- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.6 mm ~ 1.5 mm

-

Place of Origin:

-

China

-

Brand Name:

-

WADJAY

-

Voltage:

-

Customized

-

Weight:

-

3500 kg

-

Name:

-

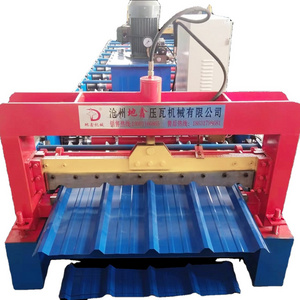

Roll Forming Machine

-

Color of Machine:

-

Beige Or As Your Request

-

Certification:

-

CE/ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.6 mm ~ 1.5 mm

-

Place of Origin:

-

China

-

Brand Name:

-

WADJAY

-

Voltage:

-

Customized

-

Weight:

-

3500 kg

-

Name:

-

Roll Forming Machine

-

Color of Machine:

-

Beige Or As Your Request

-

Certification:

-

CE/ISO

Product Description

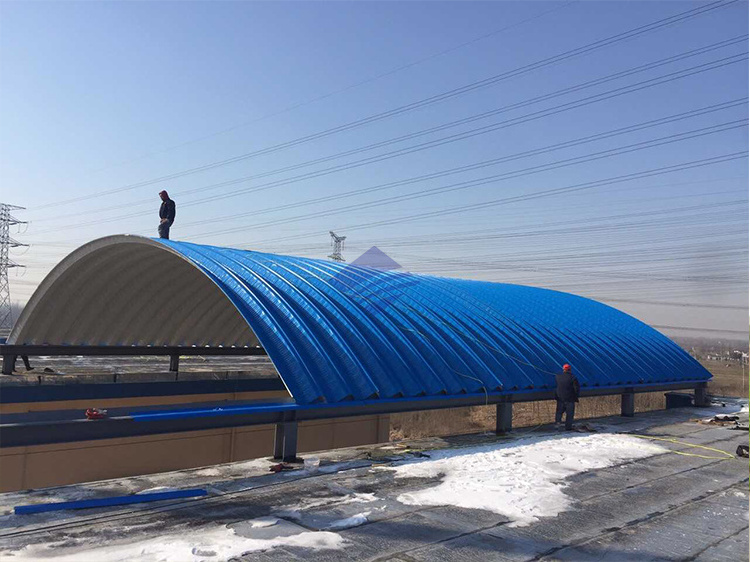

- Why use K-SPAN System?

K-Span system mobile roll forming machines are capable of constructing arch buildings and roofs on site, with spans ranging from as narrow as 4m to as wide as 40m. There is no limitation on the length of the building or roof that can be produced.

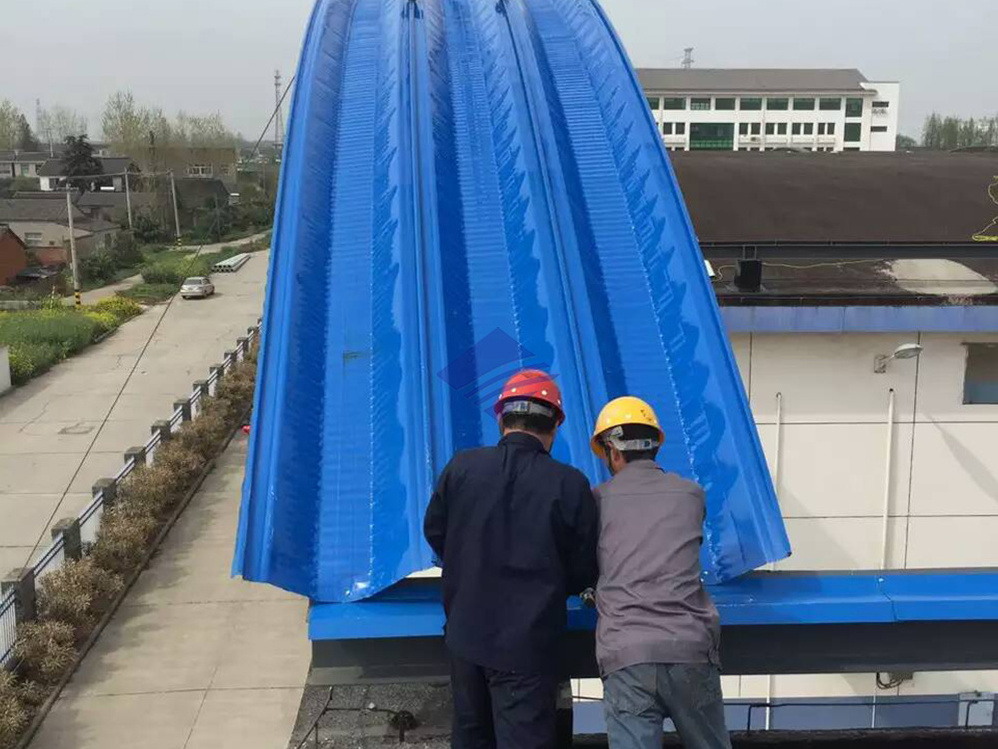

K-Span system arch roofs can be installed on masonry brick, concrete or steel structures, eliminating the need for a conventional roof support structure.

K-Span system arch buildings and roofs can be adapted to fit existing infrastructure or be considered as a standalone solution for new projects.

K-Span system arch buildings and roofs can be extended at any time after completion offering clients the flexibility to expand infrastructure as the need develops.

K-Span system arch roofs can be installed on masonry brick, concrete or steel structures, eliminating the need for a conventional roof support structure.

K-Span system arch buildings and roofs can be adapted to fit existing infrastructure or be considered as a standalone solution for new projects.

K-Span system arch buildings and roofs can be extended at any time after completion offering clients the flexibility to expand infrastructure as the need develops.

- Effect of Relative Project

:

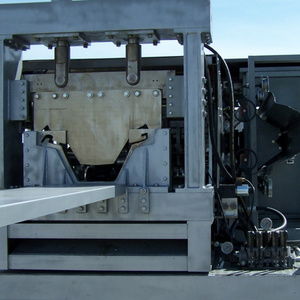

- Working Process of Arch Roof Machine :

Decoiler → Roll Forming Device

→

Hydraulic Cutting Device

→

Curving Device

- Profile Drawing

of Arch Roof Machine:

- Details display description of Arch Roof Machine :

Protable Arch Roof Forming Machine

Hydraulic Cutting system (More stable & powerful)

PLC Automatic Control

Cutting Blade material: Real Cr12 (Solid Cr12)

Cutting Blade material: Real Cr12 (Solid Cr12)

All machines will be painted 3 times. One of them is to use high-quality rust-proof printing oil to prevent the machine from rusting and maintain a longer service life.

Control system: Famous Brand PLC SIEMENS (Automatic and Manual Changeable control system) Construction costs calculator software is set up in the control table

Rollers: 15 roller stations, more than 25 working steps

Rollers materials: Hard chrome coated 45# steel (reducing the roller wear)

The surface is polished (stop scratching the steel sheets)

High temperature quenched

Decoilers:

We improved the design of the Decoiler. It is easier to adjusting and faster to loading a steel coil

4 tires Air braking system and shock absorption sheet

Specification

- Specifications for Arch Roof Machine

|

Drive System

|

Electric

|

|

Power Device

|

30kw Diesel Generator

|

|

Electric Standard

|

380v, 50hz, 3 phase

|

|

Total Power

|

18.5kw

|

|

Forming Power

|

7.5kw

|

|

Cutting Power

|

4.0kw

|

|

Bending Power

|

4.0kw

|

|

Conical Power

|

3.0kw

|

|

Step of Rollers

|

13 Steps

|

|

Material of Rollers

|

45# Steel, quenched HRC 58-62

|

|

Material of Shafts

|

45# Steel, quenched HRC 58-62

|

|

Material of Cutting Blade

|

Cr12MoV Steel

|

|

Type of Cutting System

|

Hydraulic

|

|

Material of Bending Leaves

|

Stainless Steel

|

|

Forming Speed

|

15m/min

|

|

Bending Speed

|

13m/min

|

|

Seaming Speed

|

6-8m/min

|

|

Control System

|

PLC (Omron)

|

|

Uncoiler Capacity

|

About 6000kg

|

Packing & Delivery

- Shipping and Installation

Reliable packaging in accordance with international shipping standards with the assurance of Arch roof roll forming machine.

Popular Products

Hot Searches