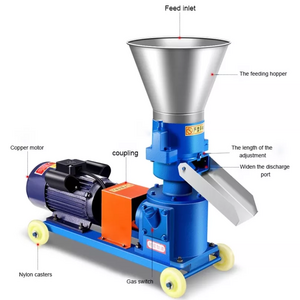

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

850*350*750mm, 800*280*720mm

-

Weight:

-

95 kg, 100kg

-

Marketing Type:

-

Other

-

Name:

-

feed pellet machine

-

Model:

-

KPM-125

-

Power:

-

4000w

-

Raw material:

-

Grain, grass,etc

-

Pellet size:

-

customized

-

Machine Material:

-

Alloy Steel

-

Function:

-

Making feed for animal

Quick Details

-

Max. Capacity:

-

80-100kg/h

-

Place of Origin:

-

China

-

Voltage:

-

110V/220V/380V, 220v/380v

-

Dimension(L*W*H):

-

850*350*750mm, 800*280*720mm

-

Weight:

-

95 kg, 100kg

-

Marketing Type:

-

Other

-

Name:

-

feed pellet machine

-

Model:

-

KPM-125

-

Power:

-

4000w

-

Raw material:

-

Grain, grass,etc

-

Pellet size:

-

customized

-

Machine Material:

-

Alloy Steel

-

Function:

-

Making feed for animal

Feed processing machines /Feed pellet machine

|

WhatsApp: +86 137 0393 7124

Email: nancy@chkellenmachine.com

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Feed pellet machine (also known as: feed granulator, pellet feed forming machine) belongs to feed granulation equipment. It is a feed processing machine that uses corn, soybean meal, straw, grass, rice husk and so on as raw materials and directly presses them into particles after crushing the raw materials.

Products Description

Feed granulator is divided into circular model feed granulator, flat model feed granulator and double roller feed granulator; According to the application, it can be divided into: small household particle feed machine, poultry feed granulator, small poultry particle feed machine, fish feed granulator, rabbit feed granulator, pig feed granulator and straw feed granulator; According to the production, it can be divided into straw feed granulator, wheat bran feed granulator, soybean meal feed granulator, corn. Different kinds of feed granulators are classified according to different appearance and production methods.

Product molds

Different pellet die diameters ,suit different animals:

a.

2mm is suitable for aquaculture animals, such as shrimp, small fish, crabs, young birds

b.

3MM is suitable for aquaculture, young chickens, young ducks, young rabbits, young peacocks, aquatic products,

c.

4MMis suitable for breeding, chickens, ducks, fish, rabbits, pigeons, peacock birds, etc.

d.

6MMmillstone is suitable for breeding pigs, horses, cattle, sheep, dogs and other domestic animals

(2mm,2.5mm,3mm,4mm,6mm,8mm,10mm)pellet size for your choose.

Size Information

Scope:

Feed granulator is widely used in large, medium and small aquaculture, grain feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing plants.

Product Details

Pictures display

Definition

How to reduce the cost of feed while meeting the nutritional needs of various livestock and poultry has become the primary problem that the vast number of farmers and feed industry urgently need to solve. Straw biochemical protein feed technology is to soften the lignin of crop straw through technical measures such as crushing, fermentation and granulation. Crude protein, crude fiber, crude fat and so on are degraded into substances that are easy to digest and absorb for livestock. At the same time, a large amount of thallus protein is produced during fermentation. After fermentation, it becomes soft and sweet. Granulation increases the palatability of livestock and poultry. The average level of crude protein and amino acid will increase, the levels of cystine and histidine have also been greatly improved, the contents of sugar and fat have increased, and vitamins and growth factors such as B, D and E are produced. Then, they are mixed with other raw materials to prepare full-price feed, which is made into nutrient-rich feed particles by machine pressing the pellet feed, thus greatly increasing the feed intake of livestock and accelerating the growth. It not only reduces the grain input (per ton of straw feed is equivalent to the nutritional value of 270kg of grain feed), saves the feed cost, but also increases the income of the breeders.

Main features

1. Simple structure, wide adaptability, small floor area and low noise.

2. Powdered feed and grass powder can be granulated without adding a little liquid, so the moisture content of granulated feed is basically the moisture content of materials before granulation, which is more conducive to storage.

3. Chicken, duck, fish, etc. can obtain higher economic benefits than mixed powdered feed. 4. Dry material processing, the produced feed particles have high hardness, smooth surface and internal curing, which can improve the digestion and absorption of nutrition.

4. The process of particle formation can denatate the trypsin resistance factors in grains and beans, reduce the adverse effects on digestion, kill various parasite eggs and other pathogenic microorganisms, and reduce various parasites and digestive system diseases.

Package and Delivery

Our company

Why choose us?

Hot Searches