- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

1800

-

Spindle Taper:

-

BT50/190 RPM 6000 direct

-

Dimension(L*W*H):

-

/

-

Weight (T):

-

22.5 T

-

Positioning Accuracy (mm):

-

0.021/0.019/0.014

-

Repeatability (X/Y/Z) (mm):

-

0.013/0.010/0.008

-

Range of Spindle Speed(r.p.m):

-

1 - 6000 r.p.m

-

Spindle Motor Power(kW):

-

18.5/22

-

Max. Table Load(kg):

-

5000 kg

-

Feed Speed(mm/min):

-

1 - 6000 mm/min

-

Rapid Feed Speed(m/min):

-

10/10/10

-

Tool Magazine Capacity:

-

Other

-

Place of Origin:

-

Yunnan, China

-

Brand Name:

-

WITH YOU PRECISION MACHINERY

-

Voltage:

-

380V

-

Core Components:

-

Servo Motor,Servo drive,Controller

-

After-sales Service Provided:

-

Online support/Video technical support/Free spare parts

-

After Warranty Service:

-

Spare parts

-

Local Service Location:

-

Malaysia/Singapore

Quick Details

-

Table Size (mm):

-

2500*1620

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

2500

-

Table Travel (Y) (mm):

-

1800

-

Spindle Taper:

-

BT50/190 RPM 6000 direct

-

Dimension(L*W*H):

-

/

-

Weight (T):

-

22.5 T

-

Positioning Accuracy (mm):

-

0.021/0.019/0.014

-

Repeatability (X/Y/Z) (mm):

-

0.013/0.010/0.008

-

Range of Spindle Speed(r.p.m):

-

1 - 6000 r.p.m

-

Spindle Motor Power(kW):

-

18.5/22

-

Max. Table Load(kg):

-

5000 kg

-

Feed Speed(mm/min):

-

1 - 6000 mm/min

-

Rapid Feed Speed(m/min):

-

10/10/10

-

Tool Magazine Capacity:

-

Other

-

Place of Origin:

-

Yunnan, China

-

Brand Name:

-

WITH YOU PRECISION MACHINERY

-

Voltage:

-

380V

-

Core Components:

-

Servo Motor,Servo drive,Controller

-

After-sales Service Provided:

-

Online support/Video technical support/Free spare parts

-

After Warranty Service:

-

Spare parts

-

Local Service Location:

-

Malaysia/Singapore

Products Description

|

Project

|

|

Unit

|

GMC1825

|

GMC1830

|

|

|

Workbench

|

length x station

|

mm

|

2500x1620

|

3000x1620

|

|

|

|

weight capacity

|

Kg

|

5000

|

6000

|

|

|

|

Number of T-slots x width x center distance

|

mm

|

9-22x180

|

|

|

|

Spindle

|

Specification

|

|

BT50/190

|

|

|

|

|

Rotating speed

|

Rpm

|

6000

|

|

|

|

Main Motor

|

rated power

|

Kw

|

18.5/22

|

|

|

|

Journey

|

X/Y/Z axis travel

|

mm

|

2500/1800/800

|

3000/1800/800

|

|

|

|

Spindle nose to table distance

|

Mm

|

280 〜1080

|

|

|

|

Shape

|

Total Weight

|

kg

|

22500

|

23500

|

|

|

Positioning Accuracy

|

|

mm

|

0.021/0.019/0.014

|

0.023/0.019/0.014

|

|

|

Repeatability

|

|

mm

|

0.013/0.013/0.010

|

0.016/0.013/0.010

|

|

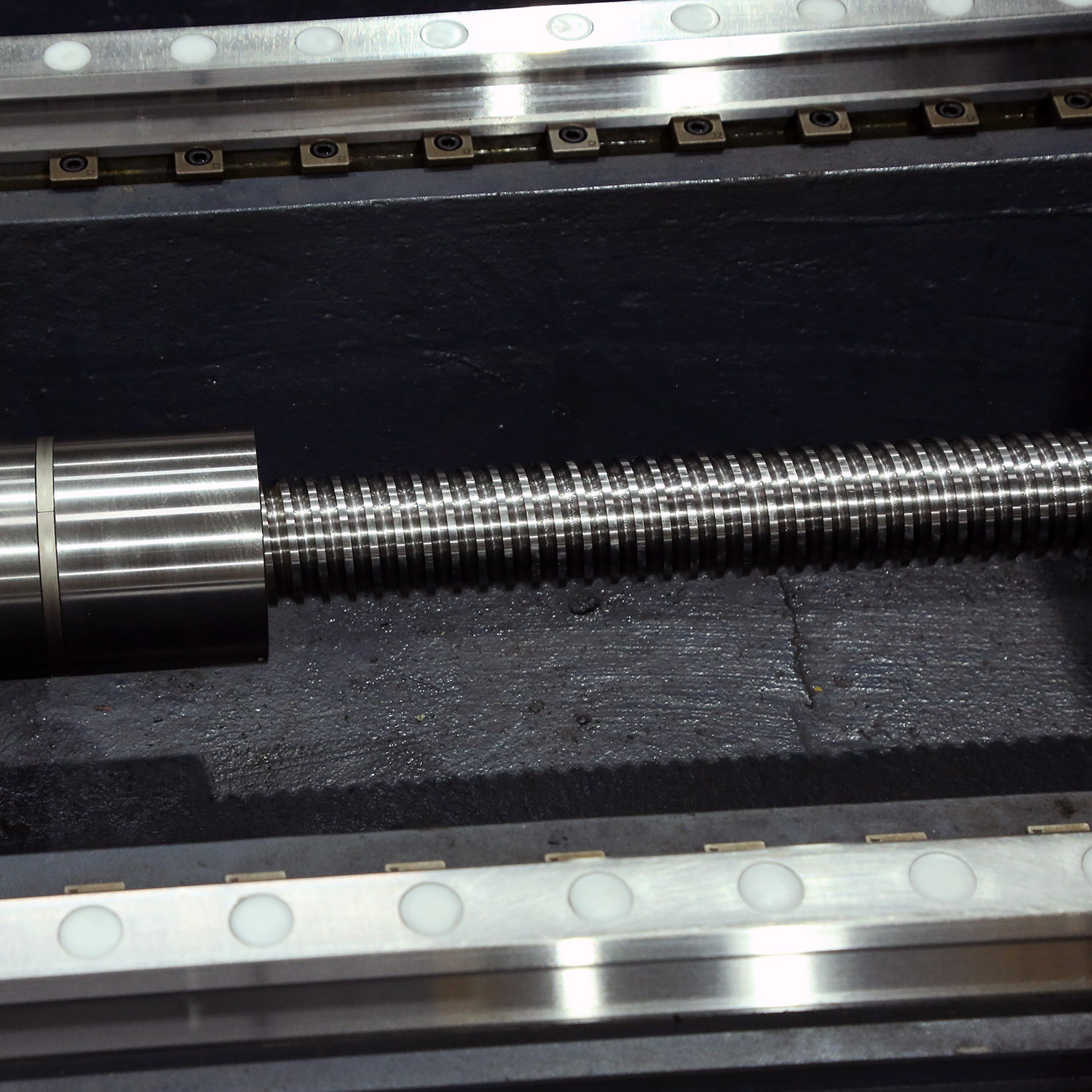

Spindle box structure

●The box adopts an integral structure

●The main shaft adopts Taiwan Gaoming as the director

The main motor is installed at the front end of the box by a bracket, and the main shaft and the main motor are connected by a synchronous belt

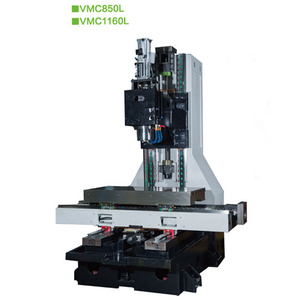

Beam frame structure

●The beam frame adopts a high-rigidity door-type structure, which has sufficient/dynamic rigidity and good precision retention.

