- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product

-

Weight (KG):

-

3000 KG, 3000 KG

-

Power (kW):

-

40kw, 40KW

-

Product name:

-

Vacuum Membrane Press Machine

-

Table size:

-

2500*1300mm(inside diameter)

-

Overall dimensions:

-

10800*1800*1700mm

-

Maximum machining height:

-

60mm(including backing plate)

-

Hydraulic pressure:

-

About 10mpa

-

Consumption rated working press:

-

Member pressure<-0.1mpa

-

Brand:

-

Rensolin

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rensolin

-

Machine Type:

-

Board vacuum membrane press, CNC Dovetail Tenoner

-

Marketing Type:

-

Hot Product

-

Weight (KG):

-

3000 KG, 3000 KG

-

Power (kW):

-

40kw, 40KW

-

Product name:

-

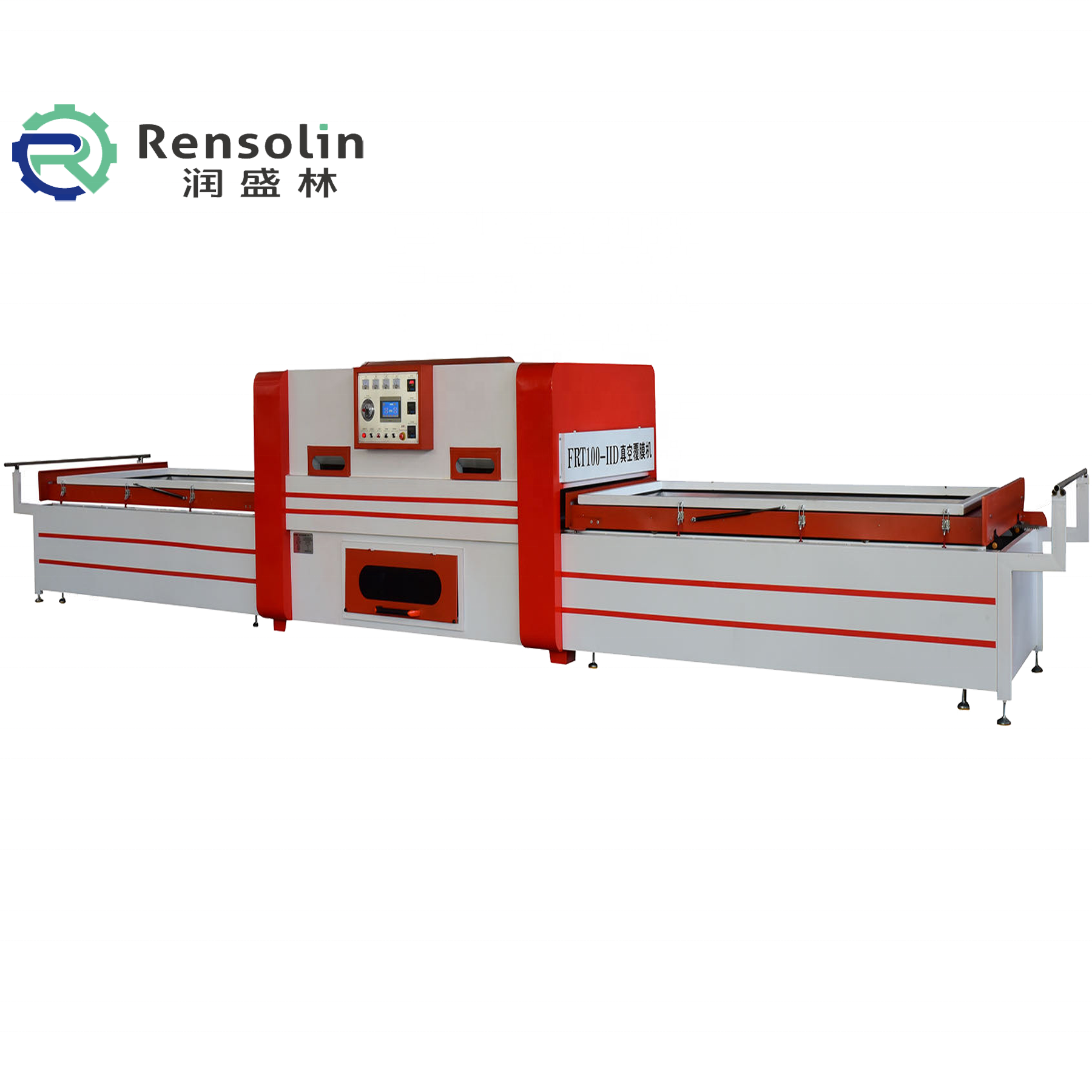

Vacuum Membrane Press Machine

-

Table size:

-

2500*1300mm(inside diameter)

-

Overall dimensions:

-

10800*1800*1700mm

-

Maximum machining height:

-

60mm(including backing plate)

-

Hydraulic pressure:

-

About 10mpa

-

Consumption rated working press:

-

Member pressure<-0.1mpa

-

Brand:

-

Rensolin

Products Description

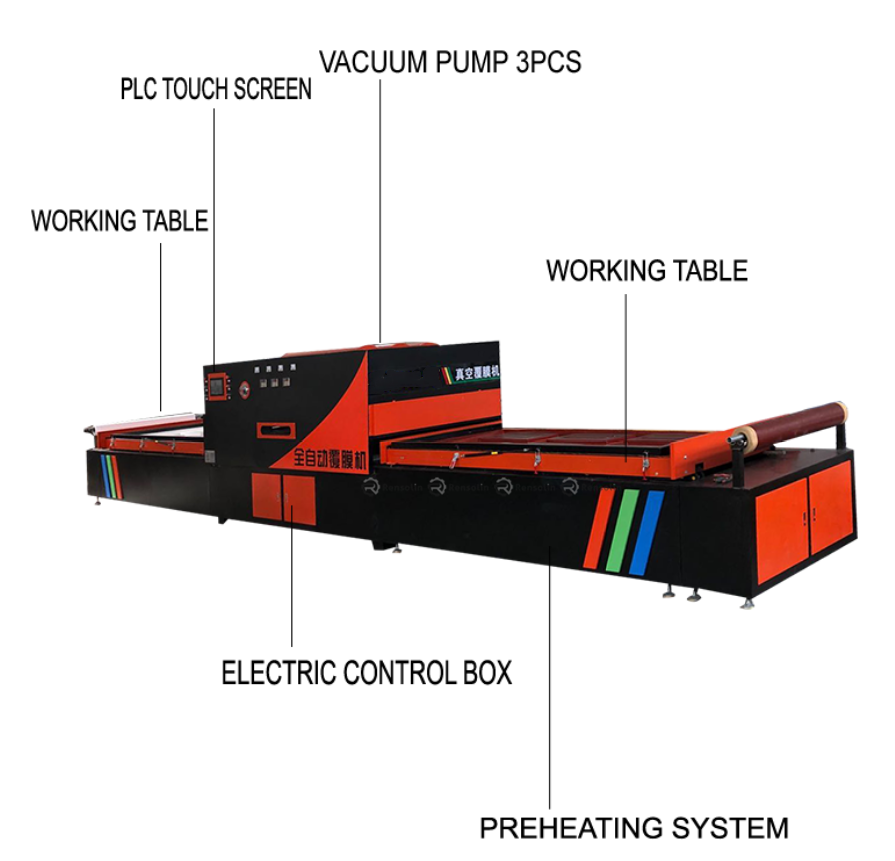

Automatic vacuum laminating machine

Keyword

:

Preheating System/Working Table; Vacuum Pump 3pcs; PLC Touch Screen

Product Paramenters

|

Name

|

Vacuum Membrane Press Machine

|

|

|

|

|||

|

Maximum machining height

|

60mm(including backing plate)

|

|

|

|

|||

|

Operation interface

|

With a single liquid crystal display

|

|

|

|

|||

|

Hydraulic pressure

|

About 10mpa

|

|

|

|

|||

|

The total energy army

|

40kw

|

|

|

|

|||

|

Actual power

|

7kw

|

|

|

|

|||

|

Consumption rated working press

|

Member pressure<-0.1mpa

|

|

|

|

|||

|

Table size

|

2500*1300mm(inside diameter)

|

|

|

|

|||

|

Weight

|

3T

|

|

|

|

|||

|

Overall dimensions

|

10800*1800*1700mm

|

|

|

|

|||

Details display

1. CNC operation panel

The 10-inch control large screen, using digital display automatic control technology, simple

operation, high degree of automation, stable energy absorption, high yield

operation, high degree of automation, stable energy absorption, high yield

2. Blister workbench

Special treatment of worktable, imitation deformation, no deformation after long time heating

3. Distribution box

The electric control system adopts high temperature resistance and high insulation materials, which is safe and reliable in operation

4.140 vacuum pump 3 large gas storage tanks

It has strong adsorption capacity and fast plastic absorption. It adopts Sino-foreign

joint venture X0140 rotary vane vacuum pump, which can work continuously and be air-cooled.

joint venture X0140 rotary vane vacuum pump, which can work continuously and be air-cooled.

5. Constant temperature heating

The constant temperature heating design is used to make the plate film uniformly heated, effectively avoiding the peeling and wrinkling phenomenon caused by uneven heating of the plate

High-sensitivity vacuum gauge, accurate display, sensitive pressure change display, low failure rate.

