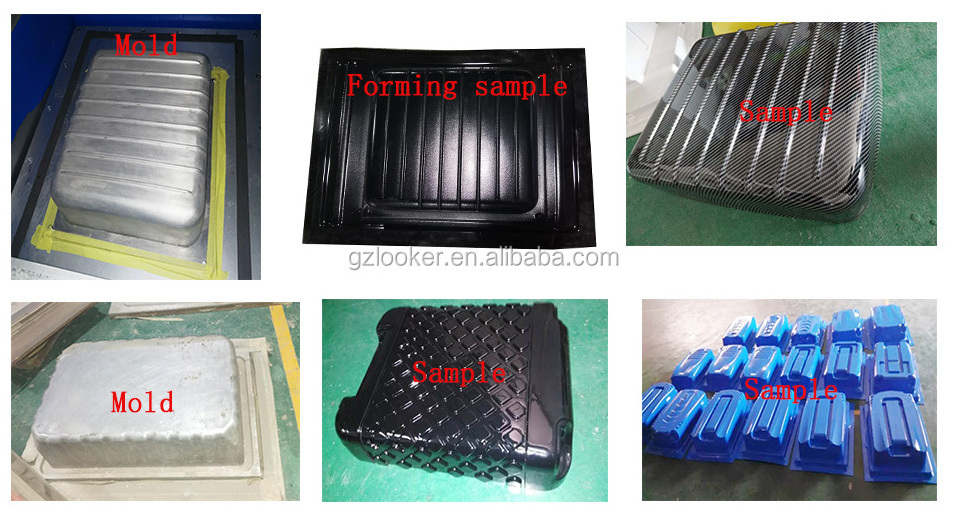

Name: Bottom mould & forming area

Closed region, specially suitable for thick material.

T his machine can heat the thick material (PVC, PP, PS, PE, PET, PETG, POF, APET, ABS, OPP, Acrylic, etc) and make them soft then vacuum suction, then can transform sheet material into various plastic blister.Also,it is widely use in luggage, automobile, medical equipments, refrigerator, bathtub,lamps etc.It can replace injection molding and fiberglass products,highly save energy and mold costs.

1. High performance small motor drives heat furnace, fast and smooth.

2. Ceramic heating elements, control the temperature of each heating element separately, suitable for the product of complex structure.

3. The area of bottom mould is closed, air blows up after the material being heated and soft which can avoid material sinking, ensure the uniform thickness of finished product.

4. Bottom mould is driven by big cylinder, rack positioning can ensure running smoothly.

5. Large air cooling motor which can insure finished good rapid cooling.

6. Equipped with water cooling system, can further rapid cooling.

7. Double-furnace can heat the material on two surfaces, highly increase working speed,especially suitable for thick material(5-10mm).

|

Parameters

|

|

|

|

Model

|

LK-90B

|

|

|

Power supply

|

AC380 50/60HZ

|

|

|

Power

|

35KW

|

|

|

Max. forming length

|

900mm(customizable)

|

|

|

Max. forming width

|

750mm(customizable)

|

|

|

Max. forming height

|

180mm(customizable)

|

|

|

Material thickness

|

1.0~5.0mm

|

|

|

Output

|

100-200moulds/H

|

|

|

Net weight

|

3000KG

|

|

Name: Bottom mould & forming area

Closed region, specially suitable for thick material.

Name:

Control panel

Individual control PLC for each working station,Digital temperature controller on the PLC ,visual and easy setting.

Solid state voltage regulators can control each heating boards individuallly.

Name:

PLC

Brand: Delta

Famous PLC brand,let the whole machine control system more stable and durable.

* Operation manual.

* Assemble video, Working video, Setting video.

Normally, customer can assemble and operate the machine correctly with these manuals and videos.

* Engineers available to service machinery overseas.

* Our engineers are skillful and fluent in English.

* Went to Philippines to train how to instal the machine and how to use the machine.

* Engineers available to service machinery overseas.

* Our engineers are skillful and fluent in English.

* Went to Sri Lanka to train how to instal the machine and how to use the machine.

* Engineers available to service machinery overseas.

* Our engineers are skillful and fluent in English.

* Went to Tunisia to train how to instal the machine and how to use the machine.