Water products are multifaceted, which could be natural spring water, purified water, carbonated water, flavored water... What process can be used to prevent the forming of bromate in side it? How to deploy mechanical filling valves to keep water clean and contaminant free? How to achieve the maximum benefit with speed, accuracy and light weight bottles? Tings machine, the expert in liquid filling machine, will always provide you with the best solution for your products.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TINGS

-

Dimension(L*W*H):

-

3400*1670*2350mm

-

Weight:

-

2000 KG

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Usage:

-

Water plant

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

After Warranty Service:

-

Video Support Online Support

-

Material:

-

Stainless Steel 304/316

-

Capacity:

-

2000-30000bph

-

Control:

-

PLC+ Touch Screen

-

Filling volume:

-

200ml-2000ml

-

Filling Liquid:

-

General Solution

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Plastic, Paper, Other

-

Filling Material:

-

Other, Water

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TINGS

-

Dimension(L*W*H):

-

3400*1670*2350mm

-

Weight:

-

2000 KG

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Usage:

-

Water plant

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

After Warranty Service:

-

Video Support Online Support

-

Material:

-

Stainless Steel 304/316

-

Capacity:

-

2000-30000bph

-

Control:

-

PLC+ Touch Screen

-

Filling volume:

-

200ml-2000ml

-

Filling Liquid:

-

General Solution

Product Description

Tings Water Filling Machine:

Application:

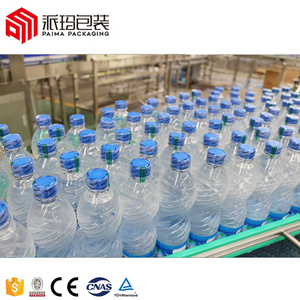

This machine is a washing-filling-capping integrated machine, which is mainly used for Non-carbonated drink, such as mineral water, pure water and so on. It is designed for shortening the contact time between drink material and outside, so as to improve the sanitation condition of the water product and increase the economy benefit.

Features:

It is designed with hanging type bottle conveying structure which makes the conveying of the bottles more convenient, faster and easier. Its main machine is equipped with advanced PLC control and key electric elements with international famous brand.

|

Model No.

|

TSGX8-8-3

|

|

Machine Type

|

Automatic

|

|

Bottle Type

|

PET round or square bottle

Volume 200 - 2000ml Bottle diameter 50-115mm Bottle height 160-320mm |

|

Capacity

|

2000 to 3000BPH

|

|

Washing Nozzle

|

8 pcs

|

|

Filling Nozzle

|

8 pcs

|

|

Capping Nozzle

|

3 pcs

|

|

Certificates

|

CE / SGS / ISO 9001

|

Advantage:

1. Safe contact between water and machine:

We use national standard stainless steel 304/316, Nickel content ≥8%.

2. High effeciency: 30 % reduction in changeover and maintenance downtime

3. Sustainable solution: servomotors reduce power consumption

4. Sanitary improved by liquid volume control and non-contact filling

5. Automatic bottle replacement improves run time

2. High effeciency: 30 % reduction in changeover and maintenance downtime

3. Sustainable solution: servomotors reduce power consumption

4. Sanitary improved by liquid volume control and non-contact filling

5. Automatic bottle replacement improves run time

Machine Details

Air Conveyor

- Air conveyor is fixed on the floor, with fan installed on the top.

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- Made of stainless steel 304/316.

- High quality carbon steel welded r ack and frame

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- Made of stainless steel 304/316.

- High quality carbon steel welded r ack and frame

Bottle Washing

- The washing table connect to the air conveyor directly, which make the working environment much cleaner.

- All 304/316 stainless steel nozzle, water inject design, high injecting accuracy, save water.

- 304/316 Stainless steel plier , high washing accuracy ensure no bottle falling during washing process.

- 304/316 stainless steel washing pump, durable and clean

- All 304/316 stainless steel nozzle, water inject design, high injecting accuracy, save water.

- 304/316 Stainless steel plier , high washing accuracy ensure no bottle falling during washing process.

- 304/316 stainless steel washing pump, durable and clean

Bottle Filling

- 304/316 Stainless steel high accuracy filling nozzle

- Filling volume adjustable, all bottles with same liquid volume after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no welding spot, easy to clean

- 304/316 stainless steel filling pump

- High accuracy inject nozzle, save water

- Filling volume adjustable, all bottles with same liquid volume after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no welding spot, easy to clean

- 304/316 stainless steel filling pump

- High accuracy inject nozzle, save water

Bottle Capping

- Electromagnetic capping heads, minimize the bottle falling during capping process

- All 304/316 stainless steel construction

- High capping accuracy, no cap missing

- Automatic stop when there are insufficient bottles

- Stable and reliable capping process, Defective rate ≤0.2%

- All 304/316 stainless steel construction

- High capping accuracy, no cap missing

- Automatic stop when there are insufficient bottles

- Stable and reliable capping process, Defective rate ≤0.2%

More models with different capacities:

The below parameters of capacity is just for reference. It depends on the bottle size.

|

No.

|

Model No.

|

Capacity

|

Washing Nozzle

|

Filling Nozzle

|

capping Nozzle

|

|

1

|

XGF8-8-3

|

2000-3000BPH

|

8

|

8

|

3

|

|

2

|

XGF14-12-5

|

3000-5000BPH

|

14

|

12

|

5

|

|

3

|

XGF18-18-6

|

6000-9000BPH

|

18

|

18

|

6

|

|

4

|

XGF24-24-8

|

10000-12000BPH

|

24

|

24

|

8

|

|

5

|

XGF32-32-10

|

12000-15000BPH

|

32

|

32

|

10

|

|

6

|

XGF40-40-10

|

15000-18000BPH

|

40

|

40

|

10

|

|

7

|

XGF50-50-12

|

18000-22000BPH

|

50

|

50

|

12

|

|

8

|

XGF50-50-15

|

22000-25000BPH

|

50

|

50

|

15

|

One-station service

We are factory. We can provide all necessary related equipments for bottled water filling line: Water treatment system, bottle blow molding machine, filling and capping machine, labeling machine, code injecting machine and shink warping machine for packing, etc.

Solution Support

We will provide you with the most suitable solution, accroding to your requirements.

Bottle Design

We can design the bottle according to size, style or sample you provide.

Layout of the equipments

Drawing for the equipment layout can be provided accroding to your plant layout.

Related Products

Packing&Shipping

Packed in wooden cases

Trade Fair

customers visiting

About Our Company

Hot Searches