- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

could be customized

-

Dimension(L*W*H):

-

2800x1150x1730

-

Weight:

-

3800 kg

-

Marketing Type:

-

New Product 2022

-

product name:

-

poultry feed pellet mill machine

-

color:

-

white and blue, or as your requsted

-

output:

-

10t/h

-

feeder power:

-

1.5

-

conditioner power:

-

5.5

-

Ring die inner diameter:

-

400

-

granular size:

-

2-10

-

structure:

-

compact

-

service life:

-

long

-

energy consumption:

-

low

Quick Details

-

Max. Capacity:

-

10 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RICHI

-

Voltage:

-

could be customized

-

Dimension(L*W*H):

-

2800x1150x1730

-

Weight:

-

3800 kg

-

Marketing Type:

-

New Product 2022

-

product name:

-

poultry feed pellet mill machine

-

color:

-

white and blue, or as your requsted

-

output:

-

10t/h

-

feeder power:

-

1.5

-

conditioner power:

-

5.5

-

Ring die inner diameter:

-

400

-

granular size:

-

2-10

-

structure:

-

compact

-

service life:

-

long

-

energy consumption:

-

low

Application of Poultry Feed Making Machine

This SZLH 350 Poultry Feed Making Machine is mainly suitable for the production of animal feed pellets for livestock, poultry, rumination, aquaculture and so on. The Capacity is 5-8T/H , And it is a good choice for the farm owner and those who plans to step into the poultry feed making industry.

The main transmission adopts high-precision gear rotation, and the efficiency is increased by about 15% compared with the belt transmission type, and the ring mold adopts the quick-release type hoop.

High-quality imported bearings and oil seals are used in the transmission part of the whole machine to ensure efficient, stable and low noise.

|

Different Types Of Poultry Feed Making Machine

|

|

|

|

|

|

|

||||||

|

Model

|

Main Power

|

Feeder Power

|

Conditioner Power

|

Dia.of Ring Die

|

Pellet Size

|

Capacity

|

||||||

|

SZLH250

|

22KW

|

1.1KW

|

1.5KW

|

250mm

|

φ1.0-12.0mm

|

1-2T/H

|

||||||

|

SZLH320

|

37KW

|

1.5KW

|

2.2KW

|

320mm

|

φ1.0-12.0mm

|

3-5T/H

|

||||||

|

SZLH350

|

55KW

|

1.5KW

|

3.0KW

|

350mm

|

φ1.0-12.0mm

|

5-8T/H

|

||||||

|

SZLH420

|

110KW

|

1.5KW

|

7.5KW

|

420mm

|

φ1.0-12.0mm

|

8-12T/H

|

||||||

|

SZLH508

|

132/160KW

|

2.2KW

|

11KW

|

508mm

|

φ1.0-12.0mm

|

12-18T/H

|

||||||

|

SZLH-558

|

180/200KW

|

2.2KW

|

11KW

|

558mm

|

φ1.0-12.0mm

|

15-25T/H

|

||||||

|

SZLH-678

|

220/250KW

|

2.2KW

|

11KW

|

678mm

|

φ1.0-12.0mm

|

20-30T/H

|

||||||

|

SZLH-768

|

250/280KW

|

2.2KW

|

11KW

|

768mm

|

φ1.0-12.0mm

|

25-40T/H

|

||||||

|

SZLH-858

|

315/355KW

|

2.2KW

|

15KW

|

858mm

|

φ1.0-12.0mm

|

28-45T/H

|

||||||

Main Features Of Poultry Feed Making Machine

1. The main transmission adopts high-precision gear rotation, and the efficiency is increased by about 15% compared with the belt transmission type, and the ring mold adopts the quick-release type hoop .

2. High-quality imported bearings and oil seals are used in the transmission part of the whole machine to ensure efficient, stable and low noise.

3. The international advanced level compensation serpentine spring coupling has the characteristics of novel structure, compact, safe, low failure and so on.

4. Strengthen the working strength of the main working parts from the materials, heat treatment and other processes to meet the granulation requirements of biomass particles.

5. There are a number of innovative designs on the ring die, mainly to improve the problems of the ring die to prevent cracking, increase in output and increase in total output.

6. Configured with overload protection device to increase the service life of equipment.

7. The feed auger, conditioner, door cover and ring die are made of stainless steel to avoid contamination of raw materials due to equipment corrosion and longer service life.

