- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

2500 r.p.m

-

Spindle Bore(mm):

-

310

-

Width of bed (mm):

-

310 mm

-

Spindle Motor Power(kW):

-

18.5

-

Travel (X Axis)(mm):

-

380 mm

-

Travel (Z Axis)(mm):

-

560 mm

-

Place of Origin:

-

Liaoning, China

-

Dimension(L*W*H):

-

1810*3580*3135

-

Brand Name:

-

DRC MACHINERY

-

Model Number:

-

VT600M

-

Voltage:

-

380V

-

Weight (KG):

-

6500

-

Marketing Type:

-

Hot Product 2024

-

Spindle nose:

-

A2-8

-

Rapid Traverse X/Z:

-

20/20

-

Main Drive Torque:

-

440

-

Turret type:

-

BMT65

-

Number BMT65 Tool Stations:

-

12

-

Number of Driven Tools:

-

12

-

Max. Installation Height above msl:

-

1000 m

-

Max. relative air humidity:

-

75 %

-

Air consumption:

-

15

-

Air Pressure:

-

6

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

600

-

Year:

-

2024

-

Max. Spindle Speed (r.p.m):

-

2500 r.p.m

-

Spindle Bore(mm):

-

310

-

Width of bed (mm):

-

310 mm

-

Spindle Motor Power(kW):

-

18.5

-

Travel (X Axis)(mm):

-

380 mm

-

Travel (Z Axis)(mm):

-

560 mm

-

Place of Origin:

-

Liaoning, China

-

Dimension(L*W*H):

-

1810*3580*3135

-

Brand Name:

-

DRC MACHINERY

-

Model Number:

-

VT600M

-

Voltage:

-

380V

-

Weight (KG):

-

6500

-

Marketing Type:

-

Hot Product 2024

-

Spindle nose:

-

A2-8

-

Rapid Traverse X/Z:

-

20/20

-

Main Drive Torque:

-

440

-

Turret type:

-

BMT65

-

Number BMT65 Tool Stations:

-

12

-

Number of Driven Tools:

-

12

-

Max. Installation Height above msl:

-

1000 m

-

Max. relative air humidity:

-

75 %

-

Air consumption:

-

15

-

Air Pressure:

-

6

Product Description

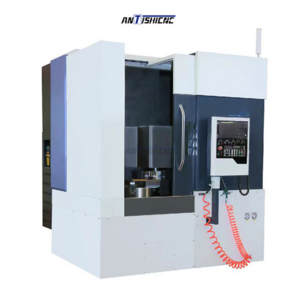

High Quality VT600M CNC Vertical Lathe Machine Metal Automatic Vertical Turning Milling Lathe Factory Manufacturer

The machine tool adopts HT300 high-strength cast iron bed, which has undergone two heat treatments and artificial aging (vibration) to eliminate the residual stress of the casting to the greatest extent. All assembly surfaces between motor bases and castings are precisely adjusted by manual scraping to ensure the overall accuracy of the machine tool.

In terms of design, the spindle column adopts a symmetrical box structure, which can provide reliable support for the turret during heavy cutting and reduce high-frequency vibration during milling. It is the structural foundation for high rigidity and high precision of the machine tool.

In order to adapt to large diameter and heavy load cutting, the machine tool is equipped with a 15\18.5Kw spindle motor as standard. The maximum turning speed can reach 2500rpm and the maximum torque can reach 440Nm. Taking into account the efficiency and responsiveness of linked milling, and the fact that most turn-milling applications use high-speed, large-depth-of-cut, and high-feed processes, the C-axis supports a maximum feed parameter of 36000°/min (100rpm/min) 440Nm. , to respond to the needs of high-speed milling to the greatest extent.

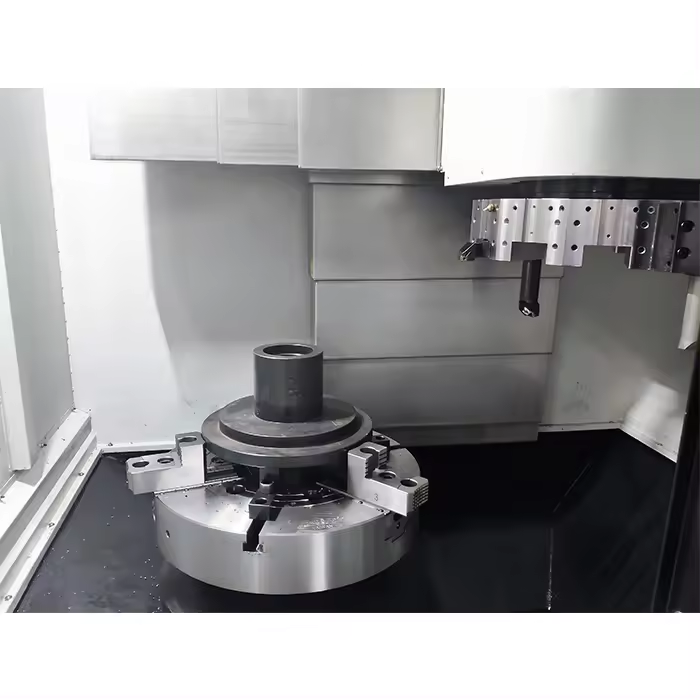

In terms of milling, it is equipped with a 100Nm 5.5kw milling motor with a maximum speed of 3000rpm. This adapts to the milling needs of different materials.

