- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

ASTM G65 High abrasion resistant wear plate parts for mining machinery

-

Model Number:

-

WD1200, WD1500

-

Technique:

-

Hardfacing, open arc welding, submerged arc welding

-

Surface Treatment:

-

hardfacing, cladding, coated, Chromium carbide overlay coated

-

Application:

-

Mining, Steel, Cement, Power, Port, Glass, Coal, Sugar, etc.

-

Special use:

-

Wear Resistant Steel

-

Base metal material:

-

Q235B, Q345B, A36, S235JR

-

Microstructure:

-

Carbide (Cr7C3)volume fraction above 50%

-

Chemical composition:

-

C: 3-5%, Cr: 25-40%, Mn: 1-3%, Si:1-3%, Fe: balance

-

Flatness tolerance:

-

±3mm/m

Quick Details

-

Weight (KG):

-

30

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

WODON

-

Product name:

-

ASTM G65 High abrasion resistant wear plate parts for mining machinery

-

Model Number:

-

WD1200, WD1500

-

Technique:

-

Hardfacing, open arc welding, submerged arc welding

-

Surface Treatment:

-

hardfacing, cladding, coated, Chromium carbide overlay coated

-

Application:

-

Mining, Steel, Cement, Power, Port, Glass, Coal, Sugar, etc.

-

Special use:

-

Wear Resistant Steel

-

Base metal material:

-

Q235B, Q345B, A36, S235JR

-

Microstructure:

-

Carbide (Cr7C3)volume fraction above 50%

-

Chemical composition:

-

C: 3-5%, Cr: 25-40%, Mn: 1-3%, Si:1-3%, Fe: balance

-

Flatness tolerance:

-

±3mm/m

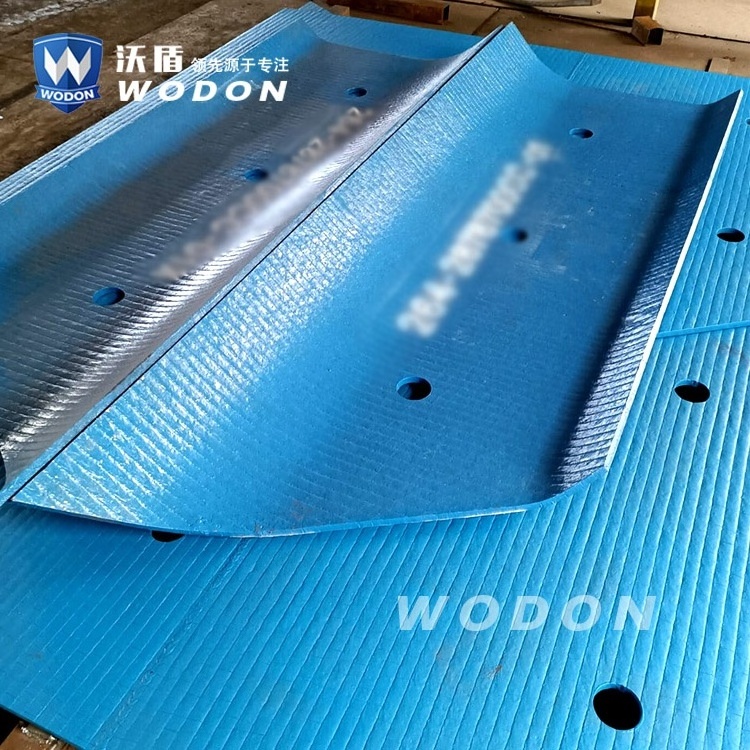

ASTM G65 High abrasion resistant wear plate parts for mining machinery

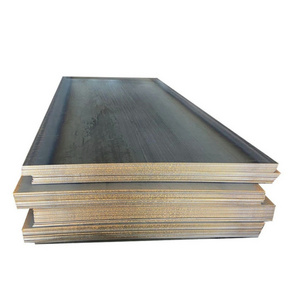

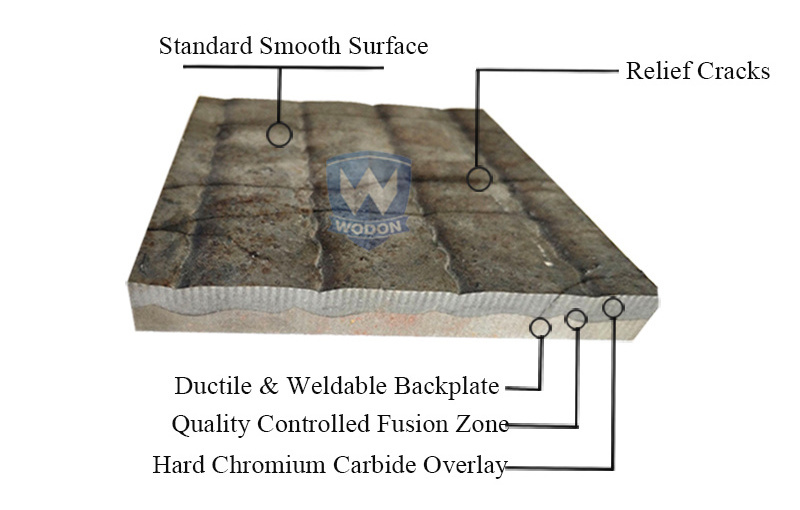

Chromium carbide overlay Wear plate

we can make:

