- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1000 kg

-

Application:

-

Industry Fuel, Biogas purification

-

Material:

-

Steel

-

Feature:

-

High efficiency,less than 10ppm

-

Installation:

-

Quick and easy

-

Service life:

-

More than 10 years

-

Desulfurization way:

-

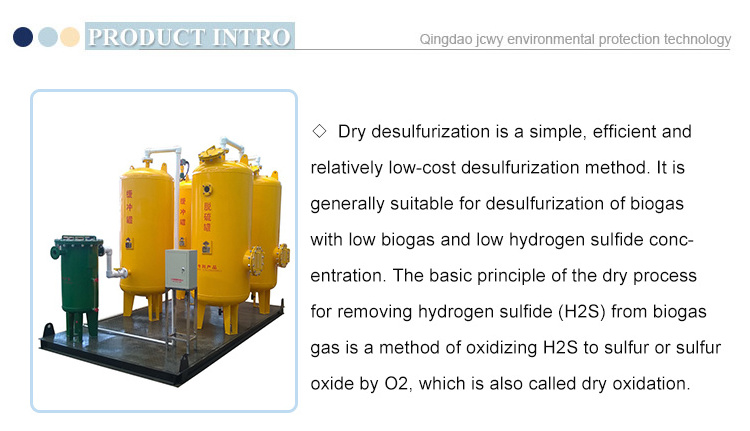

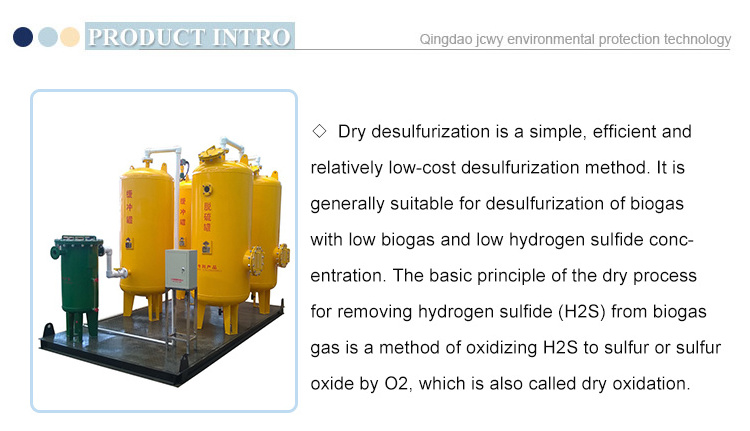

Dry desulfurization

-

Surface treatment:

-

Sand blasting and spray paint

-

Internal treatment:

-

Anti-corrosion coating

-

Control system:

-

Full automatic control

-

Color:

-

Customerized

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JCWY

-

Purify Efficiency:

-

95%

-

Weight (KG):

-

1000 kg

-

Application:

-

Industry Fuel, Biogas purification

-

Material:

-

Steel

-

Feature:

-

High efficiency,less than 10ppm

-

Installation:

-

Quick and easy

-

Service life:

-

More than 10 years

-

Desulfurization way:

-

Dry desulfurization

-

Surface treatment:

-

Sand blasting and spray paint

-

Internal treatment:

-

Anti-corrosion coating

-

Control system:

-

Full automatic control

-

Color:

-

Customerized

Product Description

Biogas Purification Equipment Description:

Thanks to the development of several technological bricks, including the CO2 separation membranes our solutions enable you to upgrade all biogases for injection into the natural gas grid, the production of vehicle fuel, liquid biomethane, and the production of renewable hydrogen. The modular systems designed and developed by Air Liquide are upgradeable biogas processing units with processing capacities that range from a hundred to several thousand m3 an hour (100 to 10,000 Nm3/h).

Thanks to the development of several technological bricks, including the CO2 separation membranes our solutions enable you to upgrade all biogases for injection into the natural gas grid, the production of vehicle fuel, liquid biomethane, and the production of renewable hydrogen. The modular systems designed and developed by Air Liquide are upgradeable biogas processing units with processing capacities that range from a hundred to several thousand m3 an hour (100 to 10,000 Nm3/h).

|

Dimensions for desulfurizer pellet

|

dia 5 - 6 *5 - 30mm

|

|

Ferric Oxide content

|

25% - 33%

|

|

Density

|

0.85kg/L

|

|

Filter contains

|

200kg in tank

|

|

Porosity

|

50 - 60%

|

|

Tank material

|

stainless steel

|

|

biogas treating capacity

|

less than 400 m3 per day

|

|

Regeneration

|

two times

|

|

H2S removal efficiency

|

over 99% percent

|

Our system has the following functions:

1. Desulfurization

Hydrogen sulfide can be reduced to 50ppm or less;

2. Dehydration

Removal of saturated water vapor;

3. Impurity removal.

Removal of physical impurities and volatile matter of desulphurizer agent;

4. Pressure increasing

Increment could reach 39.8 kPa or even higher;

5. Pressure stabilization

Stabilizing gas outlet pressure at a fixed value to meet the gas intake pressure requirement of the follow-up equipment;

6. Measurement of Pressure and hydrogen sulfide content (optional);

7. Digital display.

Pressure setpoint, gas outlet pressure, motor frequency, motor speed, motor current, output torque, bus voltage, output voltage, power consumption and system operation time would be indicated on the LCD display.

Working principle

First step: Fe2O3 · H2O + 3 H2S = Fe2S3 + 4 H2O (desulfuration)

Second step: Fe2S3 + 3/2 O2 + 3 H2O = Fe2O3 · H2O + 2 H2O + 3 S (regeneration)

Second step: Fe2S3 + 3/2 O2 + 3 H2O = Fe2O3 · H2O + 2 H2O + 3 S (regeneration)

Our Advantages

1. Easy to install and easy to use.

2. During the work process, no personnel are required to be on duty, and the materials are renewed regularly.

3. The desulfurization efficiency is high, and the effect of recycling can be achieved by oxidation reduction in the later stage.

4. Fine desulfurization, high precision of desulfurization.

5. Initially low investment and medium operating costs.

2. During the work process, no personnel are required to be on duty, and the materials are renewed regularly.

3. The desulfurization efficiency is high, and the effect of recycling can be achieved by oxidation reduction in the later stage.

4. Fine desulfurization, high precision of desulfurization.

5. Initially low investment and medium operating costs.

Product Application

It is mainly used for the removal of corrosive hydrogen sulfide (H2S) gas in biogas, and can also be used for other purification of hydrogen sulfide gas, so that the treated gas provides safety for the normal use and service life of the required equipment.

Packing & Delivery

Hot Searches