- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

none

-

Standard or Nonstandard:

-

Nonstandard

-

Color:

-

black

-

Product name:

-

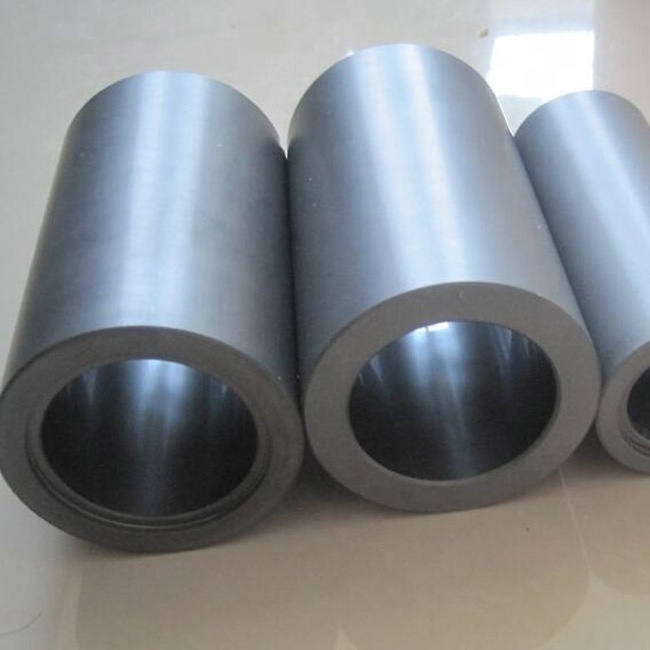

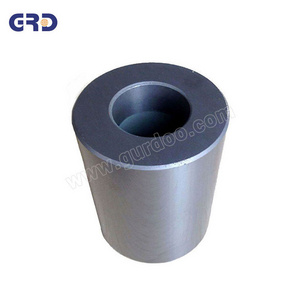

Silicon Carbide SiC Bushing with lower price

-

Size:

-

Customer Demand

-

sample:

-

available

-

package:

-

carton or wooden box

Quick Details

-

Material:

-

Silicon Carbide

-

Place of Origin:

-

Henan, China

-

Model Number:

-

STA-SC002

-

Brand Name:

-

none

-

Standard or Nonstandard:

-

Nonstandard

-

Color:

-

black

-

Product name:

-

Silicon Carbide SiC Bushing with lower price

-

Size:

-

Customer Demand

-

sample:

-

available

-

package:

-

carton or wooden box

STA High quality various silicon carbide SiC bushing parts is for water pump mechanical seal.

Introduction of Silicon Carbide:

Silicon carbide (SiC), also known as carborundum, is a compound of silicon and carbon with a chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Silicon carbide powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics which are widely used in applications requiring high endurance, such as car brakes and ceramic plates in bulletproof vests. Electronic applications of silicon carbide as light emitting diode and detector in early radios have been demonstrated around 1907, and nowadays SiC is widely used in high-temperature semiconductor electronics. Large single crystals of silicon carbide can be grown by the Lely method; they can be cut into gems known as "synthetic moissanite". Silicon carbide with high surface area can be produced from SiO2 contained in plant material.

Feature of silicon carbide sic bushing / sleeve:

1) Heat shock stability

2) chemical corrosion-resistant

3) High temper-endure (up to 1600°

4) Wearing/corrosion/oxidation resistant

5) Highly performance of mechanical strength

6) Cleaning or etching the hardest sub-surfaces

7) Used for grinding, lapping, and wire saw cutting as well as abrasive blasting.

STA Silicon Carbide Fine Ceramics/Precision silicon carbide (SIC) ceramic rings.

The Ceramic Material for Extreme Applications

Silicon carbide behaves almost like a diamond. It is not only the lightest, but also the hardest ceramic material and has excellent thermal conductivity, low thermal expansion and is very resistant to acids and live.

Properties of Silicon Carbide, SSiC / SiSiC / RiC

|

Properties |

Units |

Silicon Carbide(SiC) |

|||

|

SSiC |

SiSiC |

RSiC |

|||

|

Mechanical |

Density |

g/cm3 |

>3.1 |

>3.02 |

2.6-2.7 |

|

Color |

------- |

Black |

Black |

Gray |

|

|

Water Absorption |

% |

0 |

0 |

16% |

|

|

Vickers Hardness |

Gpa |

24 |

23.5 |

------- |

|

|

Flexural Strength(20°C) |

Mpa |

480 |

460 |

>100 |

|

|

Compressive Strength(20°C) |

Mpa |

3200 |

2500 |

------- |

|

|

Thermal |

Thermal Conductivity (20°C) |

W/m.k |

150 |

125 |

24 |

|

Thermal Shock Resistance (20°C) |

T(C) |

300 |

400 |

------- |

|

|

Maximum Use |

°C |

1600 |

1380 |

1650 |

|

|

Electrical |

Volume Resistivity (25°C) |

Ω.cm |

5x107 |

1 |

------- |

STA is one of the leading manufacturers of advanced ceramic products from China. We supply quality technical ceramic materials and components with competitive price. Our fine ceramics were exported to Europe, North America, Japan, South Korea, Australia, the quality is creditable.

Our available materials for sale are:

alumina(Al2O3), zirconia (ZrO2), Silicon Carbide, Silicon Nitride, Boron Nitride, steatite, metalized ceramics etc.

Our general ceramic parts include:

ceramic tube, ceramic rod, ceramic plate, ceramic disc valve, ceramic wafer, ceramic seal, ceramic valves, ceramic pump plunger, ceramic beam, ceramic roller, ceramic shaft, ceramic screw, ceramic sleeve, ceramic washer, ceramic lamp holder, ceramic insulator, ceramic nozzle, ceramic lining, ceramic guide, ceramic grinding media, ceramic bushing, ceramic substrates, ceramic piston, ceramic ferrule, ceramic ignitor, ceramic bolt and nut, ceramic crucibles etc.

These precision tolerance ceramic components or assemblies are used in a wide range of semiconductor, electronic, electrical, mechanical, chemical, automotive, textile and the other industrial engineering applications, due to their extreme hardness, more resistances to wear, heat, corrosion, high electric insulation and low thermal expansion.

High puriy material make sure high max working temperature,

Tight tolerance make sure the right installation.

Large quantity Crucibles in stock ensured fast delivery

Large capacity reduce crucible prices