- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless Steel

-

Screen area:

-

2.5m2

-

Inlet pulp consistency:

-

1-4%

-

Screen hole size:

-

1.6-3.5mm

-

Screen slot size:

-

0.10-0.55mm

-

Screen hole capacity:

-

300-600tpd

-

Screen slot capacity:

-

250-400tpd

-

Usage:

-

Paper mill

-

Experience:

-

39 years

Quick Details

-

Production Capacity:

-

250-600tpd

-

Place of Origin:

-

Henan, China

-

Name:

-

ZNS2.5 pressure screen

-

Material:

-

Stainless Steel

-

Screen area:

-

2.5m2

-

Inlet pulp consistency:

-

1-4%

-

Screen hole size:

-

1.6-3.5mm

-

Screen slot size:

-

0.10-0.55mm

-

Screen hole capacity:

-

300-600tpd

-

Screen slot capacity:

-

250-400tpd

-

Usage:

-

Paper mill

-

Experience:

-

39 years

small paper pulp molding machine, screening machine for making pulp

Paper machine pressure screen brief introduction

Leizhan ZNS series paper machine pressure screen automatic waste paper recycling machine is used as a screening equipment to screen out rejects in stock preparation.

Paper machine pressure screen main specification

|

Type |

ZNS0.3 |

ZNS0.6 |

ZNS0.9 |

ZNS1.2 |

ZNS1.5 |

ZNS2 |

ZNS2.5 |

ZNS3 |

ZNS4 |

ZNS6 |

|

Screen area(m²) |

0.3 |

0.6 |

0.9 |

1.2 |

1.5 |

2 |

2.5 |

3 |

4 |

6 |

|

Screen hole size(mm) |

φ1.6-φ3.5 |

|||||||||

|

Screen seam size(mm) |

0.10-0.55 |

|||||||||

|

Production capacity( t/d) |

50-80 |

90-160 |

135-250 |

180-320 |

200-380 |

260-500 |

300-600 |

400-700 |

500-1000 |

800-1500 |

|

30-50 |

60-100 |

90-150 |

120-190 |

140-230 |

200-300 |

250-400 |

300-450 |

350-730 |

500-1100 |

|

|

Inlet pulp consistency ( % ) |

1.5-4 |

|||||||||

|

Motor power ( Kw) |

22-55 |

30-75 |

37-90 |

45-110 |

55-132 |

75-160 |

90-200 |

90-220 |

132-280 |

250-400 |

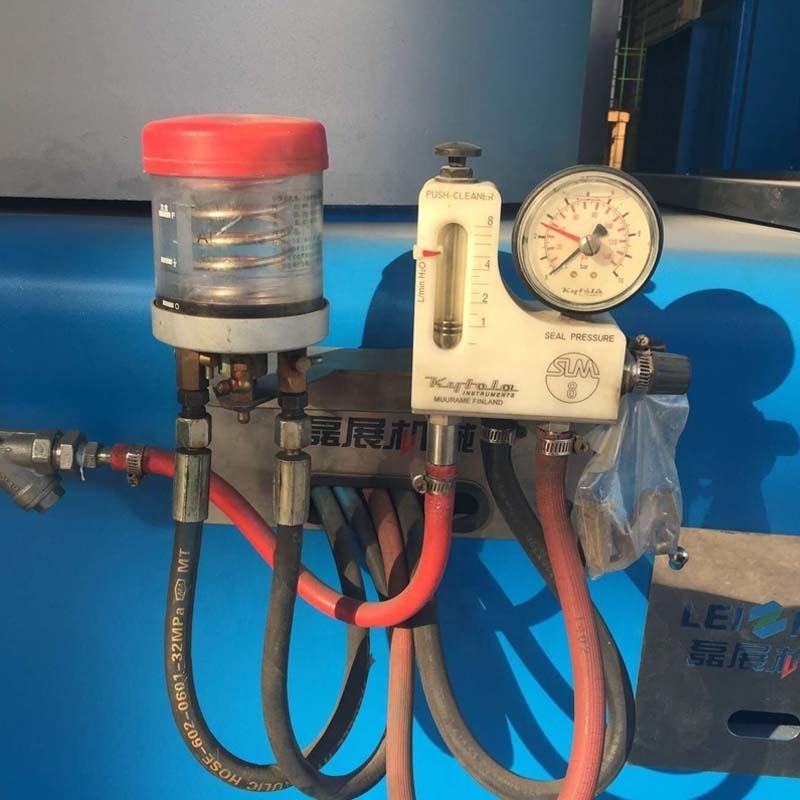

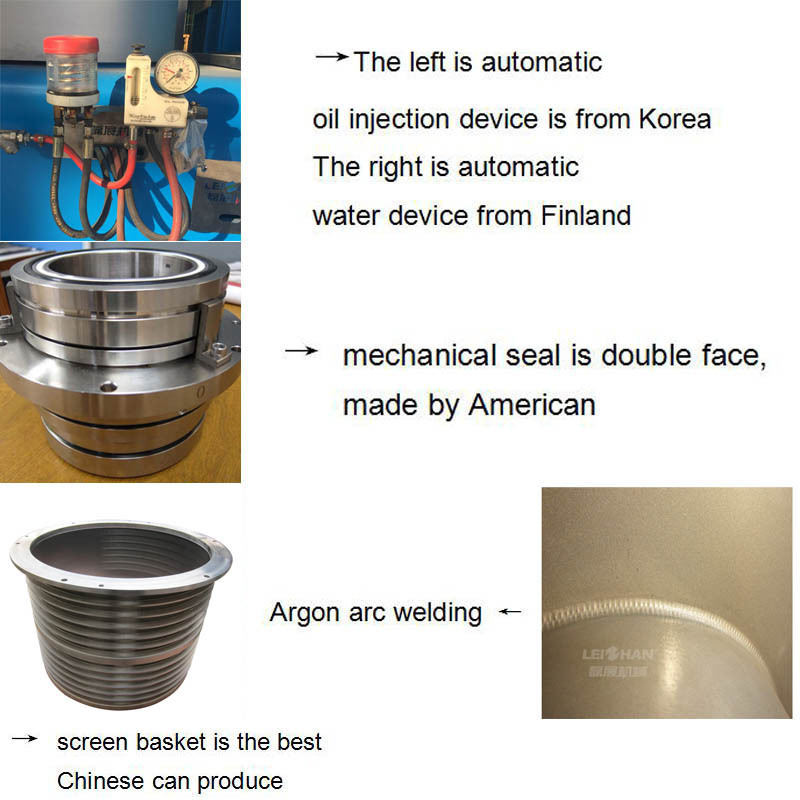

Paper machine pressure screen advantages

Paper machine pressure screen working site

Leizhan service

1.Pre-sales Service

- Proposing the most suitable scheme and equipment for our clients.

- Designing and fabricating targeted products according to the special requirements of clients.

- Training periodically high qualified service technician.

2.After-sales Service

- Assisting our clients for foundation construction of equipment.

- Dispatching engineers to install and debug equipment.

- Training the first-line operators on site.

- Regularly visit clients to solve production problems.

Paper machine pressure screen packaging and delivery

1.Export packing.(Wooden case, carbon cast and pallet).