A full range of pre-and after-sale technical support services to help customers improve product value. Continued after-sales service will lift the customer's worries in using our toolings. For each of our tools and blades, we will provide one year warranty!

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TR14-00730

-

Material:

-

HSS,SKD11,SKH51

-

Design software:

-

PROE,UG

-

Name:

-

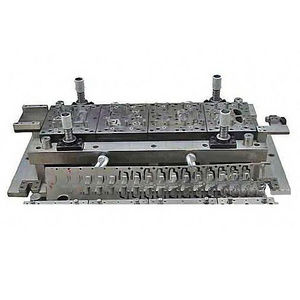

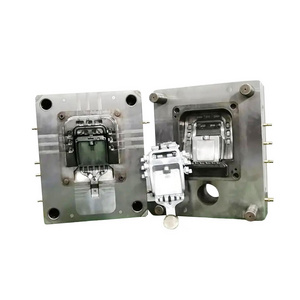

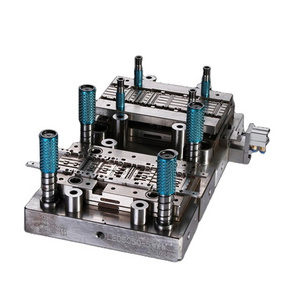

metal stamping die for power press

-

Mould life:

-

700000-800000shots

-

Type:

-

punching

-

Cavity:

-

Single

-

Runner:

-

Cold Runner

-

Certification:

-

ISO9001:2000

-

Application:

-

Household Product Mold

-

Surface treatment:

-

punching mold for aluminum foil container

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Tenroy

-

Model Number:

-

TR14-00730

-

Material:

-

HSS,SKD11,SKH51

-

Design software:

-

PROE,UG

-

Name:

-

metal stamping die for power press

-

Mould life:

-

700000-800000shots

-

Type:

-

punching

-

Cavity:

-

Single

-

Runner:

-

Cold Runner

-

Certification:

-

ISO9001:2000

-

Application:

-

Household Product Mold

-

Surface treatment:

-

punching mold for aluminum foil container

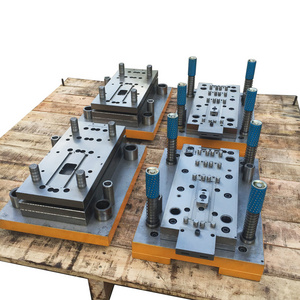

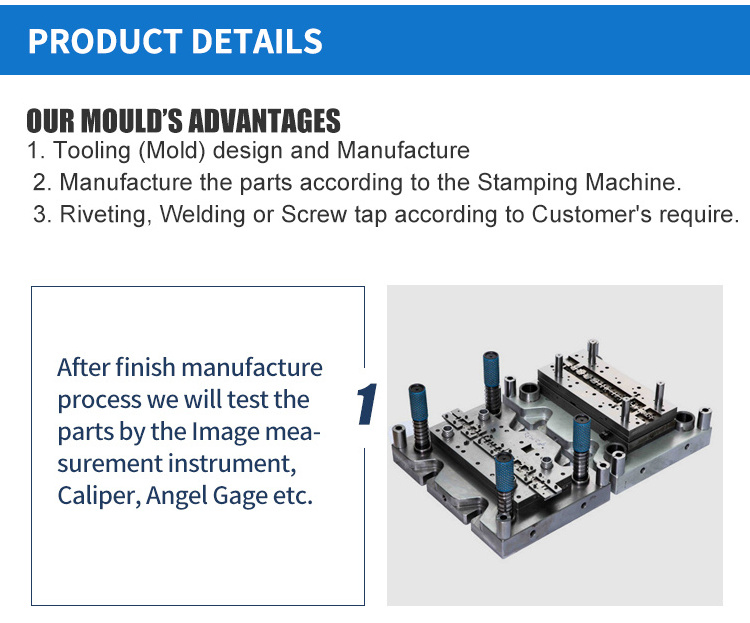

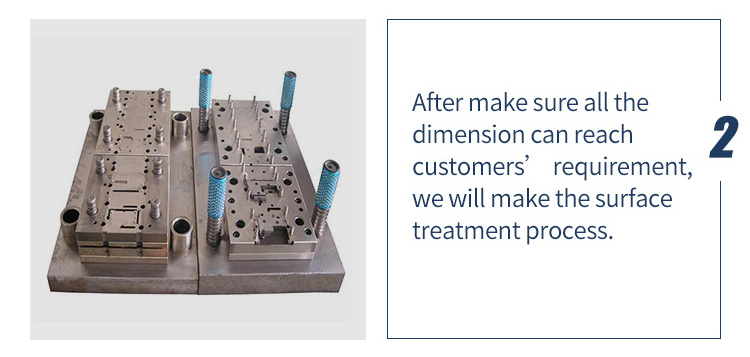

Our company is mainly engaged in sheet metal mold manufacturing and mechanical equipment machining. We have first-class technical personnel with rich work experience. Quality, service and price are the guarantee of our survival. Our mold manufacturing including: metal stamping molds, plastic alloy molds, stretch spinning molds, silicone rubber molds, PVC drop molds, high voltage molds, hot press molding molds, bronzing packaging molds, ultrasonic molds, tea brick embossing molds, etc. Our mechanical processing including: CNC computer engraving, copper and aluminum heat sink processing, relief processing, jig fixtures, mechanical automation accessories. Excellent advanced machinery and superb skills can create more wealth for you! More advantages about us 1. Tooling (Mold) design and Manufacture 2. Manufacture the parts according to the Stamping Machine. 3. Riveting, Welding or Screw tap according to Customer's require. 4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper, Angel Gage etc. 5. After make sure all the dimension can reach customers’ requirement, we will make the surface treatment process. 6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts which we sell is 100% qualified. 7. After finish testing we will pack the parts by Vacuum Package Machine.

|

|

Typical

|

Feasible

|

|

Shapes:

|

Flat

Thin-walled: Cylindrical

Thin-walled: Cubic

|

Thin-walled: Complex

|

|

Part Size:

|

Area: Up to 10 mm²

Weight: 0.5g-200KG

|

|

|

Material:

|

Metals

Alloy Steel

Carbon Steel

Stainless Steel

Aluminum

Copper

|

Lead

Magnesium

Nickel

Tin

Titanium

Zinc

|

|

Surface finish -Ra:

|

3.2 - 12.5 μmm

|

1.6 - 25 μmm

|

|

Tolerance:

|

± 0.1 mm

|

± 0.1 mm

|

|

Max wall thickness:

|

2 - 15 mm

|

1 - 25 mm

|

|

Advantages:

|

1.Can form complex shapes

2.Many material options

3.High production rate

4.Low labor cost

5.Short lead time possible

|

|

|

Disadvantages:

|

Limited to constant part thickness

Part may require several operations and machines

Large amount of scrap

|

|

|

Applications:

|

Brackets, panels, cans, utensils

|

|

Professional R & D Team

Tenroy has its own R & D team formed with 5 professional technicians, providing customers with mould design and selection, mould usage problem solution, mould maintenance and repair knowledge.

Quality Assurance

We adopt imported high quality tool steel. Each of our tools and blade will be tested before shipment. And their stable quality with long working life will be your best choice.

Lightning Delivery

Mass production of standard parts, smart stock! The lead time for standard type is 3-5 working days. And for special shape tools and blades, lead time is around 10-15 working days.

Packing Details: pack with carton box, 1set/small box, many sets/big strong carton box or wooden case.

Delivery Details: 3-5 working days

1. Anti rust oil before packing

2. Suitable carton size

3. Shock bubble film

4. Professional placement

5. Professional shock

6. Complete package

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team

Best Material

For press brake tools adopt 42CrMo and advanced processing technology. For punch press tools, we produce it with SKH-51 which can make the tools more durable and wear-resistant. For shearing blades & various industrial cutters , they are made from a special analysis of high carbon, high chrome tool steel.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the tools are standard. or it is 15-20 days if the tools is special forming shape.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: