- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

OEM

-

Model Number:

-

AlSn40 Bimetal bushings

-

Product name:

-

Bimetal steel bushing

-

Feature:

-

Wear-resisting

-

Bush types:

-

Sleeve Bushing

-

Color:

-

Customized Color

-

Finishing:

-

Bronze-plating

-

Standard:

-

INTERTEK

-

Application:

-

Automobile

-

species:

-

Compound Bearing

-

Packing:

-

Carton+Pallet

-

Size:

-

Customized

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Other

-

Type:

-

sleeve

-

Material:

-

AlSn40

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

OEM

-

Model Number:

-

AlSn40 Bimetal bushings

-

Product name:

-

Bimetal steel bushing

-

Feature:

-

Wear-resisting

-

Bush types:

-

Sleeve Bushing

-

Color:

-

Customized Color

-

Finishing:

-

Bronze-plating

-

Standard:

-

INTERTEK

-

Application:

-

Automobile

-

species:

-

Compound Bearing

-

Packing:

-

Carton+Pallet

-

Size:

-

Customized

Hot China CNC machining brass bush bronze bushing part

Bimetal Bearing – Factory Direct & Fast Shipping, These high-performance bimetal bushings bearing materials solve a host of problems that plague sliding parts.

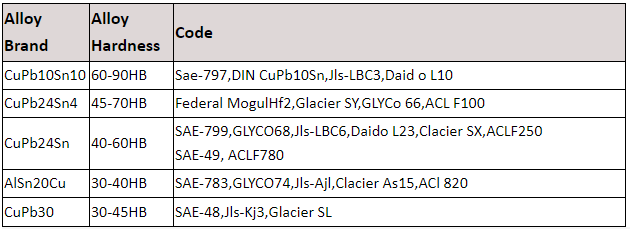

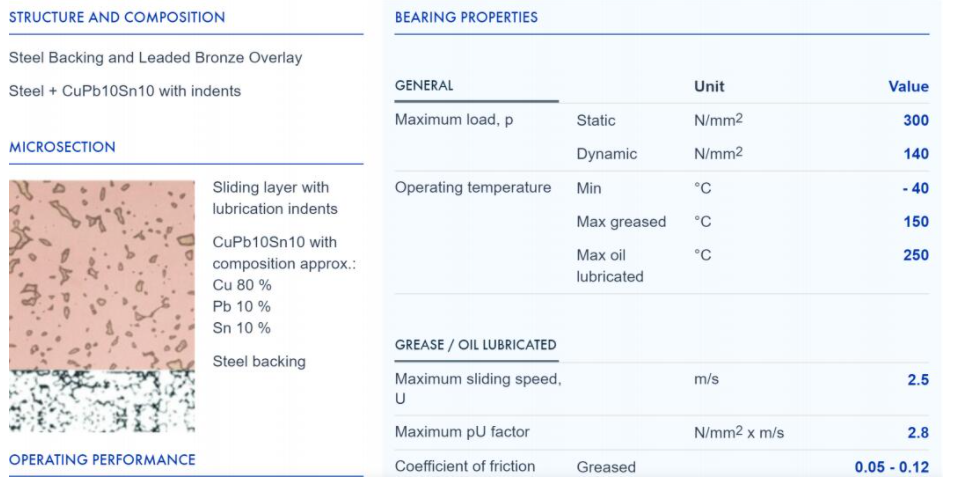

