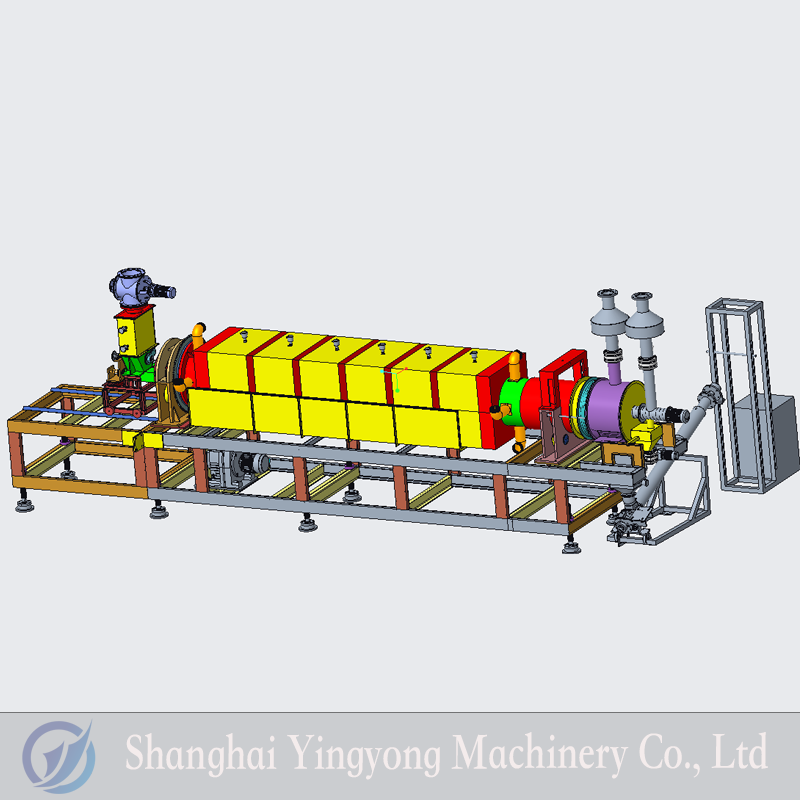

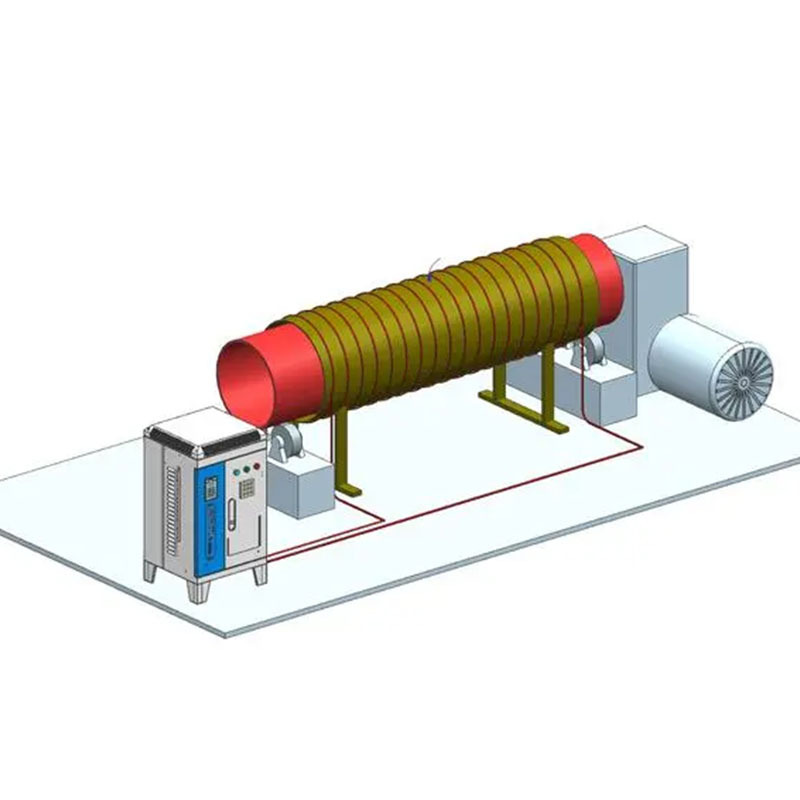

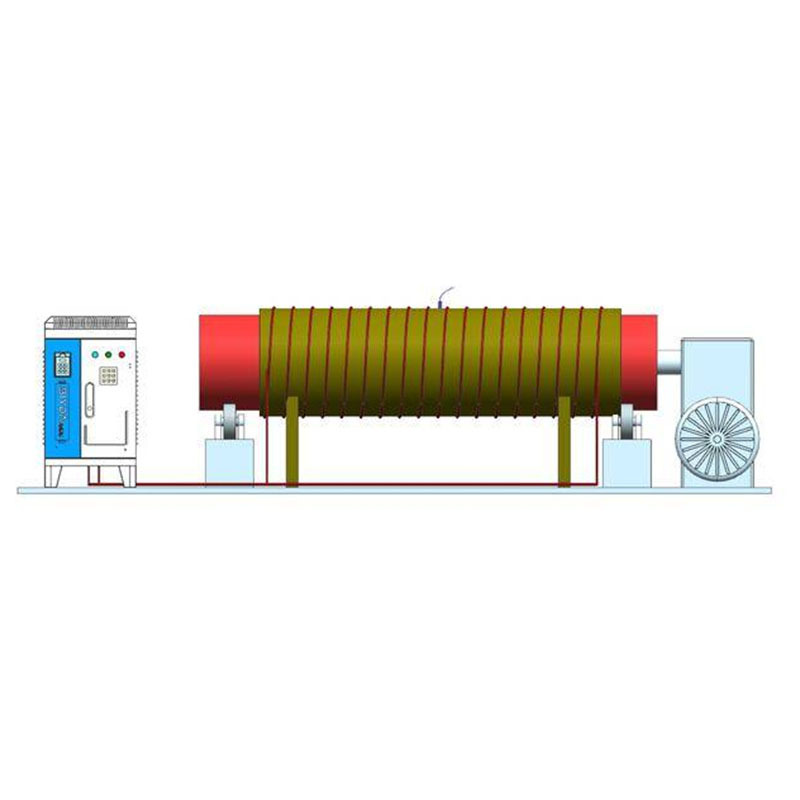

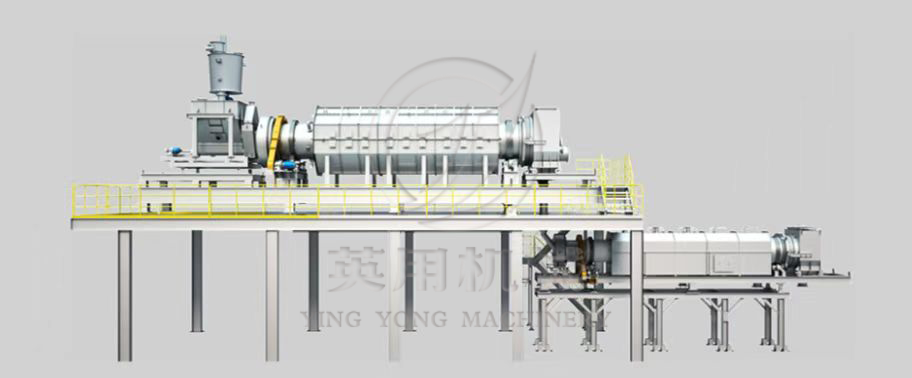

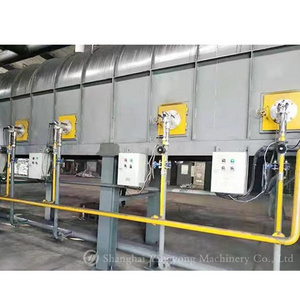

New ore calcination technology

Electromagnetic rotary kiln, successfully put into use. Electromagnetic heating technology, high temperature of 1200, burning ore and producing lime. Our electromagnetic heater, with heating temperature up to 1200 degrees, is perfectly suitable for high temperature heating, high temperature drying, sufficient heat, uniform heating and lower cost in industrial fields such as lime kiln, rotary kiln, reactor, stainless steel pipeline and rotating drum.