3. building materials

Building construction is one of the most important areas of application for PU rigid foam. In the United States and other countries, the construction of PU hard foam accounts for about half of the total consumption of hard foam, which is more than double the amount of hard foam used in refrigerators and freezers. Many countries in the world have clear regulations on the energy consumption of building construction, which promotes the application of rigid foam in building construction. The annual consumption of polyurethane foam in construction in the United States is about 300,000 tons, accounting for 65% of the building foam market (the rest is polystyrene and phenolic foam), accounting for about 50% of the total PU foam.

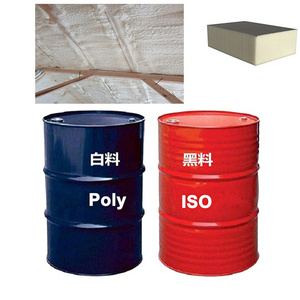

In China, hard foam has been widely applied to the insulation and waterproofing of residential and office building roofs, thermal insulation of walls, cold storage, grain storage and other insulation materials. Spray hard foam for the roof, plus a protective layer, which has the dual effect of heat insulation and waterproof.

The metal surface rigid polyurethane sandwich panel is made of flame-retardant rigid polyurethane foam (two different formulations of PU and PIR), and the color coated steel sheet is used as the surface material, and continuously formed by PU or PIR foaming. And, also known as composite sheet. It combines light weight, high strength, heat insulation, waterproof and decoration. It is a multi-functional new building material that is easy to produce, construct and install.

At present, domestic metal surface rigid polyurethane sandwich panels are widely used in industrial plants, warehouses, stadiums, residential buildings, villas, movable board houses and combined cold storages, etc., for roofing and wall panels. Because of its light weight, heat insulation, waterproof, decorative and other characteristics, and convenient transportation (installation), the construction progress is fast, which is very popular among designers, construction and developers.

The PU hard foam is filled in the hollow brick, and can be made into a hard foam filled hollow brick, which has better heat preservation effect. It can also be made into PU rigid foam concrete. The density of this concrete block is about 200kg/m3, the compressive strength is 0.59~0.78MPa, and the thermal conductivity is about 64mW/(m·K), which can be made into large-sized building components.

PU rigid foam sheets can be made into a variety of folding mobile houses, which are used as temporary temporary rooms. For example, if the surface of a 10mm thick PU rigid foam is covered with polyethylene, it can be made into a folding house, or a PU hard foam can be used to make a full PU hard foam spherical temporary house.

Water conservancy facilities such as concrete dams need to adopt thermal insulation measures during cold winter construction, and PU hard foam can be sprayed on the new concrete surface as insulation layer. In the severe cold area, polyurethane insulation board can be used as the anti-freezing material for channel lining, which reduces the damage of the channel rigid lining material by frost heave and ensures the stability of the lining and the safe use of the channel.