- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JS-TTS4

-

Power:

-

15km

-

Material:

-

carbon steel

-

Marketing Type:

-

hot sale 2023

-

Weight (KG):

-

5000 kg

-

Color:

-

Customized Color

Quick Details

-

Production Capacity:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mind

-

Model Number:

-

JS-TTS4

-

Power:

-

15km

-

Material:

-

carbon steel

-

Marketing Type:

-

hot sale 2023

-

Weight (KG):

-

5000 kg

-

Color:

-

Customized Color

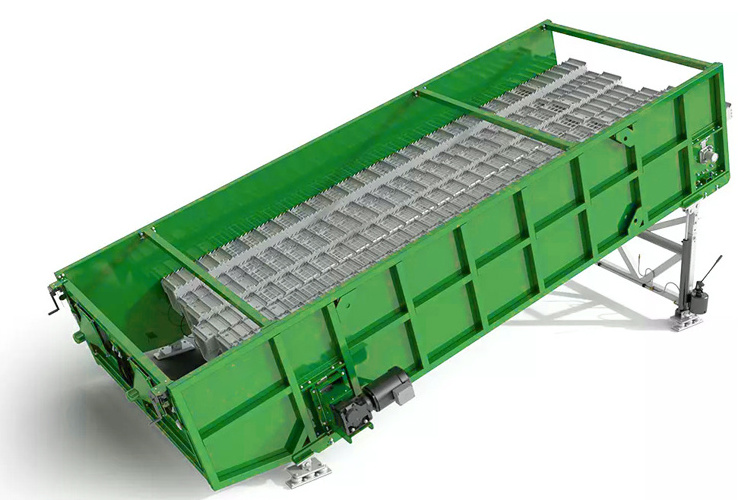

Ballistic Classifier for the Separation of Several Fractions of Packaging Waste, Household Waste, Commercial Waste and Mixed Construction Waste

Ballistic Classifier for the Separation of Several Fractions of Packaging Waste

It separates the material into three fractions. The separation process is done in just one step. The movement of the paddles sets the infeed material into vibration for a vertical as well as a horizontal conveying direction. The vertical acceleration mixes the material thoroughly which leads to excellent separation and yields a high screening quality.

The Ballistic Separator separates the material based on the climbing ability and the irregular ballistic behavior of the components. Rolling and bulky objects, stones, bottles and other hollow bodies submit to the ballistic principle and travel to the lower end of the machine (3D) where they are discharged. Lightweight and flat material, foils, textiles and paper migrate upward, subject to their individual climbing ability, to the overflow at the upper end of the machine (2D). During this process, the lightweight matter is hurled up repeatedly. By the time the matter lands on the screen, most of the fine debris clinging to it (such as moist soil or dust) will have been removed. A third fraction is achieved as a sieve fraction by the perforation of the sieve on the paddles. The size of the sieve grid can be chosen according to the material.

The machine is driven by an electric gear motor. The corresponding frequency converter is also supplied. The transfer of the torque onto the crankshaft at the output side is done by the paddles. The sieve grids are easily exchangeable. Maintenance of the ballistic classifier is made easy by maintenance openings which are secured with safety door switches.

| Model | MS04 | MS06 | MS08 | MS10 | MS12 |

| Paddle quantity | 4 | 6 | 8 | 10 | 12 |

| Paddle length | 5.5 mm | 5.5 mm | 5.5m | 5.5m | 5.5m |

| Angle adjustment | 0-30° | 0-30° | 0-30° | 0-30° | 0-30° |

| Sieve hole size | 10-80 mm | 10-80 mm | 10-80mm | 10-80 mm | 10-80 mm |

| Fan number | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 |

| Power | 5.5kw | 7.5kw | 11kw | 11kw | 22kw |

| Throughput | 0-30 m³/h | 30-50 m³/h | 50-70 m³/h | 70-90 m³/h | 90-120 m³/h |

----------------------------

| This is the advantage of the comprehensive finger screen . 1. The structure is simple and compact, the appearance is beautiful, and the rigidity of the whole machine and the strength of each part are high; 2.Relatively Small size,light weight,large processing capacity per unit of equipment volume and weight, whichis convenientfor system process layout 3.Relatively low energy consumption and high screening efficiency; 4,Easyinstallation and debugging, stable and reliable operation easy operation and maintenance; 5. Modular design of screen surface structure and type, easyto replace, and can meet the needs of different operations | |

| The trommel screen is mainly composed of a motorreducertrommel deviceframe sealing cover and inlet andoutlet.The trommel device is installed obliguely on the frame.The motor is connected with the trommel device through the reducer and the coupling, and the trommel device is driven around it When the material enters the trommel devicethe materials on the screen surface are turned over and rolled due to the inclination and rotation of the drum device so tha the qualified materials(under-screen products) are discharged through the outer screen of the drumand the unqualified materials(over-screen products) are discharged through the end of the drum | |

