- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RFM drywall metal stud making machine

-

Voltage:

-

380V 50Hz, 3Phases

-

Dimension(L*W*H):

-

7.7*1.65*1.55

-

Weight:

-

6.2 kg

-

Warranty:

-

1year for drywall metal stud making machine

-

name:

-

automatic drywall metal stud making machine

-

Frame:

-

steel

-

roller:

-

Cr12

-

warrantee:

-

1year for drywall metal stud making machine

-

Cutting blade material:

-

Cr12 Quenched

-

advantage:

-

fully automatic drywall metal stud making machine

-

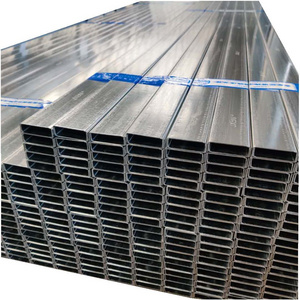

Raw material:

-

Galvanized Sheet

-

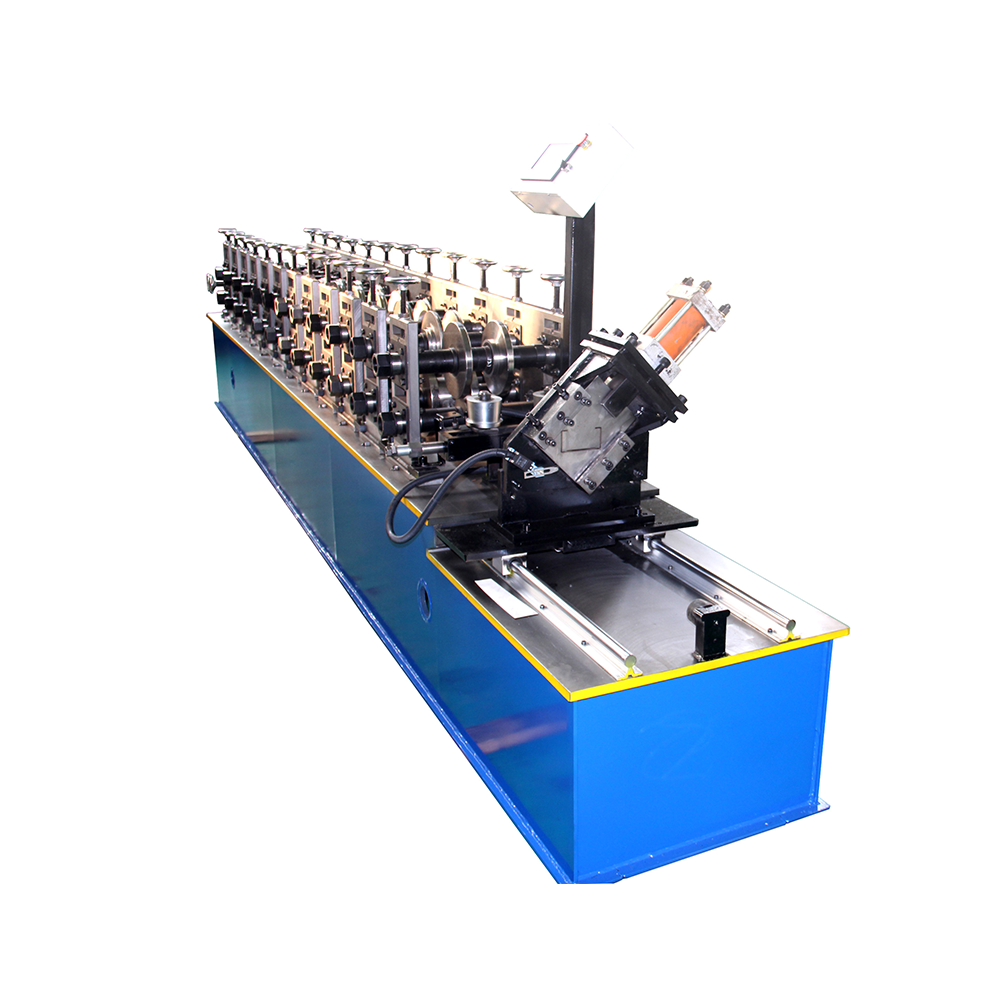

Color:

-

blue

-

Product name:

-

C channel

-

Usage:

-

Building

Quick Details

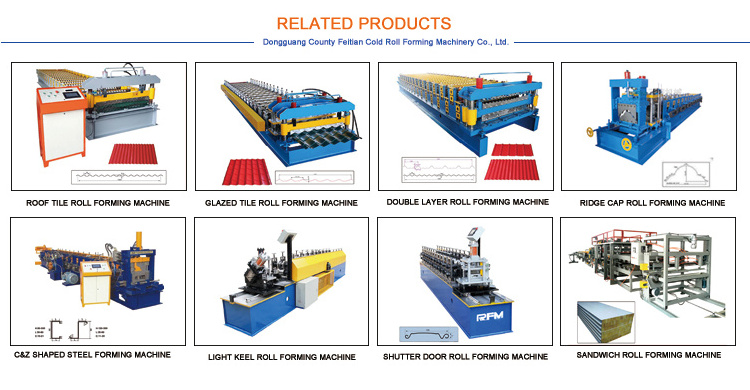

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

3-6m/minute

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RFM drywall metal stud making machine

-

Voltage:

-

380V 50Hz, 3Phases

-

Dimension(L*W*H):

-

7.7*1.65*1.55

-

Weight:

-

6.2 kg

-

Warranty:

-

1year for drywall metal stud making machine

-

name:

-

automatic drywall metal stud making machine

-

Frame:

-

steel

-

roller:

-

Cr12

-

warrantee:

-

1year for drywall metal stud making machine

-

Cutting blade material:

-

Cr12 Quenched

-

advantage:

-

fully automatic drywall metal stud making machine

-

Raw material:

-

Galvanized Sheet

-

Color:

-

blue

-

Product name:

-

C channel

-

Usage:

-

Building

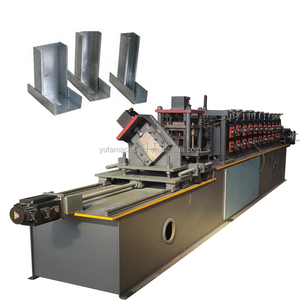

Machine manufacture C profile drywall stud metal making machine drywall profile production line

Summary

1). To design and make the best roll forming machine, we took EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 17+ years experience ;

3). We achieves that the machine capacity is double of the competitors;

4). The machine working speed can be 60m/min ;

5). Very easy to install and operate the roll forming machine.

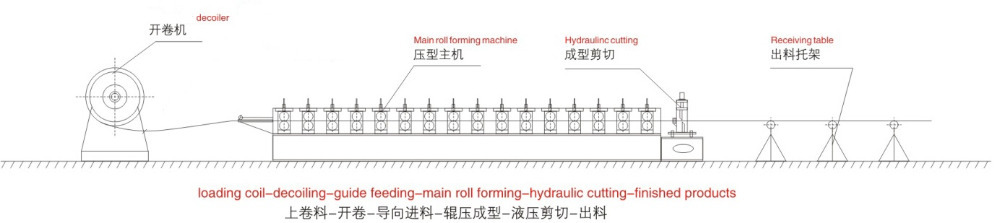

Machine working flow:

Machine Technical Specifications:

About raw material and product for roll forming machine

|

Material&product |

Feeding width |

according to profile |

|

Effective width |

according to profile |

|

|

Raw material |

PPGI |

|

|

Thickness |

0.3-0.7mm |

|

|

Yield strength |

280-350 MPA |

What the main forming machine will be?→as below

|

Main Forming machine |

Forming steps |

12 steps |

|

Shaft diameter |

40mm |

|

|

Machine stand |

Individual Arch Plate |

|

|

Machine frame |

steel plate welded |

|

|

roller material |

Cr12 |

|

|

shaft material |

45# steel with quenching and tempering |

|

|

Work speed |

standard: 20---25m/min; 45---60m/min |

|

|

Transport |

By gear |

|

|

Power of main machine |

4kw |

|

|

Voltage |

380V-50HZ-3P(as required) |

|

|

Machine dimension |

5.5*0.8*1.5m |

|

|

Machine weight |

About 2.5T |

|

|

Machine color |

Yellow and blue(as required) |

|

|

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working Feature : Ensure stability , precision and lifetime. |

||

|

Manual decoiler Inner diameter:450-550mm Outer diameter:1500mm Max Coil width:3 00 mm Capacity: 1. 5 T Decoiler dimension:1.5*1.5*1.5m Decoiler weight:355KGS Quantity: 1set Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system |

|

|

Control System 1. Screen: touch screen 2.PLC: Delta 3.Automatic length measurement 4.Automatic quantity measurement 5.Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved 6.Length inaccuracy can be amended easily |

|

|

Hydraulic c uttin g S ystem 1. Hydraulic Station:1set 2. With hydraulic station, motor 4KW 3. Hydraulic cutting 4. Blade material: Cr12 steel with quenched treated 60-62℃ 5. Cutting system: Advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor. |

|

|

Output fram

|

|

|

|

Forming device

1 .Roller station: 1 3 stations 2 .Shaft material: 45# steel Outer diameter:40 or50 mm Roller material: GCr12 3 .Transport: gear 4 .Forming Speed: 0-25 m/min 5 .Motor:4 kw 6 .Voltage:380v,50Hz,3phase |

Our company is located in Botou City of Hebei Province, next to 104 National Highway. We are specialized in producing different types of automatic cold roll forming machines, such as stone-coated roofing tile line, Light keel roll forming machine, shutter and door frame roll forming machine and automatic partial adjustment C purlin machine.

At present, steel construction is widely used and in great demand. In order to meet the increasing market demand for roll forming machines in different shapes of metal sheets, we have made great investment to improve flawless techniques. Our professional technicians and skilled workers ensure high quality products for our customers with perfect quality management and testing systems.

The success of our company comes from success and development of our customers. We bear this in mind in the whole process from design, product research and development to after sales service. What we value is reputation and service, what we sell is quality and technology.

We warmly welcome old and new clients from all over the world to visit our company and establish business relationships with us. We do believe our mutual cooperation will create a brilliant future.

If you are interested in our products,and want to know more details,

you can click the link below and send us your inquiry.

we will reply immediately.