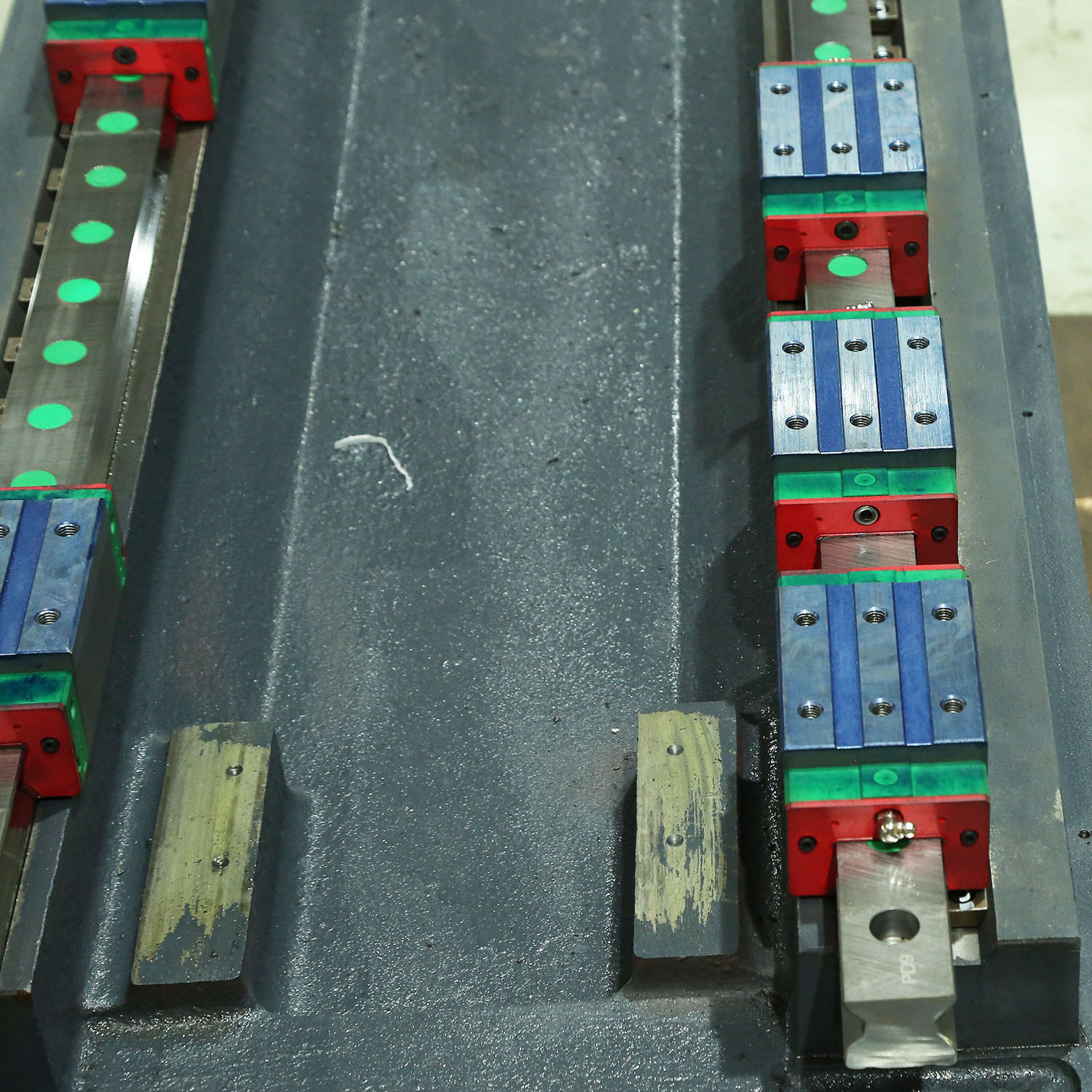

Slider structure

●The sliding seat adopts an integral structure, and the rigidity is greatly improved; it can withstand the axial and radial cutting force and vibration force, making the cutting faster and more effective.

Workbench structure

●Resin sand casting, high strength, 100% load-bearing on the base support when the table moves, and the load-bearing capacity is greatly improved.

base structure

The base and beam frame installation base are integrally cast, with good rigidity;

●The structure of double automatic chip conveyor is reserved, which belongs to the modular design, and the manual and automatic chip removal can be freely selected;

Ball bar rounding test

Tool Changing detection

Level indicator

Laser accuracy test

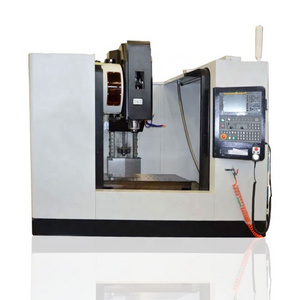

This series of gantry machining centers is equipped with a high-rigidity high-torque spindle and a high-dynamic response drive system, which is convenient and flexible to operate, safe and reliable, and can be widely used in aviation, aerospace, rail transit, automobile, mold and other mechanical processing fields. It can perform multi-process processing such as milling, boring, drilling, rigid tapping, reaming, and countersinking.

GMC1112/15/18 series machine tools adopt integrated gantry frame layout structure, GMC22 series machine tools adopt split gantry frame structure, and the machine tool has good rigidity. The inner cavity of the casting is a honeycomb-type composite arrangement structure. After aging and secondary tempering treatment. The machine tool is equipped with an automatic balancing system, with good stability and fast response.

More Products

Hot Searches