- Product Details

- {{item.text}}

Quick Details

-

Area:

-

7.5-14 m2

-

Mesh size:

-

6-50/30-150

-

Feed size:

-

400 mm below

-

Capacity:

-

1700t/h max

-

Vibration frenquency:

-

708/748/755/845 v.p.m

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Layer:

-

1-2

-

Area:

-

7.5-14 m2

-

Mesh size:

-

6-50/30-150

-

Feed size:

-

400 mm below

-

Capacity:

-

1700t/h max

-

Vibration frenquency:

-

708/748/755/845 v.p.m

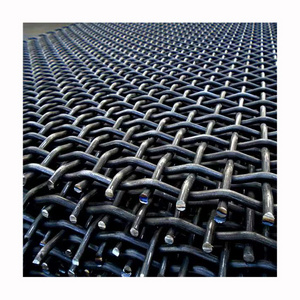

Description of vibrating screen:

Vibrating Screen is widely applied in coal dressing, ore dressing, building material, electricity and chemical industries. It is doing circular movement while at work, and it is of a highly-effective, newly-developed and multilayer machine. With the introduction of eccentric shaft vibration exciter and particular block, the amplitude can be adjustable.

Application of vibrating screen:

The application range of Vibrating Screen: mines, coal, metallurgy, construction materials, chemistry industry.

Working principle of vibrating screen:

When operating, the vibration generator and eccentric shaft is driven by the motor through the spindle coupling to rotate at a high speed. And the strong centrifugal force generated by this rotation impels the screen box to do continuos circular movement compulsorily. The materials on the inclined screen surface keep turn over along with the screen box. The small granularity will move downward the materials and be discharged from the outlet, while the particles stuck in the screen hole can leap out to avoid the blocking of the sieve pit. Thus, again and again the classification and screening is achieved.

Features of vibrating screen:

- Adopt tire coupling and soft connection makes operation smooth.

- Simple structure, easy to repair.

- High capacity and reliability

- Easy maintenance