| The ballistic seperator is a device for sorting according to the shape and specific gravity of the sorted materials,It is an ideal sorting seperator for recycling and sorting domestic waste, pressed kitchen waste, paper recycling and other industries. The ballistic seperator drives the screen plate to move up and down through the eccentric shaft, so that the screened material on the screen plate is shaken and scattered into heav, rolling 3D material parts(such as plastic bottles,wood cans,etc) and light, flat 2D materials Part (flm,paper, cardboard) and part of the material under sieve (sand,food residue), which is convenient for subsequent processing. | |

| Disc screenalso known as disc screen and star screen, is a sorting equipment that separates materials of different sizes and shapes through the rolling of the disc | |

| The air drum separation technology of waste is a traditional sorting method, which has been widely used in various solid waste recycling and resource recovery fields,In the process of solid waste treatment and resource recovery in developed countries such as Europe and the United States, various kinds of air drum separators are one of the necessary equipments. The main principle is separating the light and small substances from the heavy substances in the material and carrying them away upwards or into the setting chamber in the horizontal direction to separate the light substances in the air by the principle of aerodynamics and under the action of the controllable positive pressure air flow, The light material is carried out by the light material conveyor, The heavy materials will be carried out because they can't support their gravity to settle on the heavy material discharge conveyor due to the upward air flow. | |

| The manual sorting platform consists of belt conveyor, platform,silo,safety protection device,light steel workshop (optional) etc, material is along with material to the sorting platform. Such as plastic, paper, fabric, battery, glass etc will be sorted and put to different silos by workers. The left material will go next step. There is a silo for every station at both sides of sorting platform. | |

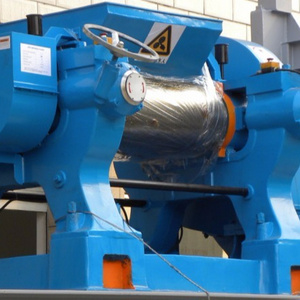

| permanent overhead self-cleaning magnetic separator is suspended over a conveyor or head pulley to remove ferrous metals.Metal is attracted by the self cleaning model and is automatically and continuously removed from the magnet face by a belt that travels around the body of the magnet. No external power source is required for the magnet. Magnetic Separators may also be placed at and incline.Custom Magnetic Separators can be made on request. |

1. In which applications can ballistic separators be used and how do they work?

Ballistic separators are suitable for many types of sorting systems, such as but not limited to single- or dual-stream systems for residential recyclables, commercial recyclables, solid waste, waste to energy (fuel preparation), etc.

2. How are ballistics used in a sorting system?

Ballistic separation is used to do three distinct separations: flexible materials, rigid materials and to screen out a certain

size fraction of material. Similar to a conventional disc screen, the three-dimensional/rigid items, such as containers, will

tumble back, and the flat/flexible items, such as paper and plastic film, will climb to the top front portion of the machine.

Finally, the ballistic separator’s paddles are fitted with replaceable screening plates that are used to screen out material of a certain size as determined by the application.

3. What are the ballistic separator’s advantages compared with a regular star screen?

The ballistic separator has multiple advantages over a conventional rubber star screen. The most appreciated benefit is certainly the lower operational cost of the machine: There are no rubber discs to wear out, and the elliptical movement does not result in the wrapping of long and stringy flexible items, which is what happens on the spinning shaft of a regular screen. Together, these two main aspects translate to more uptime with lower, almost nonexistent, wear parts replacement and much lower labor costs related to cleaning the screen. Also notable, the ballistic separator has a compact footprint that makes it easy to integrate and retrofit within sorting systems, it does a better and more constant job at separation than a regular star screen and also consumes less energy than a comparable capacity star screen.

4. How can this equipment improve quality and recovery in the sorting process?

The ballistic separator has the advantage of not having high wear items like rubber discs, which translates to more constant recovery of material. As rubber discs wear down, the quality of the separation changes, and good commodities are lost to other streams or create unwanted contamination in other places.

5. Can the ballistic separator handle the same throughput as a star screen?

Contrary to what some believe or suggest, the use of ballistic separators does not limit the capacity of a single-stream system. It has been argued that disc screens handle a higher volume of material with better efficiency and purity. The key is properly integrating the ballistics so that they are not installed in a cascade but rather in parallel and in conjunction with other key equipment. Replacing star screens with an equal number of ballistic separators will maintain the same

Packaging and Shipping

| Product Name | Waste Sorting and Recycling Plant |

| Container Size | 20GP, 40GP, 40HQ, etc. |

| Loading Port | Qingdao, Tianjin or Shanghai. |

| Delivery Time |

1.The machines will be packed with bubble wrap or wooden boxes, then fixed tightly.

2.The empty container will be delivered from the port to the factory. 3.The machines and containers will be sent to the port. |