- Product Details

- {{item.text}}

Quick Details

-

Printing:

-

Silk screen printing

-

Monofilament Style:

-

Yes

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DY screen printing mesh

-

Model Number:

-

Polyester Mesh

-

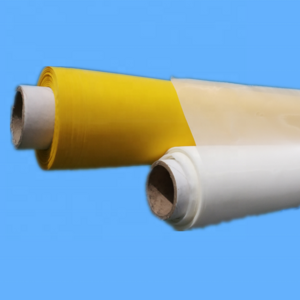

Color:

-

White

-

Length:

-

30m/50m/100m per roll or as request

-

Width:

-

165cm/65inch

-

Application:

-

Screen printing

-

weight:

-

3.5

-

Mesh Count:

-

47T

-

Tension:

-

Low

-

wave:

-

Plain

-

Usage:

-

Fencing Protect Mesh,Screen Prinitng,T-shirt Screen Prinitng

Quick Details

-

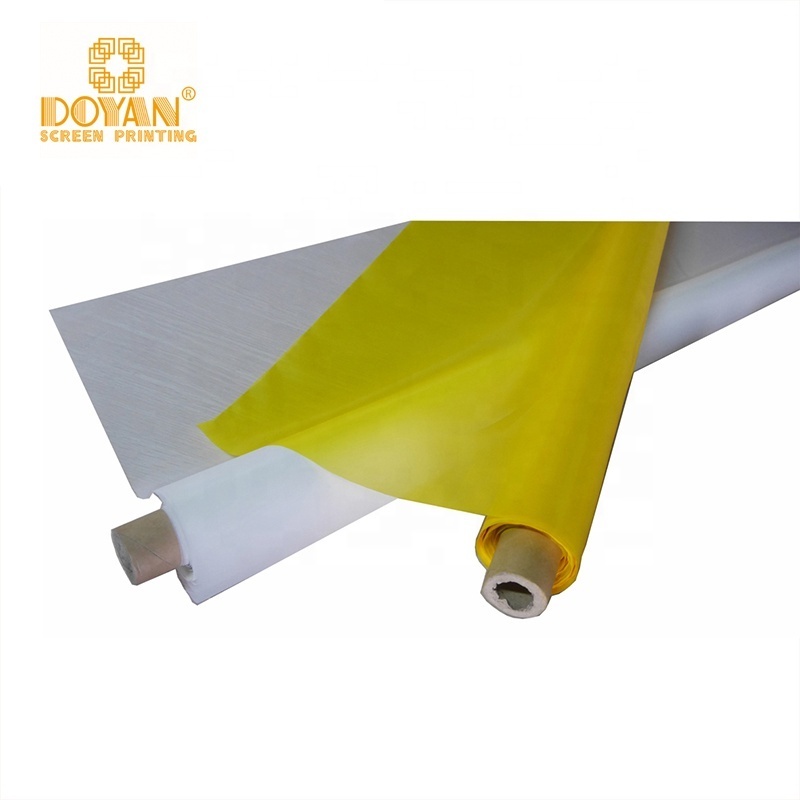

Material:

-

100% Polyester

-

Weave Type:

-

Plain

-

Elasticity:

-

Low

-

Printing:

-

Silk screen printing

-

Monofilament Style:

-

Yes

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DY screen printing mesh

-

Model Number:

-

Polyester Mesh

-

Color:

-

White

-

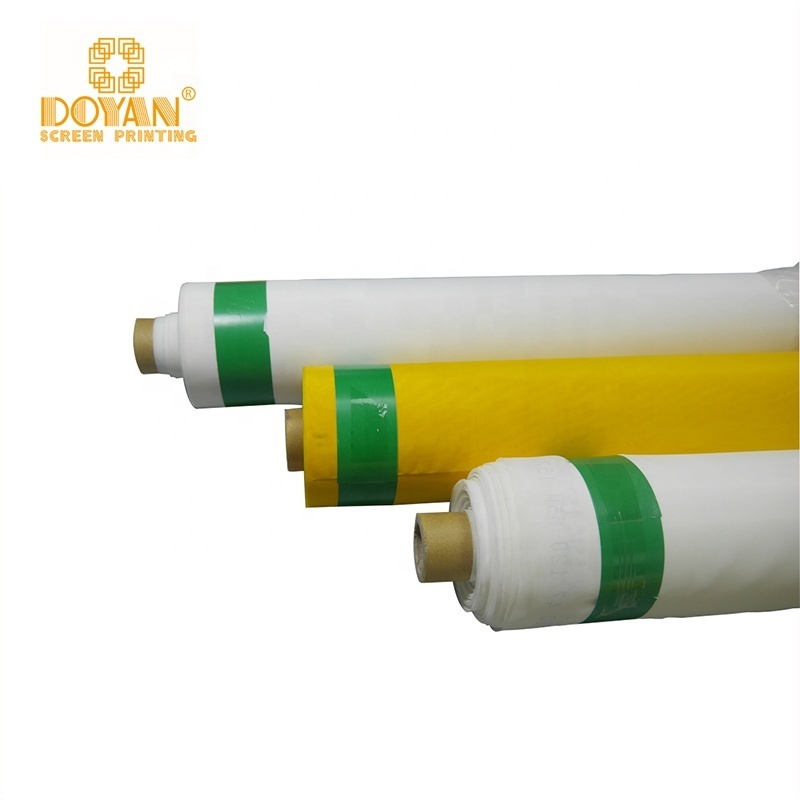

Length:

-

30m/50m/100m per roll or as request

-

Width:

-

165cm/65inch

-

Application:

-

Screen printing

-

weight:

-

3.5

-

Mesh Count:

-

47T

-

Tension:

-

Low

-

wave:

-

Plain

-

Usage:

-

Fencing Protect Mesh,Screen Prinitng,T-shirt Screen Prinitng

Hebei Doyan Screen Printing Equipment Co., Ltd. covers an area of 13,800 square meters. Since 2003, the company has introduced more than 200 projectile looms from Sulzer from Switzerland, and is also equipped with imported warping machines, imported setting machines, washing machines, cloth rolling machines and other equipment lines. With a strict and scientific quality management system, the company provides customers with competitive, precise and reliable products, solutions and services. Continue to create value for customers.

|

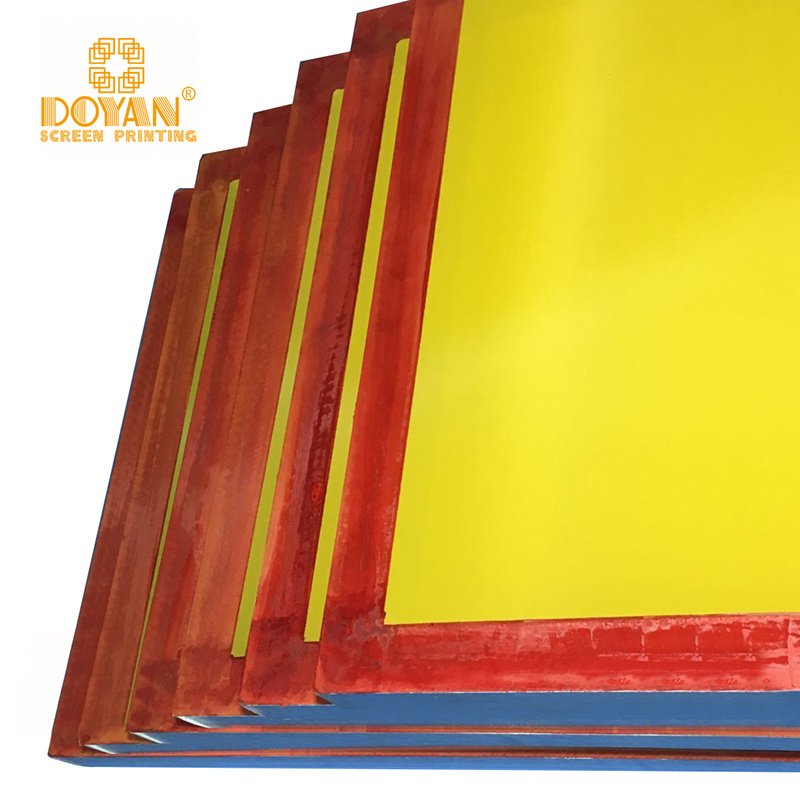

Screen printing mesh

|

|

|

|

Material:

|

100% polyester

|

|

|

Mesh count:

|

10T-165T(25-420mesh)

|

|

|

Mesh diameter:

|

31-250um

|

|

|

Width:

|

1.05M-3.6M

|

|

|

Weave Type:

