1) fine and uniformity cells

2) low thermal conductivity

3) perfect flame resistance

4) good low temperature dimensional stability.

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

polyurethane foam

-

Place of Origin:

-

shandong

-

Brand Name:

-

DMJ

-

Model Number:

-

Spray505

-

Type:

-

PU foam liquid

-

Product Name:

-

water as blowing agent open cell spray foam

-

Application:

-

PU foam

-

Density:

-

35-50kg/m3

-

Blend polyols:

-

100

-

Isocyanate:

-

100-105

-

Storage Stability:

-

6 month

-

Storage Temperature:

-

10-25 ℃

-

Hydroxyl Value:

-

200-300mgKOH/g

-

Dynamic Viscosity:

-

100-200mpa.s

-

Special required foam:

-

customized for client

Quick Details

-

CAS No.:

-

9003-11-6

-

Other Names:

-

polyurethane foam

-

MF:

-

polyurethane foam

-

EINECS No.:

-

polyurethane foam

-

Place of Origin:

-

shandong

-

Brand Name:

-

DMJ

-

Model Number:

-

Spray505

-

Type:

-

PU foam liquid

-

Product Name:

-

water as blowing agent open cell spray foam

-

Application:

-

PU foam

-

Density:

-

35-50kg/m3

-

Blend polyols:

-

100

-

Isocyanate:

-

100-105

-

Storage Stability:

-

6 month

-

Storage Temperature:

-

10-25 ℃

-

Hydroxyl Value:

-

200-300mgKOH/g

-

Dynamic Viscosity:

-

100-200mpa.s

-

Special required foam:

-

customized for client

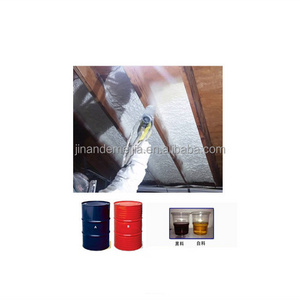

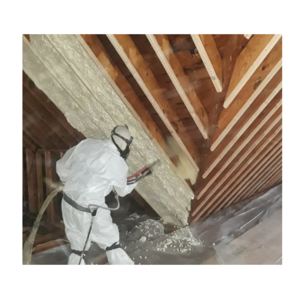

water as blowing agent open cell spray foam

The product is a mixture consisting of polyether polyols, silicone stabilizer, flame retardant and catalys. It is a light yellow liquid at room temperature. It has been developed to produce B1/B2 class fireproof outer wall spraying thermal insulation polyurethane foam in conjunction with polymeric ISO.

DMJ series polyol is a fully formulated polyol blend developed for spray application of polyurethane rigid foam. The component ratio of has been adjusted to make it suitable for polyurethane foam spraying machine using with a fixed volumetric component ratio of 1: 1.

|

Physical Properties

|

|

|

|

||

|

Appearance

Hydroxyl Value mgKOH/g Dynamic Viscosity (25 ℃) mpa.s Specific gravity (20 ℃ ) g/ml Storage Temperature ℃ Storage Stability month |

|

Pale yellow to brown viscous liquid

200-300 100-200 1.12-1.20 10-25 6 |

|

||

|

Recommended Ratio

|

|

|

|

||

|

blend polyols

Isocyanate |

|

100

100-105 |

|

||

|

Reactivity Characteristics

(The exact value varied depend on process condition)

|

|

close cell pu injection foam

|

|

||

|

Cream Time s

Gel Time s |

|

3-5

6-10 |

|

||

|

Foam Performances

|

|

|

|

||

|

Spray Density

Closed-cell Rate Initial Thermal Conductivity(15℃) Compressive Strength Adhesive Strength Elongation at break Dimentional Stability 24h -20℃ 24h 70℃ Water Absorption Oxygen Index |

|

>40kg/m3

≥90% ≤24mW/(m.K) ≥150kPa ≥120kPa ≥10%

≤1%

≤1.5%

≤3%

≥26 |

|

||

Typical properties of

water as blowing agent open cell spray foam

A and B

:

water as blowing agent open cell spray foam A and B

Component A: blend polyols

Component B: isocyanate

the foam also can be customized for client

water as blowing agent open cell spray foam A and B

package and shipping :

Component A is 220kg/iron drum;

Component B is 250kg/iron drum.

One set: 470 kg=220kg A+250kg B

One 20' container loads 40 sets/80 drums/18.8 tons

pu foam A

the spray machine price 900USD

pu foam B

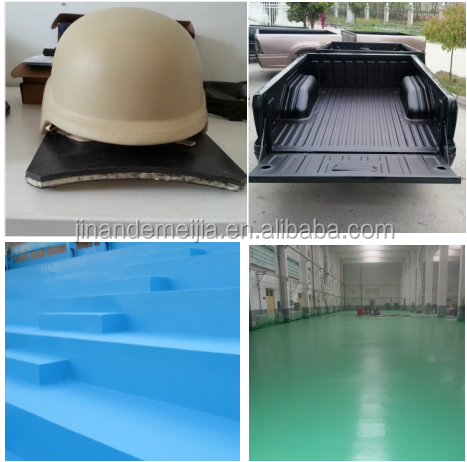

polyurethane insulation foam

two component polyurethane insulation foam

polyurethane foam inject material

pu foam polyurea spray machine

spray machine 900USD

Polyurea spray material cheap