- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen machinery

-

Voltage:

-

380 volt

-

Power:

-

/

-

Dimension(L*W*H):

-

/

-

Weight:

-

0 kg

-

Output paper:

-

tissue paper, toilet paper, napkin paper, facial paper, hand towel

-

Raw material:

-

waste paper, wood pulp, bagasse, cotton, wheat straw

-

Output paper weight:

-

13-30g/m2

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

Egypt

Quick Details

-

Production Capacity:

-

2-10t/d

-

Product Type:

-

tissue paper making machine

-

Processing Type:

-

paper making machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen machinery

-

Voltage:

-

380 volt

-

Power:

-

/

-

Dimension(L*W*H):

-

/

-

Weight:

-

0 kg

-

Output paper:

-

tissue paper, toilet paper, napkin paper, facial paper, hand towel

-

Raw material:

-

waste paper, wood pulp, bagasse, cotton, wheat straw

-

Output paper weight:

-

13-30g/m2

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

Egypt

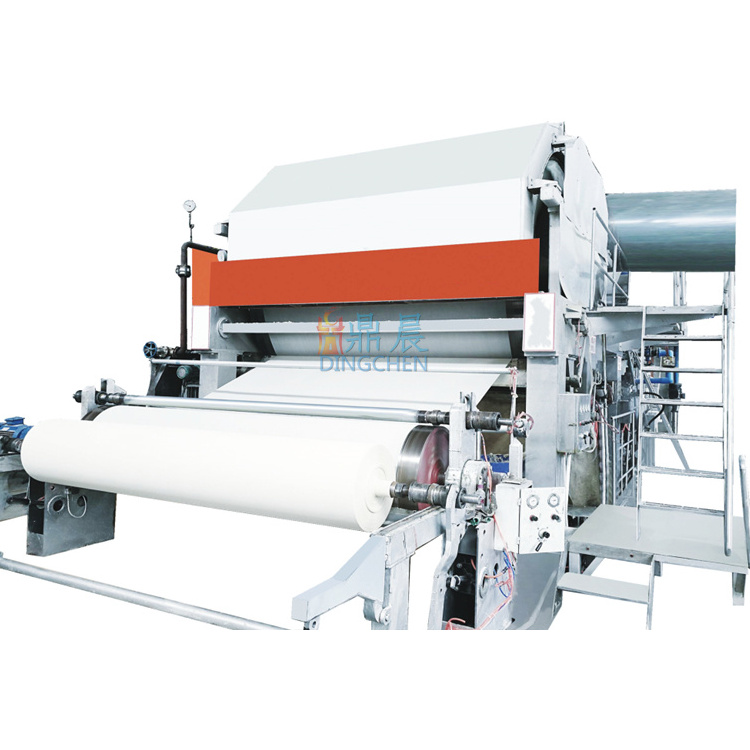

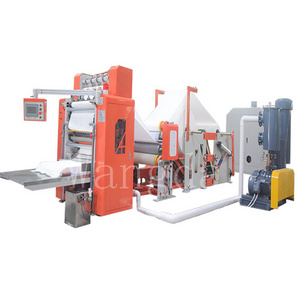

Facial tissue paper machine

Technical parameter

1) Raw material : recycled paper, or wood pulp

2) Output paper : toilet paper, tissue paper, hand towel

3) Output paper weight : 13-30 g.s.m.

4) Capacity : 6-7 ton per day

5) Net paper width : 2100mm

6) Cylinder mold width : 2550mm

7) Rail gauge : 3000mm

787- 2880mm 1-10 ton per day

8) Drive way : AC frequency inverter adjustable speed, section drive.

The structure and specifications of paper machine

1) Cylinder mold part

1 set of dia.1800mm×2550 mm×3000mm Cylinder mold

1 pc of dia. 450mm×2550mm×3000mm Couch roll

2) Dryer part

1 set of dia.2500mm×2550mm×3000mm dryer cylinder

1 pc of dia.550mm×2550mm×3000mm Touch roll

1 set of dryer hood with fan

2 sets of blade

3) Pope reeler part

With dia.900mm×2550mm×3000m winding cylinder

4) Vacuum part

Water suction box

Roots vacuum pump

5) Felt cleaning part

High pressure water pump

Movable water pipes

6) Operating part

Frequency converting panel

Main equipment for stock preparation

|

No |

Item &description |

Function |

|

1 |

hydra-pulper |

To break the waste paper into pulp and drop down the impurity and ink |

|

2 |

High frequency vibrating screen

|

To separate and remove the small impurity(such as broken plastic ,etc) in the pulp through vibrating |

|

3 |

Φ700mm impeller |

To stir the pulp and make sure the pulp and water mixed well |

|

4 |

Bleacher |

To whiten and clean the pulp |

|

5 |

6 inch pulp pump

|

providing the pulp for the needed machine |

|

6 |

8 inch water pump |

providing clean water for needed section |

|

7 |

Φ380mm double disc pulp refiner |

Grinding pulp and make it finer |

|

8 |

606 type sand remover |

To remove sand in the water |

|

9 |

0.6 m2 pressure screen

|

Separate long fiber and short fiber more finely |

|

10 |

Electric operating panel |

controlling equipment |