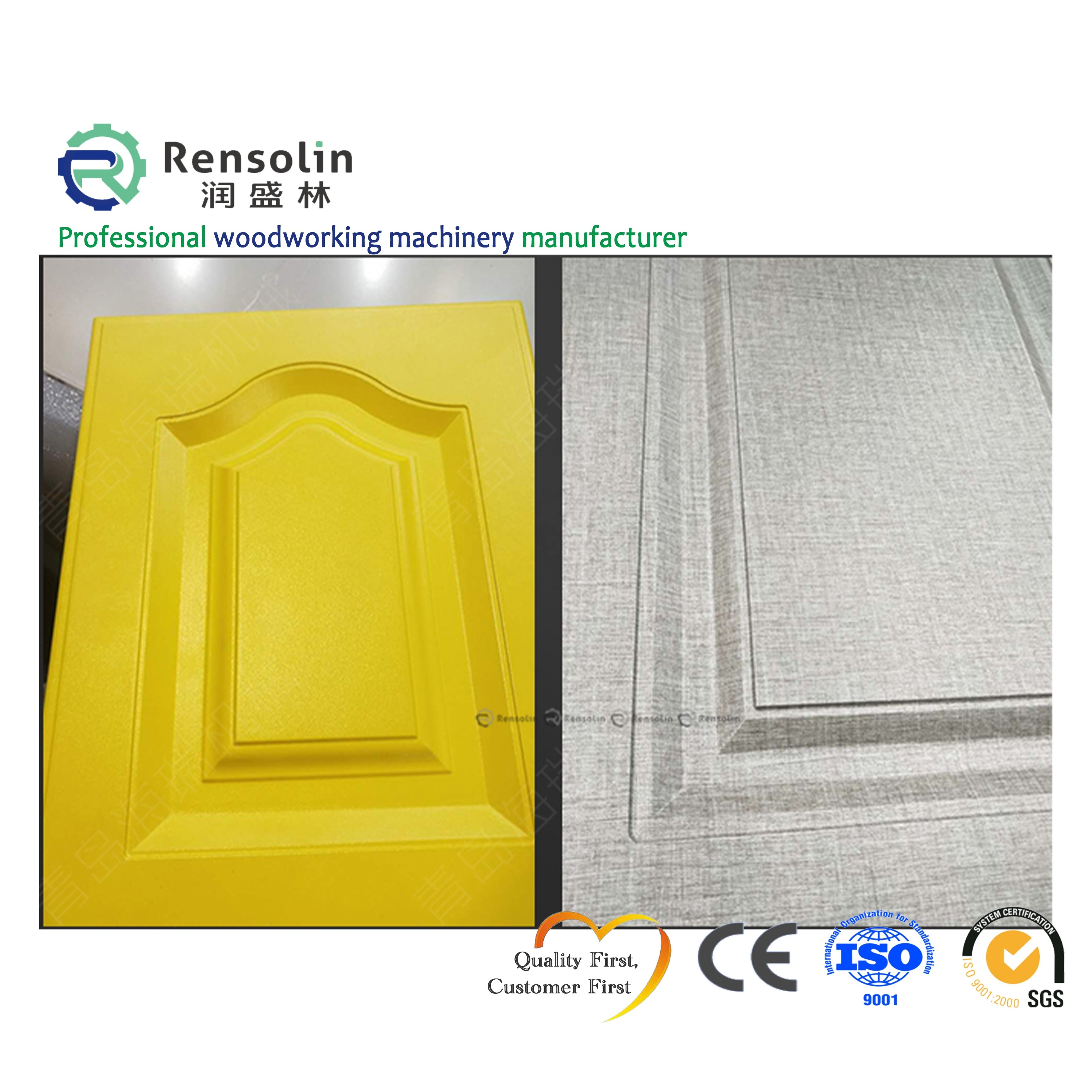

Products Effect Display

Service

PRE-SALE SERVICES:

1. Introduce and Provide detailed consultation of the machine.

2. Strict quality control system, warranty period: 2 years.

3. Provide custom- -made service, offering good suggest and design idea to customer.

4. Welcome to visit our factory.

SERVICES DURING SALES:

1. Fast delivery and 100% QC Inspection before shipment.

2. Install and debug the machine well in our factory.

3. Provide safety package and shipping to clients.

AFTER-SALE SERVICES:

1. Carefully train frst-line operators' operation knowledge.

2. Engineers available to service machinery overseas timely.

3. Our sales team and senior engineer are ready for service for you in every 7x24h.

FAQ

Q1: How to install?

A1: We adjusted machines well before we deliver. When customers receive them, you can work with them directly.

For sliding table saw you just need install sliding table on machine body by 4 bolts.

For sliding table saw you just need install sliding table on machine body by 4 bolts.

Q2: How to ensure the safety?

A2: There have the overload and over heat protection, it ensure working people safety.

Q3: How long the table saw machine can be used?

Q3: How long the table saw machine can be used?

A3: It depends how you use your table saw, if use it in good maintenance, at least8-10 years.

Q4: What is the Delivery time?

Q4: What is the Delivery time?

A4. Our delivery time is around 3-15 days. Before the machine arrive at the port, the shippingcompany will call you.

Q5: Where is your company located?

Q5: Where is your company located?

A5: We are Chinese company. Our city is in Qingdao. It is the biggest seaport in the north ofChina.

Q6: Are there any requirements for the dealer?

Q6: Are there any requirements for the dealer?

A6: There is no special conditions to be our dealer. You buy from us and sell to your customers. We introduce customers to you.

Related Products

Dears friends, Send me an inquiry, I will give you unexpected discount surprises,Don't hesitate, we are the quality supplier you

are want looking for !!!

Hot Searches