- Product Details

- {{item.text}}

Quick Details

-

Mould shipping::

-

by sea or by air, according to customers requirement.

-

Surface Finish:

-

Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy

-

Cavity material::

-

P20,718,H13, 2316,2738,S136, and so on

-

Drawing Format:

-

STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other

-

Product Material::

-

Steel, Plastic, plastic:ABS,PP,PC,PS,PA66,PVC, and so on

-

Cavity suirface treatment::

-

polished,electroplating, nitriding and so on

-

Mold Life:

-

300000 shots to 1 million depend on the material of the mold

-

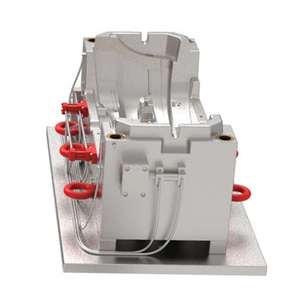

Gate type::

-

Cold runner or hot runner as you require

-

Injection Machines:

-

26

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Shanghai, China

-

Colors Available:

-

Pantone/RAL and other custom colors

-

Mould shipping::

-

by sea or by air, according to customers requirement.

-

Surface Finish:

-

Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy

-

Cavity material::

-

P20,718,H13, 2316,2738,S136, and so on

-

Drawing Format:

-

STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other

-

Product Material::

-

Steel, Plastic, plastic:ABS,PP,PC,PS,PA66,PVC, and so on

-

Cavity suirface treatment::

-

polished,electroplating, nitriding and so on

-

Mold Life:

-

300000 shots to 1 million depend on the material of the mold

-

Gate type::

-

Cold runner or hot runner as you require

-

Injection Machines:

-

26

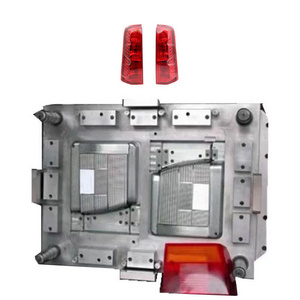

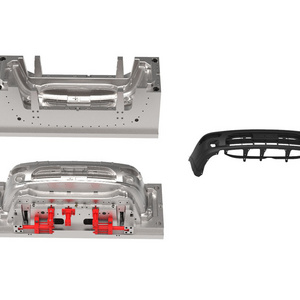

custom creating plastic injection molds with good quality

1-Zetar provide high quality custom plastic injection molded parts

2-Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect

3-Different injection molded parts can pass different certififcation such as UL test, V0 fire resistant test,FDA test,REACH test,SGS test and IP65

4-Zetar can also provide different surface treatment for injection molded parts

5-Commonly use surface treatment for injection molded parts as:Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI

6-Beside making injection molded parts,we also provide printing,welding,assembly and packing service

