- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LUTONG

-

Voltage:

-

380v/ 220v

-

Dimension(L*W*H):

-

20*2*1.8m

-

Power (kW):

-

80

-

Weight:

-

5000 KG

-

Automatic Grade:

-

automatic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

used for:

-

rope, twine

-

Power(W):

-

80kw

-

Raw material:

-

PP PE

-

Product Type:

-

Yarn

-

Capacity:

-

60-80kgs/h

-

Processing Type:

-

Extruding Equipment

-

skype:

-

cai610223

-

tel:

-

0086-15318645420

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

80 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LUTONG

-

Voltage:

-

380v/ 220v

-

Dimension(L*W*H):

-

20*2*1.8m

-

Power (kW):

-

80

-

Weight:

-

5000 KG

-

Automatic Grade:

-

automatic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

used for:

-

rope, twine

-

Power(W):

-

80kw

-

Raw material:

-

PP PE

-

Product Type:

-

Yarn

-

Capacity:

-

60-80kgs/h

-

Processing Type:

-

Extruding Equipment

-

skype:

-

cai610223

-

tel:

-

0086-15318645420

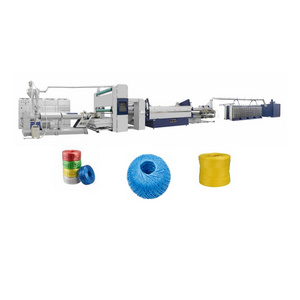

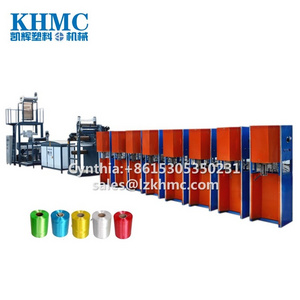

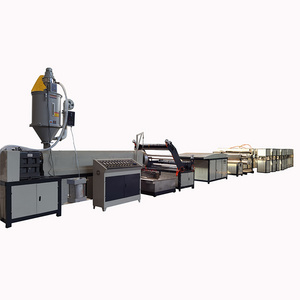

pp/plastic packing raffia baler twine making machine

Usage:

This set of machine is a professional yarn drawing line, which is mainly used for producing PP, HDPE net yarn, and also can be used for processing other plastic yarns via corresponding adjustment.

Characters:

This line consists of extruder, the first stretching device, heating extension board, needle roller, the second stretching device and coiling machine. The matching devices for production process are complete, so it can continuously finish the whole procedures from putting material to coil yarn onto bobbins...

According to different technological requirements , set and automatically control the heating temperature of screw cylinder and die head. The temperature can be adjusted according to different kinds of materials.

Adopts rotating needle roller, which can split the stretched yarns into net shape in order to make the yarns soft during next procedure of making ropes.

Technical specifications:

|

Model |

ND-55 |

ND-65 |

ND-75 |

ND-80 |

ND-90 |

|

Screw material |

38 # CrMoALA |

38 # CrMoALA |

38 # CrMoALA |

38 # CrMoALA |

38 # CrMoALA |

|

Screw dia. |

55mm |

65mm |

75mm |

80mm |

90mm |

|

L/D |

30:1 |

30:1 |

30:1 |

30:1 |

30:1 |

|

Rotate speed |

30-70 r/min |

30-70 r/min |

30-70 r/min |

30-70 r/min |

30-70 r/min |

|

Motor power |

15kw |

18.5kw |

22kw |

32kw |

40kw |

|

Heating power |

10-15kw |

15-20kw |

25-35kw |

30-40kw |

35-50kw |

|

Output |

40-50kg/h |

50-60kg/h |

50-80kg/h |

60-90kg/h |

70-100kg/h |

machine details:

components:

1. extruder with die head, electric box, co ld water container

2. the first stretching device

3. heating board

4. needle roller (optional)

5. the second stretching device

6. winder ( three types available)

production precedure:

1. virgin/recycled pp, new HDPE, or mixed are avaible.

2. wide film is extruded by extruder, and cut to many tapes by cutter.

3. tapes are heated on heating board.

4. after strectching, yarns are winded on bobbins.

finished products:

1. flat split film and net split film can be made.

2. 4500D-90000D yarn can be made.

3. the finished yarn can be make baler twine in spool or ball, or twisted to rope.

workshop show: