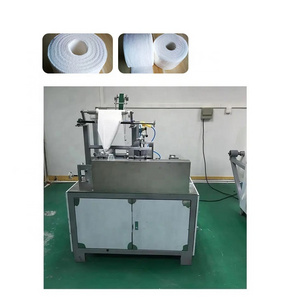

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

15KW

-

Dimension(L*W*H):

-

5820x2450x2040mm

-

Weight:

-

1650 kg

-

Warranty:

-

one year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

MOTOR:

-

SERVO MOTOR

-

Control system:

-

PLC

-

Good afterservice:

-

long term spare part supply

-

Machine type:

-

for 30-120pcs/pack

-

other services:

-

customization is available

-

information:

-

baby wet wipes packing machine

-

Folding type:

-

"N" or "Z", 12 lanes

-

After Warranty Service:

-

Video technical support

-

Certification:

-

ce

Quick Details

-

Production Capacity:

-

3600-4200pcs/min

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

DG

-

Voltage:

-

380v

-

Power:

-

15KW

-

Dimension(L*W*H):

-

5820x2450x2040mm

-

Weight:

-

1650 kg

-

Warranty:

-

one year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

MOTOR:

-

SERVO MOTOR

-

Control system:

-

PLC

-

Good afterservice:

-

long term spare part supply

-

Machine type:

-

for 30-120pcs/pack

-

other services:

-

customization is available

-

information:

-

baby wet wipes packing machine

-

Folding type:

-

"N" or "Z", 12 lanes

-

After Warranty Service:

-

Video technical support

-

Certification:

-

ce

Product Description

With air cylinder controlling system

Classic and simple folding units designed for pop-up and non pop-up version of wipes ( N folds)

Adopt adjustable online-spraying wetting system for tissue moistening (Flow meters and taps for regulation)

The tension unit is made of stainless steel roller with food-grade belts

Stacking & Counting Device

Adjustable folding uniformity, movement transfer by servo motor control,ensure stacking orderly

Specification

|

Suitable Material

|

Spunlace non-woven, hot rolling non-woven fabrics, Air-laid paper

|

|

Packing Film

|

OPP/PE, PET/PE ,PET/AL/PE

|

|

Machine Size

|

4260x2040x2450mm

|

|

Machine Weight

|

1050kg

|

|

Folding Way

|

"Z" "W" "C" folding

|

|

Speed

|

1800-2100 pcs/min

|

|

Product Type

|

30~120 pcs per pack non pop up wet wipes

|

|

Size of product (unfolded)

|

(110-200)X(170-220)(MM)(LxW) (Modifiable)

|

|

Size of product (folded)

|

(110-200)X(90-110)(MM)(LxW) (Modifiable)

|

Production Flow

Raw material loading → vertical-folding → tissue wetting → tissue cutting → tissue counting and stacking → tissue delivery

Technical Feature

1. Adopts Full servo drive and PLC control system for operation.2. Water tank with agitator.

3. Full servo design,with scientific design and compact structure, easy operation and maintenance.

4. Main electrical parts approved by CE or UL license, with safety door and E-stop and relative safety system.

5. Main mechanical parts made by CNC, main electric parts from Japan famous brand (Panasonic, Siemens,Mitsubishi, OMRON).

6. Human-machine interface, parameter setting is convenient and quick.

7. The transmission system is simple, the work is more reliable,and the maintenance is more convenient.

8. All control is realized by software, which is convenient for function adjustment and technical vitality, and never lags behind.

9. The parts in contact with liquid and fabric are made of stainless steel. All the processes are finished on the machine without manual labor involved, so the finished product could meet hygienic standard.

Finished Products

Technical Feature

1. Adopts Full servo drive and PLC control system for operation.2. Water tank with agitator.

3. Full servo design,with scientific design and compact structure, easy operation and maintenance.

4. Main electrical parts approved by CE or UL license, with safety door and E-stop and relative safety system.

5. Main mechanical parts made by CNC, main electric parts from Japan famous brand (Panasonic, Siemens,Mitsubishi, OMRON).

6. Human-machine interface, parameter setting is convenient and quick.

7. The transmission system is simple, the work is more reliable,and the maintenance is more convenient.

8. All control is realized by software, which is convenient for function adjustment and technical vitality, and never lags behind.

9. The parts in contact with liquid and fabric are made of stainless steel. All the processes are finished on the machine without manual labor involved, so the finished product could meet hygienic standard.

Finished Products

Hot Searches