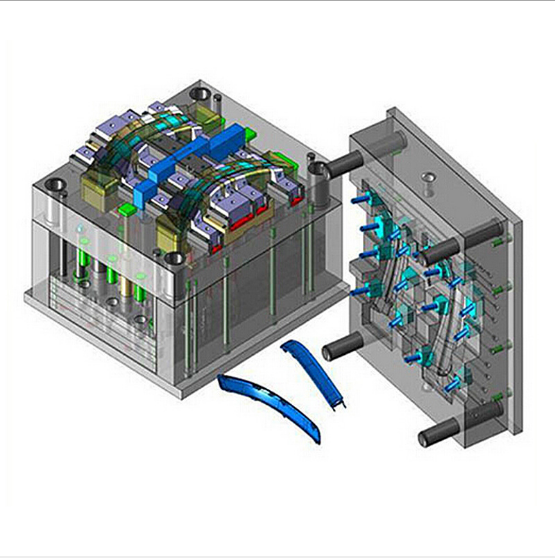

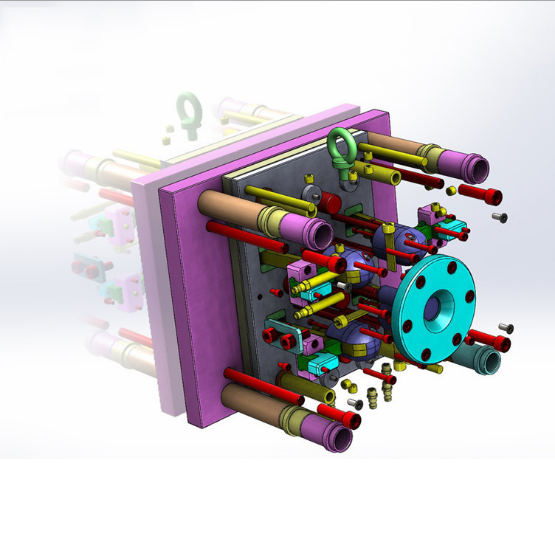

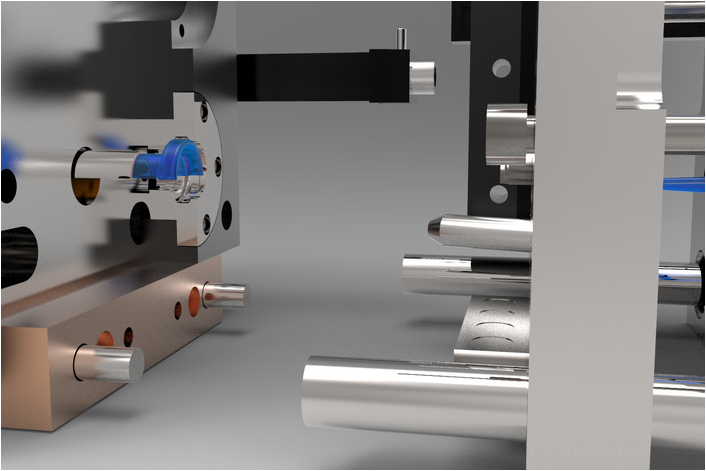

Mold Design

We will communicate&exchange the opinion with customers during Mold Deisgn

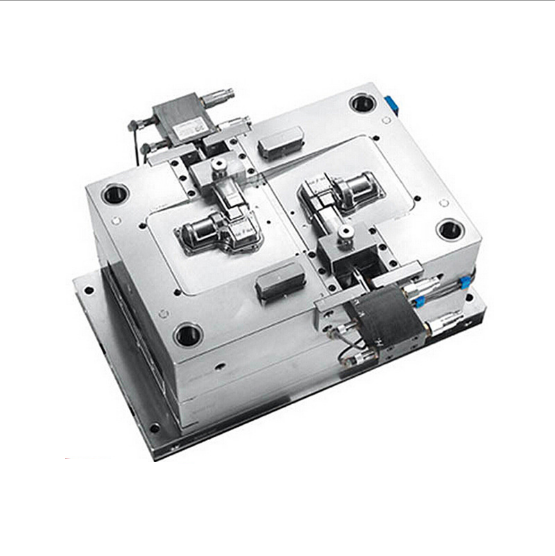

Mold Making

Start to manufacture, we will sent photos to show tooling process.

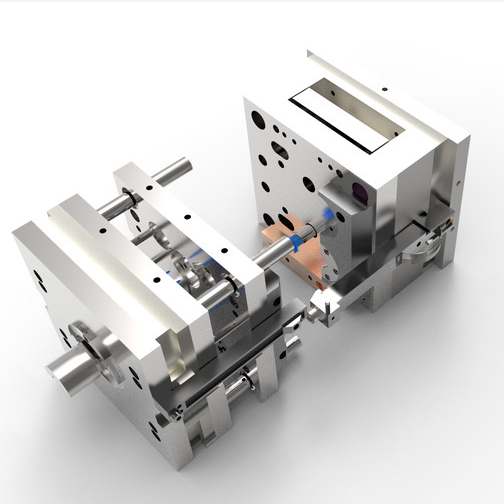

Provide the sample

Once the sample finish,we will send the sample to customer confirm

Mass Production

After customer confirmed the sample, we will start mass production plastic products.

Assembly

We Also Provide Assembly Service For Our Custome r.

Painting&Coating

We can provide coating and rubber coating service for your customers.

Printing

We Also Provide Silk Screen Printing, Pad Printing, Heat Transfer Print Service.

Packaging Box

We also make the packaging box as customer request.

Top Quality Plastic Injection Molding Manufacturer

49% buyers found Plastic Products also liked Top Quality Plastic Injection Molding Manufacturer

China OEM low price custom plastic parts injection molding manufacturer

30% Buyers who searched injection molding bought China OEM low price custom plastic parts injection molding manufacturer

China High Precision Plastic Injection Molding Factory

20% Buyers who searched Plastic injection molding bought China High Precision Plastic Injection Molding Factory

Tom from US like Zetar

This US customer Tom Smith,their company is our first US customer who making tripod products.

We made a set of tripod for them and here is there comments:

Hello Ella,

I got the cases and I am very proud. I wouldn't change a thing! You guys did a wonderful job and please relay that to Zetar team. I will be letting you know here shortly the dimensions of the next case. It is great having a business relationship with you guys. I hope you and your family are doing well and that the weather is beautiful.

Tom

Thomas from NL speak highly of Zetar

Thomas Kuijper from Netherland working in battery industry,we have working with them since 2013 for their battery housings.

Hello Tina,

Cargo arrived.I am happy for all these smooth work.Your team is growing so fast and i like their communication.I believe we soon will have more works for Zetar. I hope you and your family are doing well

Thomas

Chirs from Canada prefer to work with Zetar

Chris from Canada come to visit us in 2017,bring his two molds made in Shenzhen to us for mass production.They under big pressure from kickstater backers,while the factory made molds for them can't do production and molds molding delayed a lot already.

Working with us,Chirs get big success with his kickstarter campaign,and now they are making new version and we already involved in new product design.

1. Are you a trading company or a manufacturer?