* Thickness: 3+3mm, 4+4mm, 5+5mm,6+6mm....20+20mm, 40+30mm etc

* Sheet size: 1400*3400mm, 1400*3500, 2100*3500mm etc

* Chemical Composition: C, Cr, Mn, Si, Fe etc

* Hardness: HRC 58-65

* Welding: Submerged arc & Open arc

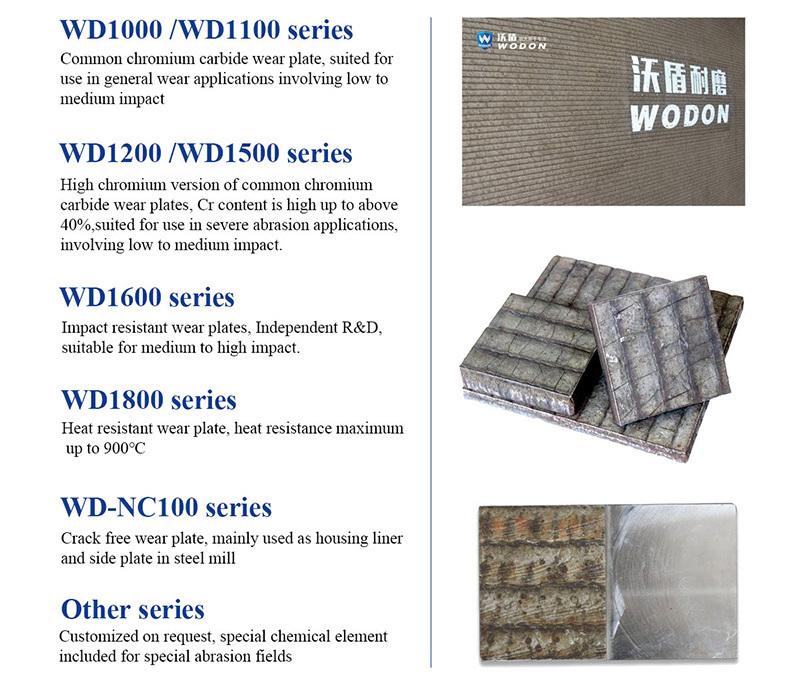

Chromium Carbide Overlay Wear Plates

| Model | Characteristics | Hardness | Chemical Composition (%) | Operating Temperature | ||||||

| (HRC) | C | Cr | Mn | Si | Mo+Nb | Ni+V+W | Fe | |||

| WD-1000 | Common chromium carbide wear plate, suited for use in general wear applications involving low to medium impact | 58-65 | 3.0-5.0 | 17.0-27.0 | 1.0-3.0 | 1.0-3.0 | / | / | Bal. | <400℃ |

| WD-1100 | ||||||||||

| WD-1200 | High chromium carbide wear plates, Cr content is high up to above 40%,suited for use in severe abrasion applications, involving low to medium impact. | 58-65 | 3.0-6.0 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | / | / | Bal. | <400℃ |

| WD-1500 | ||||||||||

| WD-1600 | Impact resistant wear plates, Independent R&D, suitable for medium to high impact. | 58-65 | 3.5-6.5 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | * | / | Bal. | <600℃ |

| WD-1800 | Heat resistant wear plate, heat resistance maximum up to 900℃ | 58-65 | 4.0-7.0 | 25.0-40.0 | / | / | * | * | Bal. | <900℃ |

| WD-NC100 | Crack free wear plate, mainly used as housing liner and side plate in steel mill | 50-55 | ||||||||

| Other series | Customized on request, special chemical element included for special abrasion fields | / | ||||||||

| Sheet size: 1400*3400mm 1400*3000mm 1500*3000mm 1400*3500mm 2000*3000mm 2100*3500mm Other on request | ||||||||||

| Base metal material: Q235, Q345 and so on. | ||||||||||

| Overlayer thickness: 3-50mm | ||||||||||

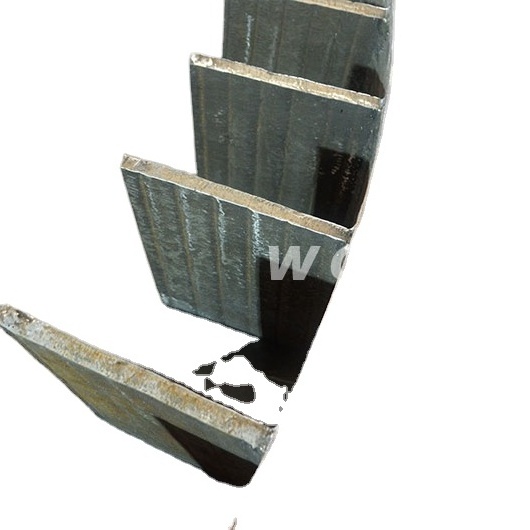

Picture of Submerged arc welding plate:

1. The overlay chemical composition is the key

The main ingredients of Wodon plates are C(%) :3.0-5.0 and Cr(%):25-40. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

Performance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: Choosing same dimension specimens for different materials and wear plate producers, and put them under the same wearing working conditions in our testing equipment.

45 minutes for each specimen

Results: The test results show that the life span of Wodon wear plate is 2.5 times higher than domestic wear plates and 1.5 times than imported ones.

2. Chromium carbide microstructure

The wear resistance of wear plate depends mostly on the hardness, shape, size, amount and distribution of the chromium carbide hard particles.

As you can check on the picture, the carbide (Cr7C3) volume fraction on the microstructure is above 50%.

3. Bonding strength between the overlay and base plate.

The overlay and base plate are very well bonding. The overlay will penetrate into base plate about 0.8mm-1.8mm, reaching up to 350Mpa in our tests.

d

ustry.