- Product Details

- {{item.text}}

Quick Details

-

Row Distance(mm):

-

600 - 700 mm

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

maxizm

-

Dimension(L*W*H):

-

7800x2290x4190mm

-

Weight:

-

8800 KG

-

Product name:

-

Combine Rice Wheat Harvester

-

After-sales Service Provided:

-

Spare Parts

-

Local Service Location:

-

Malaysia

-

Name:

-

Two Rows Silage Harvester Machine

-

Function:

-

Combined Grain Harvester

-

After Warranty Service:

-

Spare Parts Support

-

Keywords:

-

Harvesting Equipment

-

Used for:

-

Paddy Rice Wheat Harvesting

-

Color:

-

Customer Requirement

-

Power:

-

103KW (140 Hp)

Quick Details

-

Number of Rows:

-

3

-

Working Width(mm):

-

2035 mm

-

Tractor Power(HP):

-

180 - 210 HP

-

Row Distance(mm):

-

600 - 700 mm

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

maxizm

-

Dimension(L*W*H):

-

7800x2290x4190mm

-

Weight:

-

8800 KG

-

Product name:

-

Combine Rice Wheat Harvester

-

After-sales Service Provided:

-

Spare Parts

-

Local Service Location:

-

Malaysia

-

Name:

-

Two Rows Silage Harvester Machine

-

Function:

-

Combined Grain Harvester

-

After Warranty Service:

-

Spare Parts Support

-

Keywords:

-

Harvesting Equipment

-

Used for:

-

Paddy Rice Wheat Harvesting

-

Color:

-

Customer Requirement

-

Power:

-

103KW (140 Hp)

Agricultural Machinery 210HP AC60C Cut-off Wheel Sugarcane Harvester for sale

Contact way

Products Description

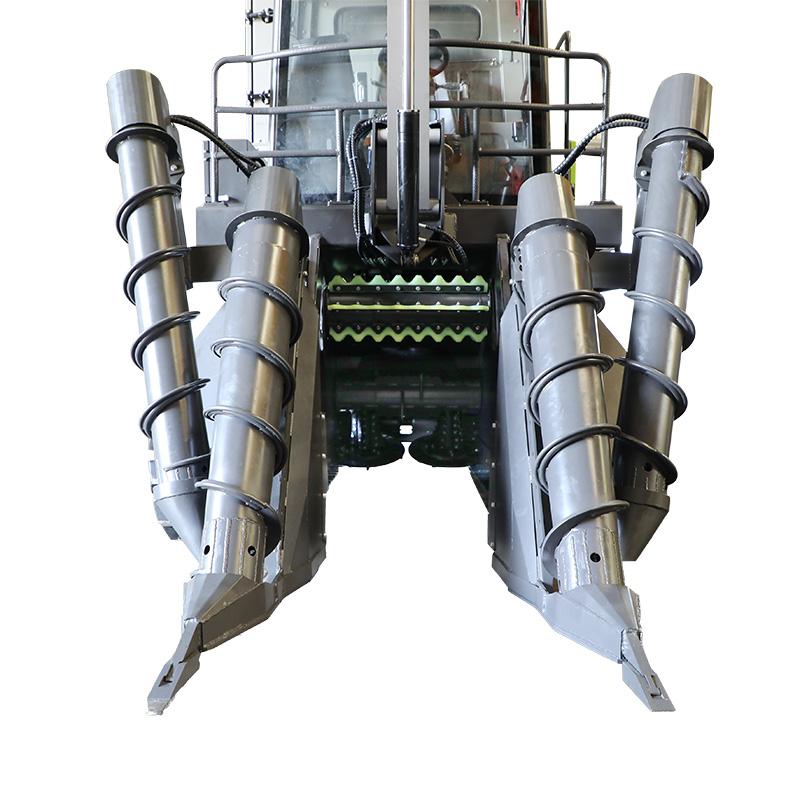

* Suitable for working on slope below 10°and field over 1.2m row spacing;