|

plain

|

|

|

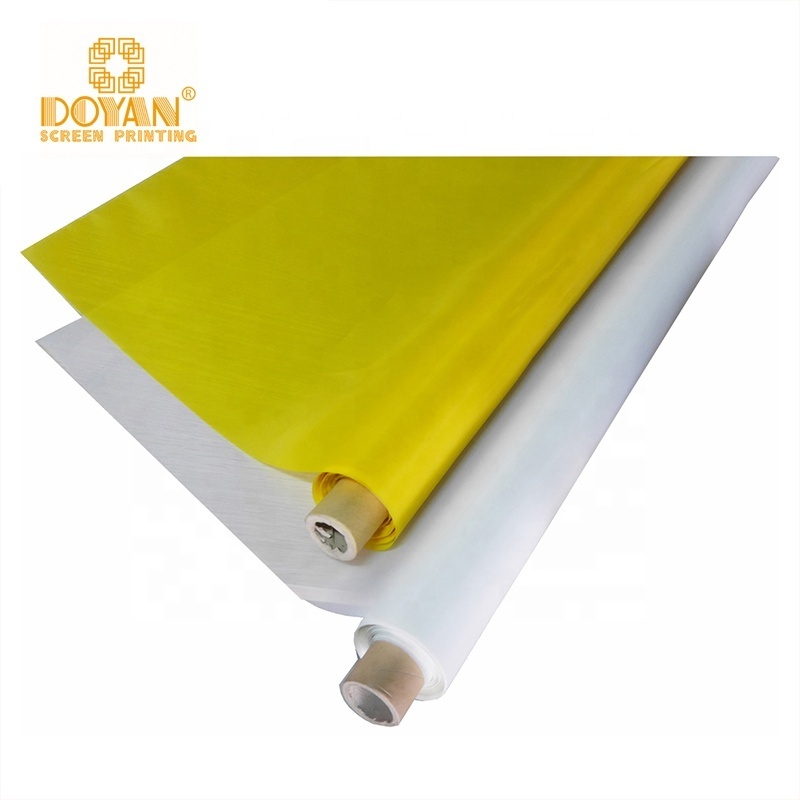

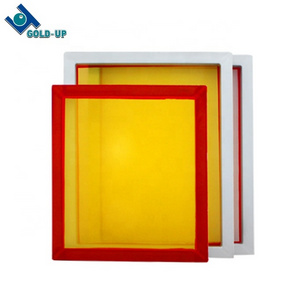

Mesh color:

|

White/yellow

|

|

|

Monofilament Style:

|

yes

|

|

|

Stretch tension:

|

0-40N

|

|

|

Application:

|

Screen printing

|

|

|

Packing:

|

50m/100m per roll

|

|

|

HS code

|

5911200010

|

|

KNOWING WHICH MESH COUNT TO USE.

24 and 38 mesh is used mainly for glitter inks that need a very open mesh for printing.

60 mesh is often used for printing smaller glitter and most shimmer inks.

86 mesh is also used for printing shimmer inks and for laying down thick layers of ink for high-density printing. It also works well for printing foil adhesive.

110 mesh makes printing white and other thick inks easy. It is ideal for spot color printing since it holds less detail than 156 mesh and lays down a thick layer of ink for maximum coverage.

125 mesh is one of the most commonly mesh sizes in screen printing. It works great for printing white ink and other colored inks that have a thicker viscosity.

156 mesh is great for general purpose textile printing with basic to semi-fine detail. It will hold a little finer detail than a 110 mesh while also working well with thinner inks.

200 mesh is great for printing more detailed prints that need a thinner layer of ink than a 156 mesh. It works very well with thinner inks and is a good middle-range mesh size.

230 mesh is great for high-end fine detail printing. A 230 mesh can hold halftones very well and also lets a little more ink through then a 305 mesh. The yellow color prevents light from reflecting through the threads of the mesh and keeps a sharper image when burning.

280 mesh screens are great for high-end fine detail printing. A 280 mesh can hold halftones very well and also lets a little more ink through then a 305 mesh.

305 mesh holds extremely high detail, letting through only a thin layer of ink. This allows for a very soft hand on the garment and is great for use in printing halftones and process prints. The yellow color prevents light from reflecting through the threads of the mesh and keeps a sharper image when burning.

Choose the Right Mesh Count

60 Mesh - A Course mesh count for use with Glitter Inks.

86/90 Mesh - Recommended for printing opaque white/light colors onto dark fabric to allow maximum opacity.

110 Mesh - Recommended for general textile work, printing light on dark, dark on light.

125/160 Mesh - Recommended for general textile work but with some finer detail/line work.

180/200 Mesh -Textiles; smooth and light fabric, Half-Tone, General.

230/250 Mesh - Textiles; extremely light material, Graphics, General.

305/355 Mesh - Process work

86/90 Mesh - Recommended for printing opaque white/light colors onto dark fabric to allow maximum opacity.

110 Mesh - Recommended for general textile work, printing light on dark, dark on light.

125/160 Mesh - Recommended for general textile work but with some finer detail/line work.

180/200 Mesh -Textiles; smooth and light fabric, Half-Tone, General.

230/250 Mesh - Textiles; extremely light material, Graphics, General.

305/355 Mesh - Process work

WHITE OR YELLOW MESH .

White mesh is the more economical of the two, and is primarily seen in lower mesh counts used for less-detailed designs. Higher count mesh is usually dyed yellow because the color yellow acts as a canceling factor for UV light and prevents refraction along the mesh strands when burning your screens. This allows for a more focused and precise exposure, keeping your screens as crisp as possible.

Hot Searches