- Product Details

- {{item.text}}

Quick Details

-

Electrical conductivity:

-

≥100%IACS

-

Side camber:

-

L≤8mm/1000mm

-

Conductor Material:

-

copper

-

Type:

-

bare

-

Copper purity:

-

Cu≥99.97%

-

Tensile strength:

-

≥150MPa

-

Application:

-

Machine Automatic Soldering

-

Approved:

-

CE,RoHS,TUV

-

Base copper trademark:

-

Oxygen-free copper C1022

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

MARS ROCK

-

Model Number:

-

0.2*1.5mm

-

Electrical conductivity:

-

≥100%IACS

-

Side camber:

-

L≤8mm/1000mm

-

Conductor Material:

-

copper

-

Type:

-

bare

-

Copper purity:

-

Cu≥99.97%

-

Tensile strength:

-

≥150MPa

-

Application:

-

Machine Automatic Soldering

-

Approved:

-

CE,RoHS,TUV

-

Base copper trademark:

-

Oxygen-free copper C1022

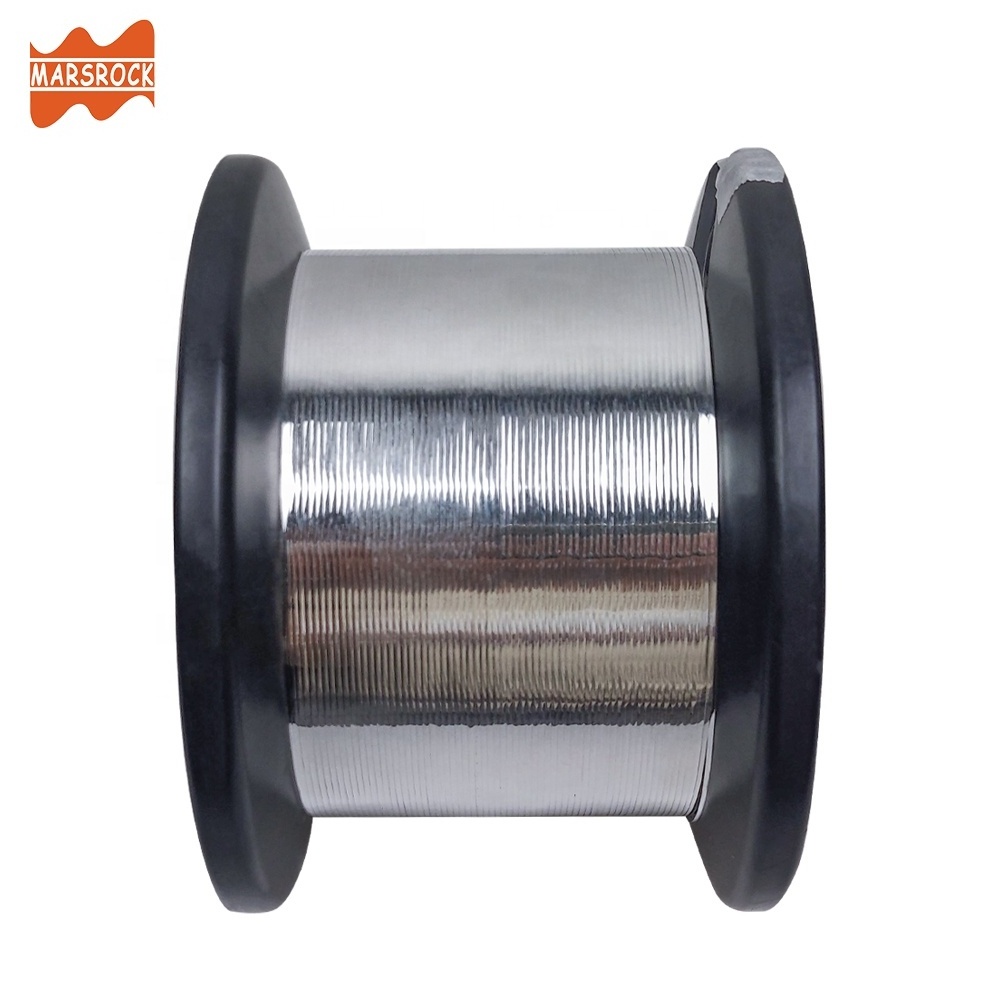

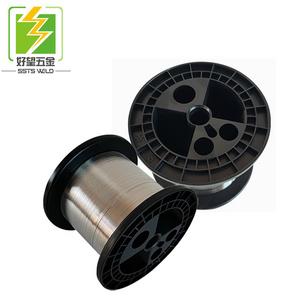

About our PV Ribbon Production

As a professional PV RIBBON supplier, we are specializing in the area of R&D, production and sales of tinned-copper ribbon for solar photovoltaic modules, as well as the area of providing solutions to photovoltaic welding. We will always adhere to the high quality but low cost of development ideas, uphold quality first, credit supreme management idea, can according to the requirements of supers provide all kinds of solar cell module with cooper tape.

We succeeded in developing the super soft tinned-copper ribbon and spool ribbon exclusively for automatic stringer independently which has effectively reduced cell crack and breakage ratio during customer working process, which has cut the cost as well as strengthened the power, quality and performance of products.

We succeeded in developing the super soft tinned-copper ribbon and spool ribbon exclusively for automatic stringer independently which has effectively reduced cell crack and breakage ratio during customer working process, which has cut the cost as well as strengthened the power, quality and performance of products.

Product Description

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Fujian

|

|

Brand Name

|

MARS ROCK

|

|

Model Number

|

0.2*1.5mm

|

|

Electrical conductivity

|

≥100%IACS

|

|

Side camber

|

L≤8mm/1000mm

|

|

Conductor Material

|

copper

|

|

Type

|

bare

|

|

Copper purity

|

Cu≥99.97%

|

|

Tensile strength

|

≥150MPa

|

|

Application

|

Machine Automatic Soldering

|

|

Approved

|

CE,RoHS,TUV

|

|

Base copper trademark

|

Oxygen-free copper C1022

|

|

Width

|

Thick*Width

|

Thickness(mm)

|

|

Reference Length(2KGS/4.4Lb)

