structure allows filling production for high-capacity liquid like large infusion,syrup etc,This machine has simple structure,is convenient in maintenance and easy for operation.It is advised to choose corresponding electric configuration and dust cover .

2. Main features and performance:

Bottle feeding, filling and plug putting are on dual rails; linear bottle feeding; liquid level filled can be tracked and controlled by stainless steel valve to ensure there is no adherent liquid and dropping liquid; detect with optical fiber; plug putting by cylinder; stop putting inner plug with no bottles there; percent of pass of putting plug is high.

3. Good safety barrier propterty; Convenient to operate, adopting selective screen to operate.

4.Widely used for the volume production of infusion solutions in bigger bottles and large capacity vaccine.

| Application | Filing for liquid and sealing |

| Material | Safty |

| Certificate | CE, RoHS |