- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Liquid Image

-

Voltage:

-

110-240 V

-

Power:

-

50 hz

-

Dimension(L*W*H):

-

42x31x26

-

Weight (KG):

-

4

-

Product Name:

-

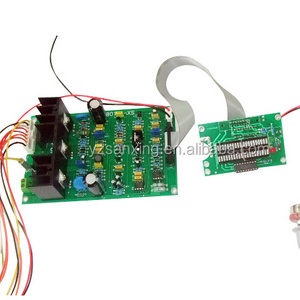

TEST electrostatic paint equipment Powder Coat Spray gun

-

Key Words:

-

MINI powder coating Machine

-

Input voltage::

-

120 -240VAC, 50/60Hz

-

Output voltage::

-

30/ 35/ 40/ 45 / 50 kv (adjustable.)

-

Air Pressure::

-

10 to 30psi

Quick Details

-

Machine Type:

-

powder coating spray gun machine, Painting Equipment, Pre-treatment Equipment, Coating Equipment

-

Marketing Type:

-

2024 new product

-

Core Components:

-

spray gun

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Liquid Image

-

Voltage:

-

110-240 V

-

Power:

-

50 hz

-

Dimension(L*W*H):

-

42x31x26

-

Weight (KG):

-

4

-

Product Name:

-

TEST electrostatic paint equipment Powder Coat Spray gun

-

Key Words:

-

MINI powder coating Machine

-

Input voltage::

-

120 -240VAC, 50/60Hz

-

Output voltage::

-

30/ 35/ 40/ 45 / 50 kv (adjustable.)

-

Air Pressure::

-

10 to 30psi

Specification

|

Name

|

Starter Powder Coating Spray Machine

|

|

Application

|

steel furniture, hardware, auto parts etc.

|

|

MOQ

|

1 Set

|

|

Input voltage:

|

120 -240VAC, 50/60Hz

|

|

Output voltage:

|

30/ 35/ 40/ 45 / 50 kv (adjustable.)

|

|

Air Pressure:

|

10 to 30psi

|

|

Control Box Fuse

|

0.5 amps

|

|

Certification:

|

CE

|

Techical Apply

What is Powder Coating?

Powder coating is a surface treatment used to protect metals and other materials against potentially harmful environmental factors. This coating is applied electrostatically as a free-flowing powder and cured under heat or UV light.

What Advantage Our Powder Coating Have?

Powder coatings are durable, attractive, scratch-resistant, long-lasting and environmentally responsible when compared to other finishes.

In which area powder coating be used?

Powder coating is widely used in all kinds of metal products, such as shelves, filing cabinets, agricultural machinery, steel furniture, road and bridge guardrail sound screens, security doors, aluminum profiles and black and white household appliances.

Physical Properties

:

|

Specific gravity:

|

1.4-1.7 (for color and gloss vary)

|

|

|

|

|||

|

Particle size distribution:

|

less than 100 microns (based on the special requirements of coating adjusted)

|

|

|

|

|||

|

Curing condition:

|

180°C (work piece temperature), 15-20 minutes. or 200°C (work piece temperature), 10 minutes

|

|

|

|

|||

|

Coverage

|

9-12 square meters per Kg at around 80 μm film thickness

|

|

|

|

|||

Technical Test-Quality Control

There are certain specific tests for powder and for the cured coating. We exercised extremely strict quality control during all stages of the manufacturing process.

|

Test Item

|

|

Test Methods

|

Test Results

|

|

|

Mechanical Behavior

|

Pencil Hardness

|

GB/T 6739-1996

|

H-2H

|

|

|

|

Bending

|

GB/T 9286-1998

|

O Class

|

|

|

|

Grid Test 1mm

|

GB/T 6742-1986

|

≤2mm

|

|

|

|

Impulse Test

|

GB/T 1732-1993

|

≥50kg.cm

|

|

|

|

Cupping Test

|

GB/T 9753-1988

|

≥7mm

|

|

|

Corrosion Resistance

|

Heat Resistance

|

GB/T 1771-1991

|

>500 hours

|

|

|

|

Salt Spray

|

GB/T 1740-1979

|

>1000 hours

|

|

|

Heat resistance

|

|

110℃/24 hours (white sample)

|

Excellent Gloss Retention and Color Retention △E ≤0.6

|

|

Storage Stability

Store in ventilated, dry, clean room, temperature < 25℃

Relative humidity 50-65%

Away from direct sunlight, fire, heat

For best performance, use within 6 months

Packing & Delivery

Powder Coating powders are well sealed in Thick plastic bags, then packed in

standard

carton. Net weight 20kg or 25kg, and ensure no-leaking.

Hot Searches