Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BEIERMAN

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

6m*1.6m*2.5m

-

Power (kW):

-

110

-

Weight:

-

8000 KG

-

Raw material:

-

PVC/PVC-C/ABS POWDER

-

Motor power:

-

110Kw

-

Motor brand:

-

SIEMENS "BEIDE"

-

Feeding motor power:

-

15Kw

-

Feedin method:

-

double screw

-

Vacuum pump motor power:

-

1.5Kw

-

Inverter brand:

-

ABB

-

Capacity:

-

800Kg/h

-

Marketing Type:

-

New Product 2022

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

92/188

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BEIERMAN

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

6m*1.6m*2.5m

-

Power (kW):

-

110

-

Weight:

-

8000 KG

-

Raw material:

-

PVC/PVC-C/ABS POWDER

-

Motor power:

-

110Kw

-

Motor brand:

-

SIEMENS "BEIDE"

-

Feeding motor power:

-

15Kw

-

Feedin method:

-

double screw

-

Vacuum pump motor power:

-

1.5Kw

-

Inverter brand:

-

ABB

-

Capacity:

-

800Kg/h

-

Marketing Type:

-

New Product 2022

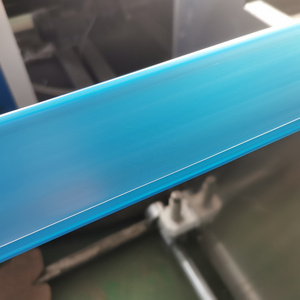

Conical twin screw extruder ,

specially designed for the PVC powder extruding,

it can be equipped in

PVC pipe production line,

PVC profile production line,

WPC profiles production line,

also used for PVC hot die face granulating line.

PVC Conical twin screw extruder ' screw structure also can re-designed according to customer's detail raw material and the purposes.

we can produce many of different models extruders,

such as SJSZ45/90; 45/100; 48; 50/105(also can be said 51/105); 55/120(or 55/110); 65/132; 80/156; 92/188;110/220.

or also can according to customer's required design.

there are horizontal type gearbox, integral vertical type gearbox.

Here I take one of our

SJSZ92/188 Conical twin screw extruder

with normal horizontal gearbox for example:

|

No.

|

Detail parameter

|

|

1

|

Driving motor: 110KW,AC motor,380V,3phase,50Hz,or up to customer's country

|

|

2

|

Motor and gear box direct connect by couplings

|

|

3

|

Screw diameter: 92/188mm*2(conical screw)

|

|

4

|

Screw,barrel material 38CrMoAIA(JIS SACM645)

|

|

5

|

Surface treatment Nitriding and polishing treatment,thickness:0.5-0.7mm

|

|

6

|

Screw,barrel surface hardness:H740-940

|

|

7

|

Barrel heater:6pcs, total heating power: 72KW

|

|

8

|

barrel cooling air blowers,0.55KW*5pcs=2.75KW in total

|

|

9

|

barrel venting system vacuum pump:2.2KW,vacuum meter:1pc,storage barrel:1pc.

|

|

10

|

Dimension(L*W*H, mm):6200*1600*2500. Weight:7800kg.

|

Screw and barrel

Screw and barrel

Gearbox

Feeder

inverter

Driving motor

- Skilled workers for machines producing

- Experience engineers all with passports ready for customers services

- Good Prices get from square quantity major parts purchase with lower cost

- Full line running test for customer checking before delivery

- world famous brands major parts:

|

Motor:

|

with SIEMENS, Dazhong,WEG

|

|

Inverter

|

with ABB/Delta/LS

|

|

Contactors

|

with SIEMENS/Schneider

|

|

Temperature

|

with OMRON/RKC/FUJI

|

- Zhangjiagang Beierman Machinery Co.,Ltd. is a modern factory, which engaged in the plastic extrusion machines and recycling machines' researching,manufacturing and sales.

-Our professional research teams,sales teams,rich experience and processing equipment will offer customers high quality machines and perfect after sales services.

-High quality,Quick services,Mutually beneficial principle will be our promise to customers around the world.

Ribbon mixer, low speed mixer~~~for PVC powder;

Hopper dryer mixer~~~for plastic granules;

Color mixer~~~for plastic granules.

2, PC/PMMA/ABS LED light diffuser,bottom tube making line.

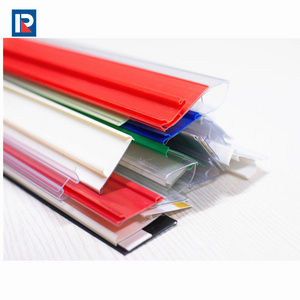

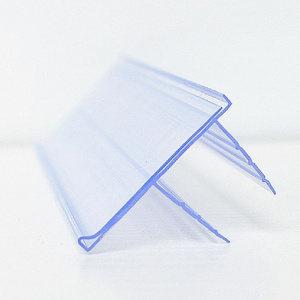

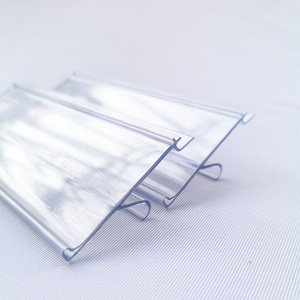

3,PVC Supermarket Price tag profile production line; Soft seal production line; Rigid rod production line.

4,Single screw extruder;

5,Conical twin screw extruder;

6, 2layer; 3 layer;4 layer PPR pipe co-extrusion line; PPR, PE, HDPE, PE-RT pipe production line;

7, Corrugated pipe extrusion line (Single wall corrugated; Double wall corrugated);

8, 3 layer PVC pipe co-extrusion line; PVC pipe production line;

9, PVC 2 cavity pipe production line;

10, PVC 4 cavity pipe production line;

11,Pipe belling machine;

12, PVC rain gutter profile line; Trunking/panel profile line;WPC profile production line; and 2 layer PVC profile co-extrusion

line;

13, Granulating line-water ring granulating,or string granulating (PP PE );

14, Granulating line-hot die face granulating (PVC).