Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MC

-

Voltage:

-

380V,415V,440V or Customized

-

Dimension(L*W*H):

-

26mx2.2mx2.4m

-

Power (kW):

-

80

-

Weight:

-

5.2 KG

-

Keywords:

-

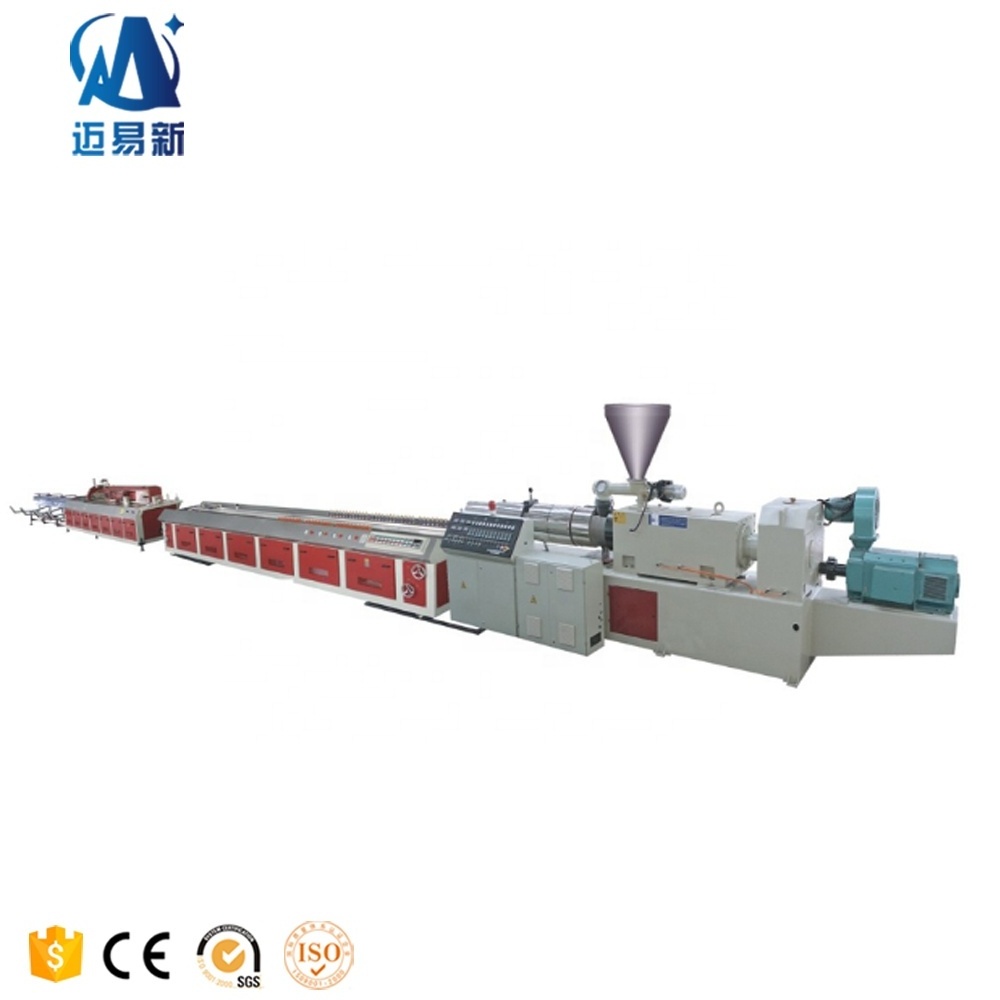

SJZ65 PVC Window Profile Production Making Machine Extrusion Line

-

Usage:

-

for making PVC profile,WPC plate,ceiling board,plate

-

Raw material:

-

PVC+Caco3+additive material

-

Extruder:

-

SJZ65/132 conical twin screw extruder

-

Frequency inverter brand:

-

ABB

-

Temperature controller brand:

-

Omron

-

Electric contactor brand:

-

Schneider

-

Motor brand:

-

Siemens

-

Automatic Grade:

-

Fully Automatic

-

Name:

-

SJZ65 PVC Window Profile Production Making Machine Extrusion Line

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

65/132

-

Screw Speed (rpm):

-

36 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MC

-

Voltage:

-

380V,415V,440V or Customized

-

Dimension(L*W*H):

-

26mx2.2mx2.4m

-

Power (kW):

-

80

-

Weight:

-

5.2 KG

-

Keywords:

-

SJZ65 PVC Window Profile Production Making Machine Extrusion Line

-

Usage:

-

for making PVC profile,WPC plate,ceiling board,plate

-

Raw material:

-

PVC+Caco3+additive material

-

Extruder:

-

SJZ65/132 conical twin screw extruder

-

Frequency inverter brand:

-

ABB

-

Temperature controller brand:

-

Omron

-

Electric contactor brand:

-

Schneider

-

Motor brand:

-

Siemens

-

Automatic Grade:

-

Fully Automatic

-

Name:

-

SJZ65 PVC Window Profile Production Making Machine Extrusion Line

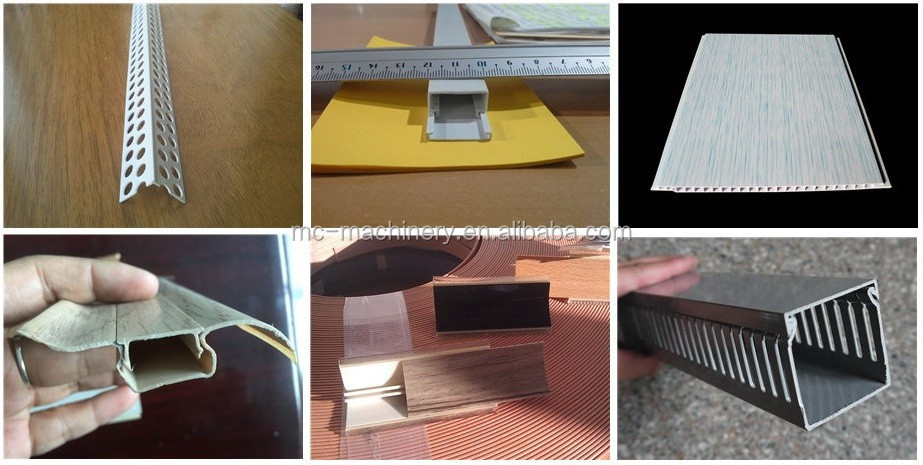

Product Application

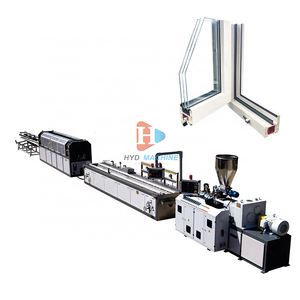

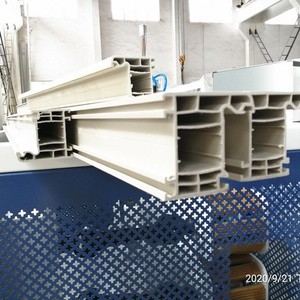

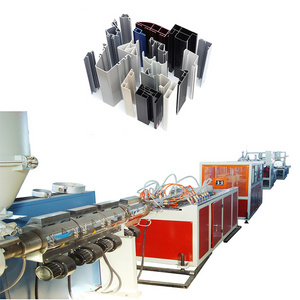

SJZ65 PVC Window Profile Production Making Machine Extrusion Line is mainly used for making PVC plastic profile with different section shape and height. the surface of PVC profile/panel can be treated by printing & coated with glossy oil, or by heat transfer printing, or by lamination, which can make good decoration effect for kitchen,toilet,balcony and so on.

Features of the Machine:

1)Extruder screw and barrel from Zhoushan,with vacuum degassing system, can get rid of the waste gas from the raw material which can ensure good quality of final granules.

2) Gearbox: From Jiangyin gearbox company,very famous brand in China,with nice outline, stable running, low noise and long service time.

3) Heating system: adopting cast aluminum heaters with stainless steel plate covers, wind fan cooling system, ensuring good features of cooling and heating, precision temperature controlling.

4) Driving system: adopting Siemens motor, using ABB inverter which provide stable torque output and various speed.

5) Vacuum calibrating and cooling Table: the tabley is made by #304 stainless steel, good strength and performance,long life time.

6) Traction machines:Rubber block traction belt,traction speed is adjustable by ABB frequency inverter.

7) Cutting machine: saw blade cutting,low noise,quick cutting performance,with dust collection device.

Main Machine Flow Chart

|

No

|

Machine Name

|

Quantity

|

|

1

|

Screw Loader for Mixer

|

|

|

2

|

SRL-Z serious High Speed Compound Mixing Unit

|

|

|

3

|

Screw Loader for Extruder

|

|

|

4

|

SJZ serious Conical Twin Screw Extruder

|

|

|

5

|

Mold head+Calibration forming mold

|

|

|

6

|

Vacuum Calibration Machine

|

|

|

7

|

Traction Machine

|

|

|

8

|

Cutting Machine

|

|

|

9

|

Stacking Table

|

|

Pre-Sales Service

* We given client the details technician offer.

* Professional advice for Inquiry and technical support.

* supply the details layout, installation instruction, technician support for the clients

* Free Machine testing support.

* View our Factory,sales manager accompany.

* 24 hours English support.

After-Sales Service

* We arrange engineer to install the machinery and training the workers for client abroad if clients required.

* We have 24 hours team to solve problems after sales.

* We have free spare parts with the right machine during warranty time.

* We supply whole machine lifetime spare parts for every customer with low cost after warranty time.

* We always up date the new technology to every customer.

2)We have CE ,ISO,BV,SGS certification

3)We take testing on every product before delivery.

4)Our quality supervision department oversees the whole process during manufacturing and machine testing before machine made

shippment.

2.What is the MOQ?

3.If you can make machine custom-made?

Marksim: Yes,we can make products special design according to customer's requirements.

4.What is the machine voltage?

Marksim: Normally 380V,50hz,3 phase.But we can change it according to customer's requirement, like 220V,240V,415V,440V,600V and so on.

5.What is this machine guarantee time?

Marksim: 1 year

6.When the machine can be deliveried?

7.We want to visiting your factory first before order,if it is avaliable?

8.If we finally buy your machine,you can send engineers to our country and help installation and training our workers?

Marksim: Yes,of course,if you needed,we will send engineer to your country to your factory to help installation and training your workers,but you have to bear our engineer's flight charge around,take responsibility of engineer's food and hotel during his visiting and pay salary USD100 per day for one person.

9.I’m a foreign customer,if the machine some part is broken one day,how can we get help from you?