|

|

|

||||||

|

|

|

Base Copper

|

Side Coat

|

Meters

|

Inch

|

Feet

|

||||||

|

0.6mm

|

0.12*0.6mm

|

0.05

|

0.015

|

3,121

|

122,878

|

10,240

|

||||||

|

0.8mm

|

0.08*0.8mm

|

0.05

|

0.015

|

3,511

|

138,238

|

11,520

|

||||||

|

|

0.10*0.8mm

|

0.05

|

0.025

|

2,809

|

110,591

|

9,216

|

||||||

|

1mm

|

0.08*1.0mm

|

0.05

|

0.015

|

2,809

|

110,591

|

9,216

|

||||||

|

|

0.1*1.0mm

|

0.05

|

0.025

|

2,247

|

88,465

|

7,372

|

||||||

|

1.5mm

|

0.08*1.5mm

|

0.05

|

0.025

|

1,873

|

73,740

|

6,145

|

||||||

|

|

0.10*1.5mm

|

0.05

|

0.025

|

1,498

|

58,976

|

4,915

|

||||||

|

|

0.12*1.5mm

|

0.15

|

0.025

|

1,248

|

49,134

|

4,094

|

||||||

|

|

0.15*1.5mm

|

0.1

|

0.025

|

999

|

39,331

|

3,278

|

||||||

|

|

0.2*1.5mm

|

0.15

|

0.025

|

749

|

29,488

|

2,457

|

||||||

|

1.6mm

|

0.15*1.6mm

|

0.1

|

0.025

|

936

|

36,850

|

3,071

|

||||||

|

|

0.18*1.6mm

|

0.125

|

0.0275

|

780

|

30,709

|

2,559

|

||||||

|

|

0.20*1.6mm

|

0.15

|

0.025

|

702

|

27,638

|

2,303

|

||||||

|

1.8mm

|

0.12*1.8mm

|

0.15

|

0.025

|

1,040

|

40,945

|

3,412

|

||||||

|

|

0.15*1.8mm

|

0.1

|

0.025

|

832

|

32,756

|

2,730

|

||||||

|

|

0.16*1.8mm

|

0.11

|

0.025

|

780

|

30,709

|

2,559

|

||||||

|

|

0.18*1.8mm

|

0.125

|

0.0275

|

694

|

27,323

|

2,277

|

||||||

|

|

0.20*1.8mm

|

0.15

|

0.025

|

624

|

24,567

|

2,047

|

||||||

|

2mm

|

0.10*2.0mm

|

0.05

|

0.025

|

1,124

|

44,252

|

3,688

|

||||||

|

|

0.12*2.0mm

|

0.15

|

0.025

|

936

|

36,850

|

3,071

|

||||||

|

|

0.13*2.0mm

|

0.08

|

0.025

|

864

|

34,016

|

2,835

|

||||||

|

|

0.15*2.0mm