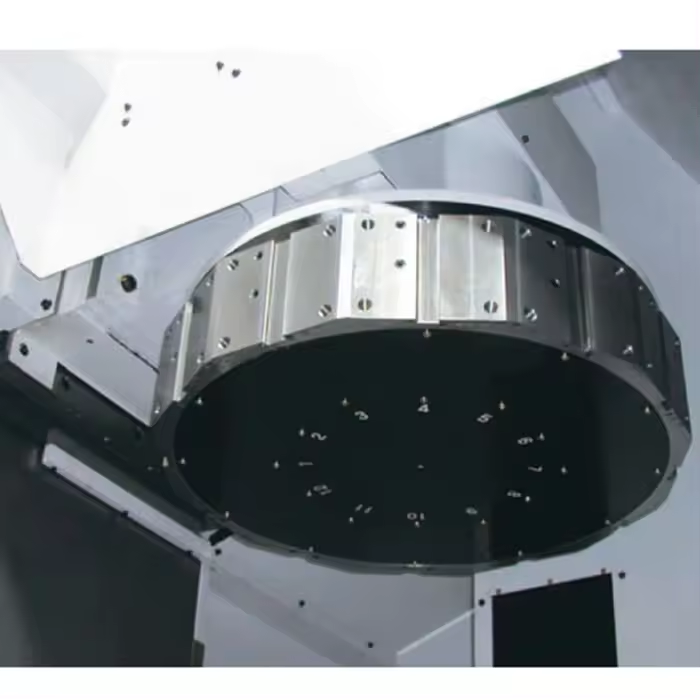

The 12-station turret equipped with BMT65 as standard has been verified by the design structure to ensure that there are no dead ends in the positive and negative tool installation angles. And the servo motor tool changing solution maximizes the execution efficiency of the turret and the repeated positioning accuracy of the tool, so that the tool changing time basically does not need to be considered when designing the process plan.

Considering green production and employee health, the machine tool adopts a fully enclosed sheet metal design and can be equipped with an optional oil mist collector to reduce the generation and spread of smoke, harmful particles, and aerosols.

Specification

|

Swing over Bed

|

Φ700

|

mm

|

|

Max. Turning Diameter

|

Φ600

|

mm

|

|

Max.table load

|

600

|

|

|

Recommended max. turning diameter

|

Φ390

|

mm

|

|

Clamping Chuck Diameter – main spindle

|

Φ310

|

mm

|

|

X travel

|

380

|

mm

|

|

Z travel

|

560

|

mm

|

|

Rapid Traverse X/Z

|

20/20

|

mm

|

|

Spindle nose

|

A2-8

|

|

|

Front Bearing Diameter

|

130

|

mm

|

|

Main Drive Power

|

15 / 18.5

|

kW

|

|

Main Drive Torque

|

440

|

Nm

|

|

Max. spindle Speed

|

2,500

|

rpm

|

|

Turret type

|

BMT65

|

|

|

Number BMT65 Tool Stations

|

12

|

|

|

Shank diameter

|

□25,Ø40

|

mm

|

|

Number of Driven Tools

|

12

|

|

|

Rated Power

|

5.5

|

KW

|

|

Max. Torque

|

100

|

Nm

|

|

Max Speed

|

3000

|

rpm

|

|

Coupling

|

BMT65

|

|

|

C-Axis Speed Range

|

100

|

rpm

|

|

C-Axis Torque

|

440

|

Nm

|

|

Accuracy of positioning in X/Z Axes

|

≤ 6 / 8

|

µm

|

|

Accuracy of repeatability in X/Z Axes

|

≤ 4 / 5

|

µm

|

|

Accuracy of positioning in C Axes

|

≤ 20

|

arcsec

|

|

Hydraulic Tank Capacity

|

35

|

l

|

|

Hydraulic Pressure, max.

|

55

|

bar

|

|

Coolant Equipment

|

|

|

|

Coolant tank capacity

|

180

|

l

|

|

Chip conveyor capacity

|

170

|

l

|

|

Pump Power

|

0,85

|

kW

|

|

Pump nominal flow rate at 5 bar

|

24

|

l/min.

|

|

Installed Power, max

|

50

|

kVA

|

|

Voltage

|

400

|

V

|

|

Frequency

|

50/60

|

Hz

|

|

Fusing (slow-blowing) according to VDE 0100

|

50

|

A

|

|

Allowed Voltage Fluctuation at 400 V

|

+ 10

|

%

|

|

Air Pressure

|

6

|

bar

|

|

Air consumption

|

15

|

m3/h

|

|

Room Temperature

|

+ 15 to + 35°C

|

|

|

Max. relative air humidity

|

75 %

|

|

|

Max. Installation Height above msl

|

1000 m

|

|

|

Net weight of the machine with chip conveyor

|

approx. 6500

|

kg

|

|

Machine with Chip Conveyor L x B x H

|

approx. 1810 x 3580 x 3135

|

mm

|

Hot Searches