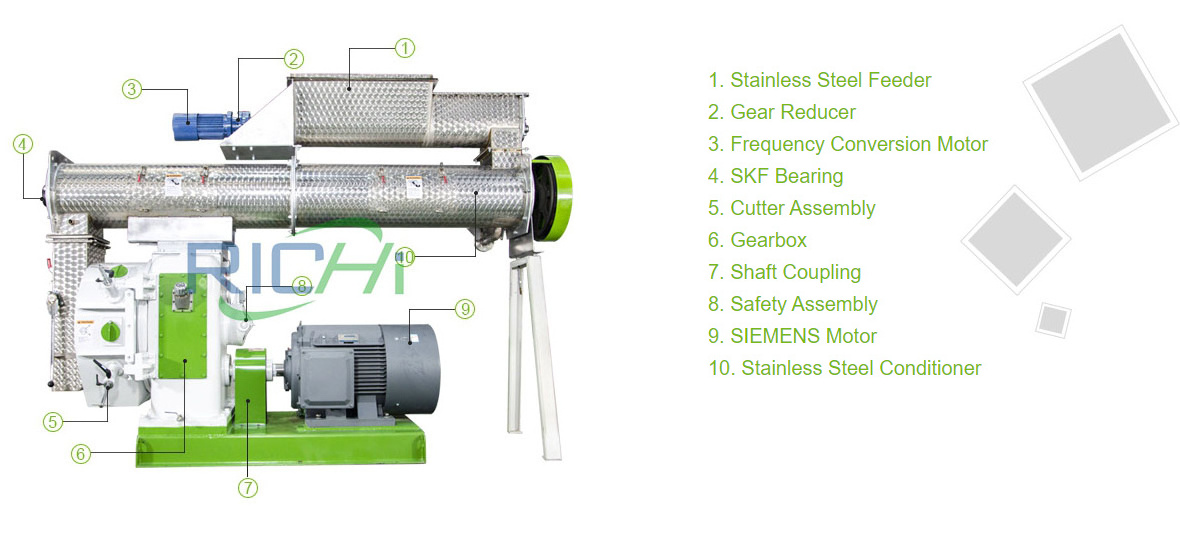

Frequency Control Feeder

This model adopts the advanced variable frequency motor feeding,with overload protection devices and machines outside the nesting organization;

All material is s tainless steel.

Stainless Steel Conditioner

The function of conditioner :It will be connected with boiler, the steam will be supply by the steam boiler.raw materials of feed and steam will be mixed in the conditioner.

Siemens Motor And SKF Bearing

Imported hig-quality spindle bearings SKF bearings.

Stainless Steel Ring Die

The ring die mould is the heart part of pellet mill machine, and it's one the most easy wearing spare parts as well.

This model is available in a variety of aperture between Φ1.5-Φ12mm ring mold, the user can arbitrarily chosen according to different needs.

The Gear Box

This model of feed pellet machine uses one-motor straight gear drive system, with the ideal gear ratio,drive torque, stable transmission, high output, low noise, easy operation and maintenance;

The Pelletizing Chamber

The pelletizing chamber include the roller assembly, stainless steel ring die, cutter assembly, feed chute,Manuel feed inlet, etc.

Main Features of Cattle Poultry Feed Plant

1) Simple structure in linear type ,easy in installation and operation.

2) Adopting advanced world famous brand Siemens motor for the main machines, such as the hammer mill, mixer and pellet mill.

3) The dimension of this Chicken Feed Pellet Making Line is about 9*5*12m(Length*width*height).

4) Running this Chicken Feed Pellet Making Line needs about 3to 4 persons. And their responsibilities are as follows:

1 or 2 persons working at the feeding section;

1 person takes care of the pellet machine and watches the control panel

1 person works at the packing section;

5) This Cattle Poultry Feed Plant can make different kind of animal feed pellets, not only the chicken feed, but also the cattle feed, sheep feed and other kind of pellet feed or powder feed.

pellet machine , pellet mill , pellet making machine , feed machine, feed pellet machine, feed pellet mill , feed pellet making machine , feed making machine , animal feed pellet machine , poultry feed pellet machine , animal feed pellet mill , animal feed pellet making machine , animal feed making machine , chicken feed pellet machine,feed mixer , feed hammer mill