- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FL8021

-

Product name:

-

3 Ways Zinc alloy Valve Garden Water tap Splitter Connectors Adapter

-

Certificate:

-

ISO9001:2015

-

work pressure:

-

50-110 PSI

-

application:

-

water hose split

-

other application:

-

washing machine water in/out

-

others:

-

3 ways valve shut-off

Quick Details

-

Material:

-

Metal

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OEM

-

Model Number:

-

FL8021

-

Product name:

-

3 Ways Zinc alloy Valve Garden Water tap Splitter Connectors Adapter

-

Certificate:

-

ISO9001:2015

-

work pressure:

-

50-110 PSI

-

application:

-

water hose split

-

other application:

-

washing machine water in/out

-

others:

-

3 ways valve shut-off

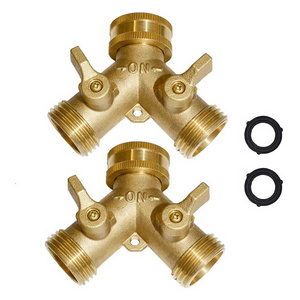

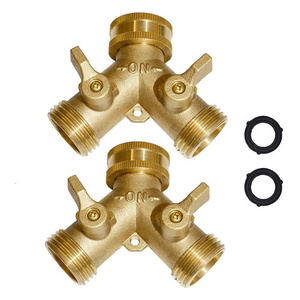

3 Ways Zinc alloy Metallic Y Valve Garden Water tap Splitter Connectors Adapter

Features:

1) FL8021: zinc y shape splitter with shut-off switch valve

2) Material: Zinc, chromate plating

3) Size: 3/4"M*3/4"M*3/4F GPT

4) Type: Y connector with valve

Applicability:

1) Garden hose splitter

2) Washer hose coupling

We also can provde brass Y shape connector with/out valve

And we can produce components according to your request accurately.

We take charge of the whole production processes from product design, mold creation, producing, packaging, ...etc to ensure our ustomers to have quality productsof all standards.like ANSI ,DIN, BSP ,JIS.PF,PTF etc.

Our creative R&D Department keeps developing new moulds, finishes to meet customers' high standard requirement. We also welcome customer own designs for OEM and ODM cooperation. For more information, please contact us to get our prompt service.

Your prompt response will be highly appreciated!

Cixi Weiyue Metal product Co., Ltd. Formely known asCixi Fule Flooding Equipment Co., Ltd.

set up in the year of 2001, is one of the manufacturing factory main provide customization metal die-casting, forging, cold or warm form pressing, stamping and precision CNC lathe machining service, We have a complete in-house manufacturing system-from products design, making, testing to parts mass-production.

Our factory have been approved by ISO9001:2015 supervisory system, all our workshop and products are manufactured under it. Main processes workshop include precision forging and stamping workshop, cold/ward forming press workshop, CNC lathe machining workshop, and inspection and packing workshop.

|

OEM/ODM Service |

According to customers prints, drawings, specifications or samples |

|

Production range |

auto parts, industrial metal parts, machine fitting and hardware parts |

|

Available materials |

steel alloy, brass, aluminum/zinc alloy, iron and stainless steel |

|

Manufacturing process |

· Hot forging + machining · Warm/cold compressing + machining · Sheet stamping + machining · Bar stock + cnc machining · Braiding (stainless steel wire) |

|

Available production processes |

Annealing, heat treatment, sand-blasting, surface plating, polish, QC testing and packing |

|

Available finishes |

fine polished, chrome, zinc, nickel plating, anodize with all kinds of customized colors, etc. |

|

Target customer |

Direct manufacturers, EAU purchase amount from $0.2 million to 2 million. |

|

Delivery time |

2-6 weeks for samples, 4-8 weeks for mass-production delivery |

|

OUR TEAM

|

||

|

Department |

Number of employees |

Years of work in this field |

|

General Manager |

1 |

16 |

|

Vice-general Manager |

1 |

12 |

|

Finance Dept. |

3 |

5-10 |

|

Purchase Dept. |

2 |

5-10 |

|

Technology Dept. |

3 |

8-16 |

|

Sales Dept. |

3 |

8-12 |

|

QC Dept. |

6 |

3-12 |

|

Production Dept |

52-62 |

1-12 |

1. Where is your location?

We are located in Ningbo City of China and are closed to Ningbo port It takes 2 hours by car.

2. Are you trading company or manufacturer?

.

We are a manufacturer.

3.

Will my drawing be safe after you get it?

Yes. We will not release your design to the third party unless with your permission.

4. How long does it take to receive samples?

a) Made from bar stock within 2 weeks.

b) Made by dies usually 4-8 weeks.

5. How to deal with the parts received when they are found to be in poor quality?

Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non-conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time. The resulting transportation costs are borne by our company.

6. Why you limited the customer EAU purchase amount?

We are the factory 100% produce the parts by ourselves to control the best quality, it cause the capacity limited.