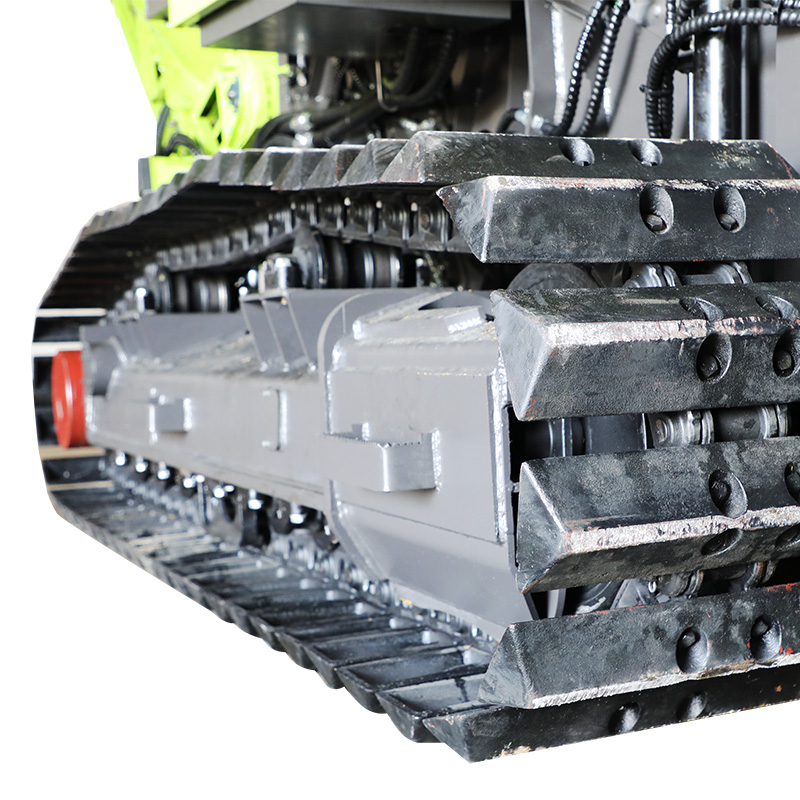

* Wheel drive, driving power is 20% larger than other counterparts, fast for transferring cane field.

* New generation of conveying arm, bending support quick disassembly, steel wire rope pull belt structure, stability greatly

improved;

* Equipped with 210HP Cummins six cylinder engine, strong power, low fuel consumption, reliable performance;

* Conveying channel adopts automatic variable-diameter conveying technology, which can automatically adjust the harvesting height

according to the feeding quantity to adapt to different sugarcane diameters and feeding volume, which prevents crushing of

sugarcane and blocking of conveying path;

* Extractor is designed as a barrel structure, in which an axial flow blower is installed and driven by hydraulic motor. Strong

upflow is formed such that cane impurities can be easily cleaned;

* Topper system including dividing disc and cutter disc, Topper’s drums gather and cut the tops efficiently, cut off top in one

piece and spread out the tops away from the unharvesting rows, which avoids tops second time harvesting and decreases impurity

rate;

* Bidirectional spiral rollers, which are independent of each other when it is undulating on the left and right and making

sugarcane splitting. They move up and down, back and forth respectively to adapt to the sugarcane with different lodging postures

according to the actual status of sugarcane in the field.

* Wheel drive, driving power is 20% larger than other counterparts, fast for transferring cane field.

* New generation of conveying arm, bending support quick disassembly, steel wire rope pull belt structure, stability greatly

improved;

* Equipped with 210HP Cummins six cylinder engine, strong power, low fuel consumption, reliable performance;

* Conveying channel adopts automatic variable-diameter conveying technology, which can automatically adjust the harvesting height

according to the feeding quantity to adapt to different sugarcane diameters and feeding volume, which prevents crushing of

sugarcane and blocking of conveying path;

* Extractor is designed as a barrel structure, in which an axial flow blower is installed and driven by hydraulic motor. Strong

upflow is formed such that cane impurities can be easily cleaned;

* Topper system including dividing disc and cutter disc, Topper’s drums gather and cut the tops efficiently, cut off top in one

piece and spread out the tops away from the unharvesting rows, which avoids tops second time harvesting and decreases impurity

rate;

* Bidirectional spiral rollers, which are independent of each other when it is undulating on the left and right and making

sugarcane splitting. They move up and down, back and forth respectively to adapt to the sugarcane with different lodging postures

according to the actual status of sugarcane in the field.

Performance Parameters

|

Mode

|

|

Unit

|

AC60C

|

|

|

Harvester |

Size(L×W×H)

|

mm

|

7800×2290×4190(min)

12800×6100×4880(max) |

|

|

|

Weight

|

kg

|

8800

|

|

|

Engine |

Engine brand

|

/

|

Cummins QSB7

|

|

|

|

Engine type

|

/

|

In-line 6 cylinder

|

|

|

|

Displacement

|

L

|

6.87

|

|

|

|

Power

|

kW

|

140(Max 169)

|

|

|

|

Rotation speed

|

r/min

|

2050

|

|

|

|

Fuel capacity

|

L

|

200

|

|

|

Driving |

Front track

|

mm

|

1580

|

|

|

|

Rear track

|

mm

|

1510

|

|

|

|

Driving speed

|

km/h

|

0~18

|

|

|

|

Ground clearance

|

mm

|

265

|

|

|

Adaptability |

Suitable ridge spacing

|

mm

|

≥1200

|

|

|

|

Suitable ridge height

|

mm

|

0~200

|

|

|

|

Suitable slope

|

%

|

≤10

|

|

|

Performance |

Feeding capacity

|

kg/s

|

6

|

|

|

|

Net work hour productivity

|

t/h

|

>15

|

|

|

|

Loss rate

|

%

|

≤7

|

|

|

|

Impurity rate

|

%

|

≤8

|

|

|

|

Sugarcane acceptability

|

%

|

≥90

|

|

|

Others

|

Hydraulic oil capacity

|

L

|

180

|

|

Details Images

Packing &Shipping

Hot Searches