Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GSmach

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

15m*2.5m*2.8m

-

Power (kW):

-

132

-

Weight:

-

23000 KG

-

Machine size:

-

22.3*7.6*3.1m

-

Name:

-

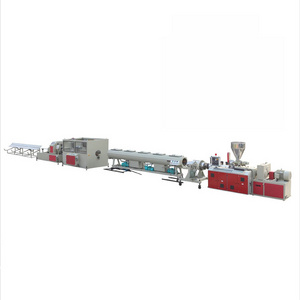

Kneader two stage extruder for Filler masterbatch granulator

-

Capacity:

-

100-1500kg/h

-

Feature:

-

color/filler masterbatch machine

-

Characteristic:

-

High output

-

Extruder Type:

-

Compounding

-

extruder motor:

-

132KW

-

Description:

-

plastic compounds extruder

-

Type:

-

plastic compounding line

-

Kneader motor:

-

220kw

Quick Details

-

Screw Design:

-

other

-

Screw L/D Ratio:

-

44:1

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GSmach

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

15m*2.5m*2.8m

-

Power (kW):

-

132

-

Weight:

-

23000 KG

-

Machine size:

-

22.3*7.6*3.1m

-

Name:

-

Kneader two stage extruder for Filler masterbatch granulator

-

Capacity:

-

100-1500kg/h

-

Feature:

-

color/filler masterbatch machine

-

Characteristic:

-

High output

-

Extruder Type:

-

Compounding

-

extruder motor:

-

132KW

-

Description:

-

plastic compounds extruder

-

Type:

-

plastic compounding line

-

Kneader motor:

-

220kw

Products Description

Advantages:

1. The machine adopts big brand parts, highly automatic controlling system, which is easy to operate and stable quality, and the

service life will be greatly extended as well.

2. This line has good mixing, dispersion and extrusion performance stable , which will help make top quality granules.

3. Usually the first compounding extruder runs at a high speed for good mixing and high output capacity, the second extruder must

be a larger diameter single screw that can run at lower screw speed.The granules quality extrusion will be more stable.

4. The lower screw can avoid over - heating by internal cooling system and strong heat exchange ability.

5. The functional separation allows operator to more flexibly control the expectable material mixing process and temperature.

Double stage extruder

:

1. The machine adopts big brand parts, highly automatic controlling system, which is easy to operate and stable quality, and the

service life will be greatly extended as well.

2. This line has good mixing, dispersion and extrusion performance stable , which will help make top quality granules.

3. Usually the first compounding extruder runs at a high speed for good mixing and high output capacity, the second extruder must

be a larger diameter single screw that can run at lower screw speed.The granules quality extrusion will be more stable.

4. The lower screw can avoid over - heating by internal cooling system and strong heat exchange ability.

5. The functional separation allows operator to more flexibly control the expectable material mixing process and temperature.

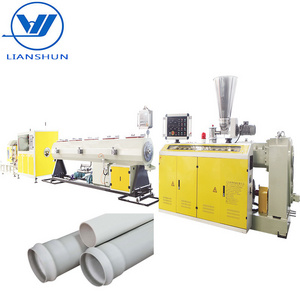

The first stage is co-rotating parallel twin screw extruder for dispersion and distribution.

The second stage is single screw extruder for cooling and pelletizing.

Two Types of Process:

1) Kneader + Conical Force Feeding + Twin Screw Extruder + Single Screw Extruder + Air Cooling Die Face Pelletizing

1) Kneader + Conical Force Feeding + Twin Screw Extruder + Single Screw Extruder + Air Cooling Die Face Pelletizing

2)

Kneader + Conical Force Feeding + Single Screw Extruder + Air Cooling Die Face Pelletizing

|

Model

|

Kneader

|

Motor power

|

L/D

|

Screw Dia.

|

Output

|

|

GSJ-50/100

|

55L

|

75KW

|

36-48:1

|

50.5/100mm

|

120-400kg/h

|

|

GSJ-65/150

|

75L

|

110KW

|

36-48:1

|

62.4/150mm

|

200-850kg/h

|

|

GSJ-75/180

|

110L

|

160KW

|

36-48:1

|

71/180mm

|

300-1250kg/h

|

|

GSJ-95/200

|

115L

|

220KW

|

36-48:1

|

93/200mm

|

750-2750kg/h

|

Details Images

Application

Low-smoke halogen-free cable material/LOSF

halogen-free resistance fuel/HFFR

PVC cable material,

45% carbon black masterbatch,

60~85% filling masterbatch,

black /white masterbatch, etc.

HFFR PVC LOSF Cable granules

XLPE Cross-link granules

Hot Searches