|

0.1

|

0.025

|

749

|

29,488

|

2,457

|

||||||

|

|

0.16*2.0mm

|

0.11

|

0.025

|

702

|

27,638

|

2,303

|

||||||

|

|

0.18*2.0mm

|

0.125

|

0.0275

|

624

|

24,567

|

2,047

|

||||||

|

|

0.20*2.0mm

|

0.15

|

0.025

|

562

|

22,126

|

1,844

|

||||||

|

Remark:

|

|

|

|

|

|

|

||||||

|

1.

|

Above data only for reference,

|

|

|

|

|

|

||||||

|

2.

|

Tolearance: +/-0.05mm

|

|

|

|

|

|

||||||

|

3.

|

Coating Component

|

|

|

|

|

|

||||||

|

|

1)Lead-Free:Sn 98%, Ag 2%(Optional)

|

|

|

|

|

|

||||||

|

|

2)Leady A.Sn 60% Pb 40% B.Sn 63% Pb 37% C.Sn 62% Pb 36% Ag 2% D.Sn 60% Pb 39.5% Ag 0.5%

|

|

|

|

|

|

||||||

Product Application

Product Making Crafts Process

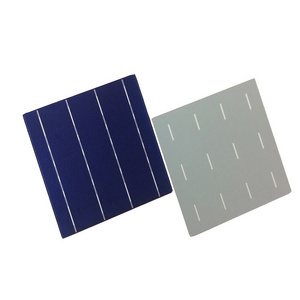

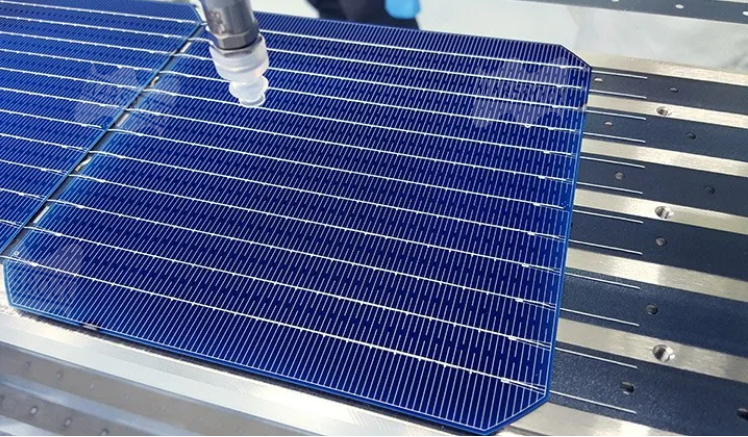

PV ribbon is composed of Copper and coating alloys, and divided into Tabbing Ribbon and Bus bar ribbon.

1. Tabbing Ribbon

Tabbing Ribbon commonly connects the positive and negative sides of the cells in series.

2. Bus bar Ribbon

Bus bar Ribbon concentrates the cell stringing into junction box and channels electrical current.

1. Tabbing Ribbon

Tabbing Ribbon commonly connects the positive and negative sides of the cells in series.

2. Bus bar Ribbon

Bus bar Ribbon concentrates the cell stringing into junction box and channels electrical current.

The coating type is determined by the customer’s design and demand. It is divided into leaded and dead-free coating. At moment the leaded coating type is widely used, but in the future it will be developed to lead-free coating type.

Main coating alloy types and melting temperatures as follows:

Main coating alloy types and melting temperatures as follows:

Packing & Delivery

Hot Searches