Shafts are an important part of many mechanical systems, including pumps, engines and machinery. They act as a medium for power transmission between various components such as gears, pulleys and wheels. Shafts are available in a variety of shapes, sizes and materials, and their selection is determined by the specific needs of an application.

- Product Details

- {{item.text}}

Quick Details

-

Torque Capacity:

-

Customer-Making

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

YR

-

Size:

-

Customer's Drawing Required

-

Certificate:

-

ISO9001

-

Process:

-

Lathing, milling,grinding,drilling

Quick Details

-

Weight (KG):

-

500

-

Core Components:

-

gear shaft

-

Material:

-

42CrMo, 40Cr, C45, Alloy steel, 42CrMo, 40Cr , C45, Alloy steel

-

Torque Capacity:

-

Customer-Making

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

YR

-

Size:

-

Customer's Drawing Required

-

Certificate:

-

ISO9001

-

Process:

-

Lathing, milling,grinding,drilling

Bearing shaft

A bearing shaft is a sort of shaft that helps to sustain rotating machinery components, including gears, pulleys and wheels. It is intended to transfer torque and radial stresses from the component to the bearings, reducing friction and wear.

Bearing shafts can be made of a variety of materials such as stainless steel, carbon steel and alloys. The material chosen is determined by the individual application requirements such as speed, temperature and corrosiveness of the environment.

Pump shafting

Pump shafting is a form of shaft that is used in pumps–machines that transport fluids by mechanical action. Pump shafting experiences significant torque and axial loads, which can result in bending, fatigue and wear.

As such, pump shafting must be constructed with high strength and stiffness as well as exceptional resistance to corrosion and wear.Pump shafting is commonly made of stainless steel, duplex stainless steel and high-strength alloys.

Ground shaft

A ground shaft is a shaft that has been machined to exact tolerances for great accuracy and surface polish. Ground shafts are used in applications that demand exactness, in products such as precision instruments, machine tools and aircraft components.

Grinding the surface of ground shafts removes any flaws, such as scratches, nicks or burrs, all of which can influence the accuracy and effectiveness of the system. Ground shafts can be made of many different materials, such as aluminum, stainless

steel, titanium and tungsten.

Forged Shaft ------Raw Material:

Carbon steel, C-Mn steel, alloy structure steel, alloyed tool steel, cold roll steel, steel for pressure vessel, carburizing

steel, die steel, stainless steel and so on.

Carbon steel, C-Mn steel, alloy structure steel, alloyed tool steel, cold roll steel, steel for pressure vessel, carburizing

steel, die steel, stainless steel and so on.

|

Wind Turbine Shaft

|

42CrMo4, 34CrNiMo6

|

|

Marine Shaft

|

C-Mn steel

|

|

Hydro Turbine Shaft

|

20SiMn

|

|

Roller Shaft

|

70Cr3Mo; 9Cr2Mo; MC1; MC2; MC3

|

|

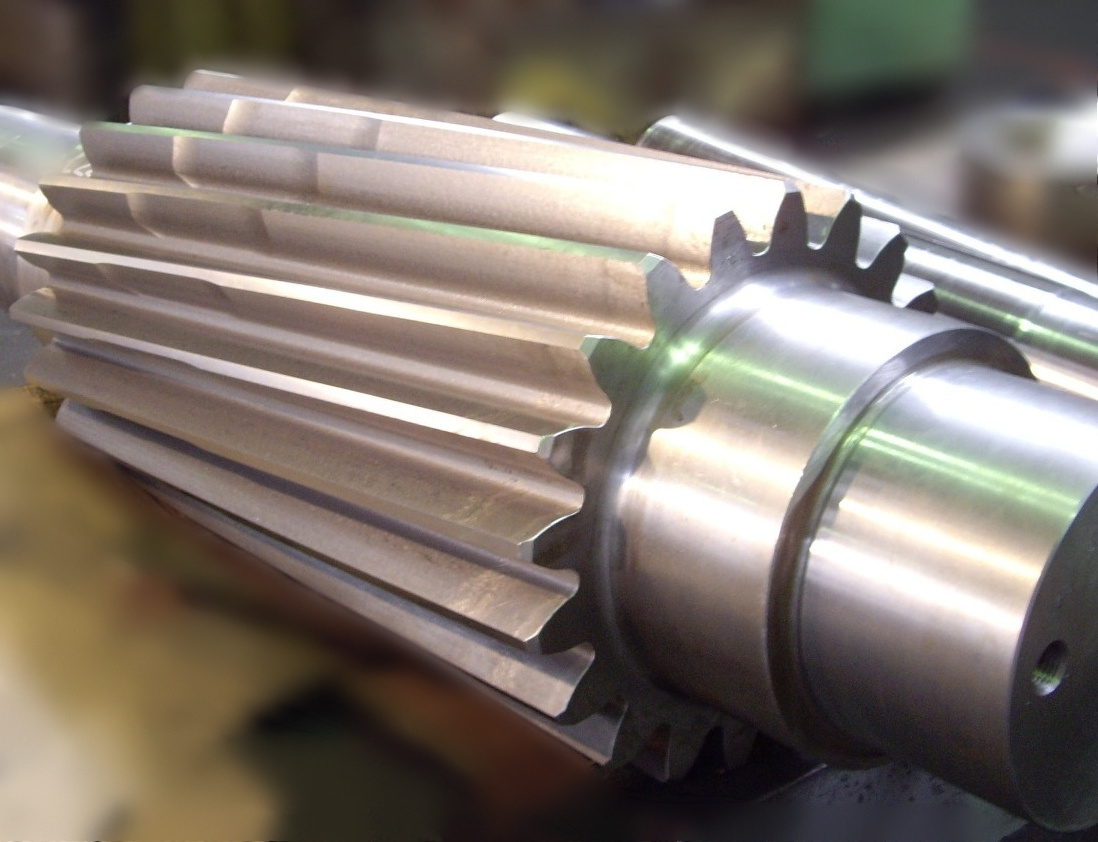

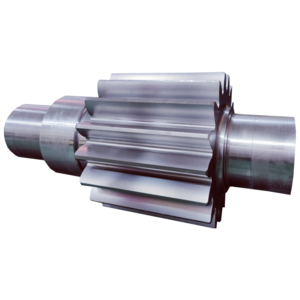

Gear Shaft

|

17CrNiMo6; 18CrNiMo7-6; 20CrNi2Mo; 42CrMo; 47CrNiMo6, 20CrMnMo

|

|

Gear

|

17CrNiMo6; 18CrNiMo7-6; 20CrNi2Mo; 42CrMo; 47CrNiMo6, 20CrMnMo, 30 CrNiMo6

|

|

Pressure Vessel Forgings

|

SA105, SA350 LF2, 16Mn, 20MnMo, 15MnMo, 12Cr2Mo1, 14Cr1Mo, 42CrMo, F304, F316, 17-4PH, 4330, 4336, 4340

|

|

Ring Rolling

|

16Mn, 50Mn, 42CrMo, 15MnV, 35CrMo, A105, 20#, 304, 304L, 316, 316L

|

Please let me know your drawing requirements, and we will do our best to meet your requirements.

You put forward material requirement, mechanical properties and tolerance, maybe full set of engineering Drawing, designing requirement, then our manufacturer will termwise check drawings scrupulously and completely understand technical parameter.There’ll be once or twice technical exchange between both parties, or any ameliorating. Everything is ready, next to manufacturing, acceptance and delivery.

Hot Searches