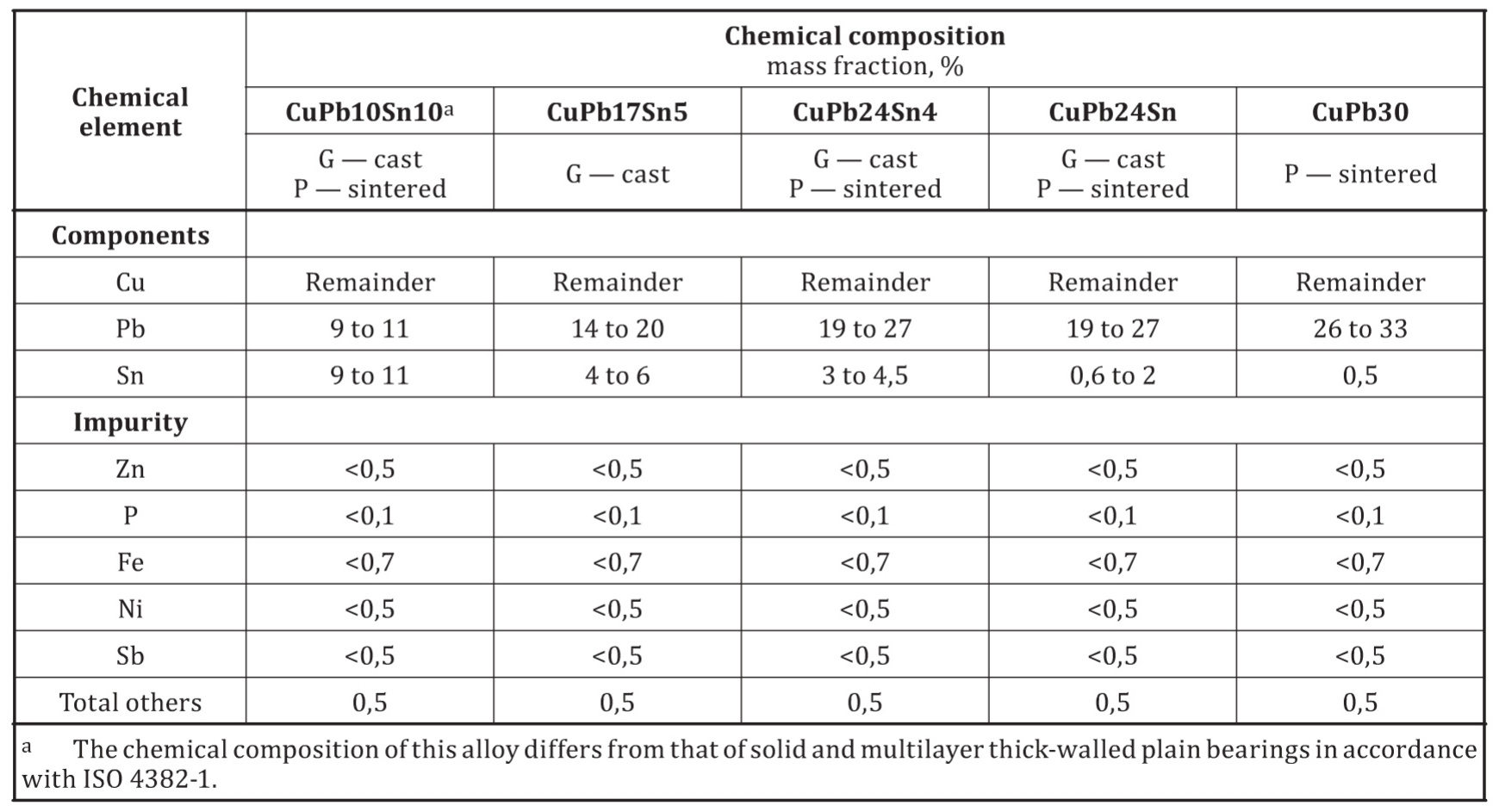

Bimetal Bearing Bushing -steel-backed bronze alloy composite bearings with high-quality low carbon steel as substrate, the surface of the sinter with low friction properties of copper alloy (CuPb10Sn10 CuPb6Sn6Zn3 CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as a wear-resisting layer of bearing, can need according to the operating conditions of copper alloy surface processing of various types of the oil tank, oil hole, hole, etc., in order to suit to cannot continue to go hard or go occasion. The material can get good bonding strength and best bearing capacity through secondary sintering and secondary extrusion.

Physical and Mechanical Performance

| Performance Index | Data | |

| Max Load P | 140N/mm? | |

| Linear Velocity V | Grease Lubrication | 2.5m/s |

| Oil Lubrication | 5m/s | |

| Max PV value | Grease Lubrication | 2.8N/mm? ·m/s |

| Oil Lubrication | 20N/mm? ·m/s | |

| Alloy Hardness | HB 60~90 | |

| Mating Axis | Hardness | ≥53HRC |

| Roughness | Ra=0.16~0.63 | |

| Working Temperature | Grease Lubrication | 150℃ |

| Oil Lubrication | 250℃ | |

| Friction Coefficient | 0.05~0.15 | |

| Heat-conducting Coefficient | 47W/(m·k) | |

| Heat-expansion Coefficient(Axial) | 18×10 -6 /K | |

Detailed parameters:

Related Products: