- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LPE

-

Dimension(L*W*H):

-

2450*840*1650

-

Weight:

-

330 KG

-

Product name:

-

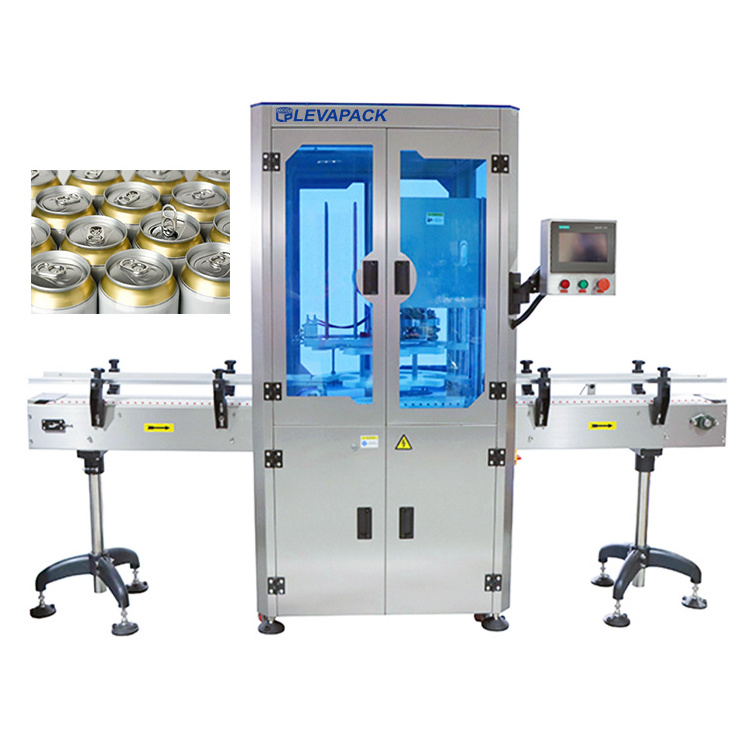

Automatic can sealing machine

-

Function:

-

For the sealing of round cans

-

Suitable for:

-

aluminum, tin, paper composite, PE cans

-

After-sales-Service:

-

Provided

-

Number of seaming rollers:

-

4

-

Number of seaming head:

-

1

-

Sealing speed:

-

30 cans/min

-

Sealing can diameter:

-

35-130mm

-

Sealing can height:

-

25-220mm

Quick Details

-

Packaging Type:

-

CANS

-

Packaging Material:

-

Plastic, Paper, Metal

-

Driven Type:

-

Electric

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LPE

-

Dimension(L*W*H):

-

2450*840*1650

-

Weight:

-

330 KG

-

Product name:

-

Automatic can sealing machine

-

Function:

-

For the sealing of round cans

-

Suitable for:

-

aluminum, tin, paper composite, PE cans

-

After-sales-Service:

-

Provided

-

Number of seaming rollers:

-

4

-

Number of seaming head:

-

1

-

Sealing speed:

-

30 cans/min

-

Sealing can diameter:

-

35-130mm

-

Sealing can height:

-

25-220mm

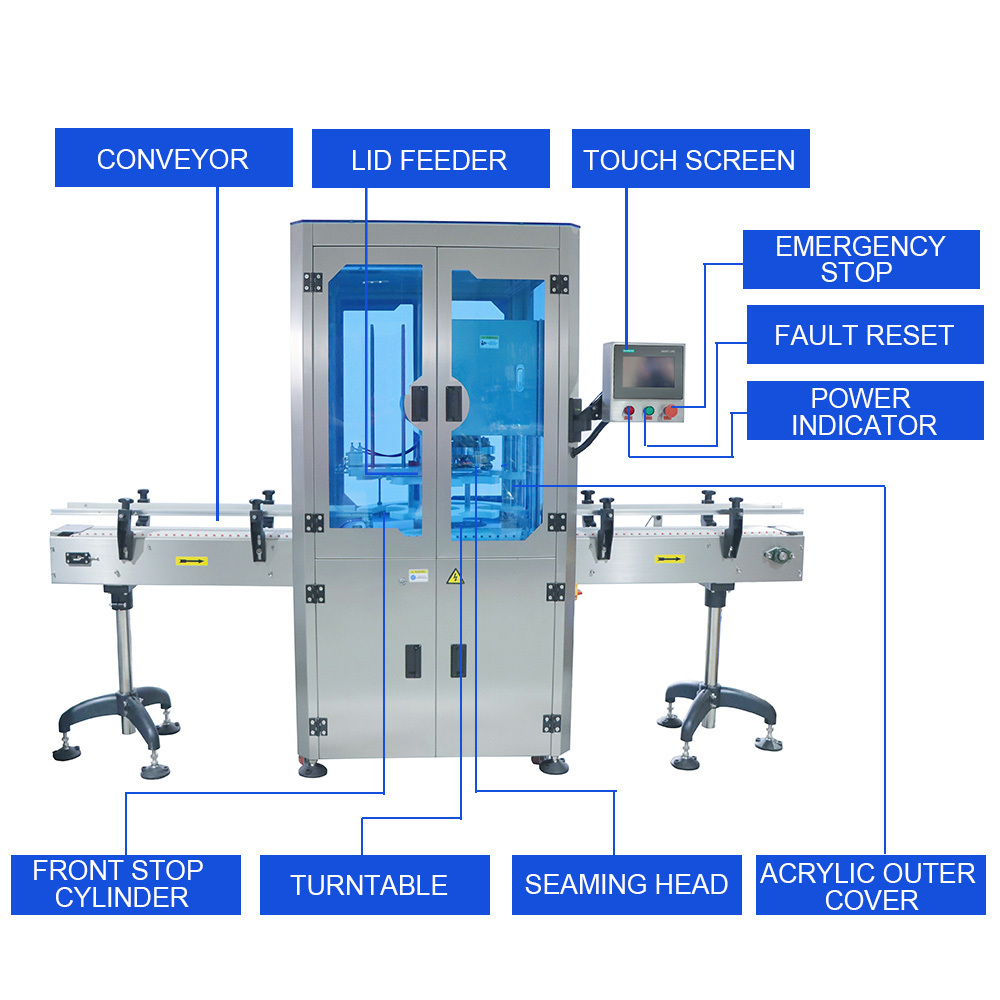

Product Overview

Automatic paper tube can seamer paper composite can sealing machine

This

machine suitable for the sealing of tin cans, aluminum cans, plastic cans and composite paper can.

It is an ideal machine for the sealing of beverage cans, such as beer cans, beverage pet cans

The working process: put the can on the coveyor- automatic feed the lid-automatic seal the lids- pick up the sealed cans on the

conveyor.

For more info, welcome to contact!

|

Features:

|

|

|

|

|

||||

|

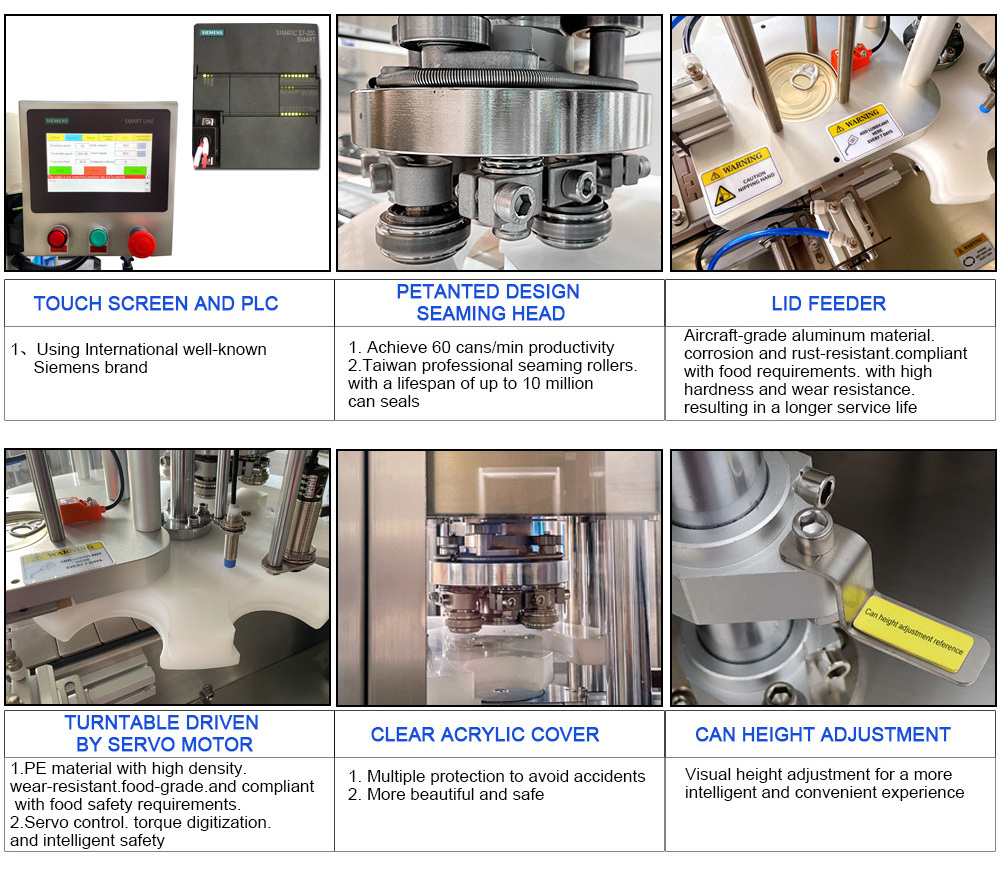

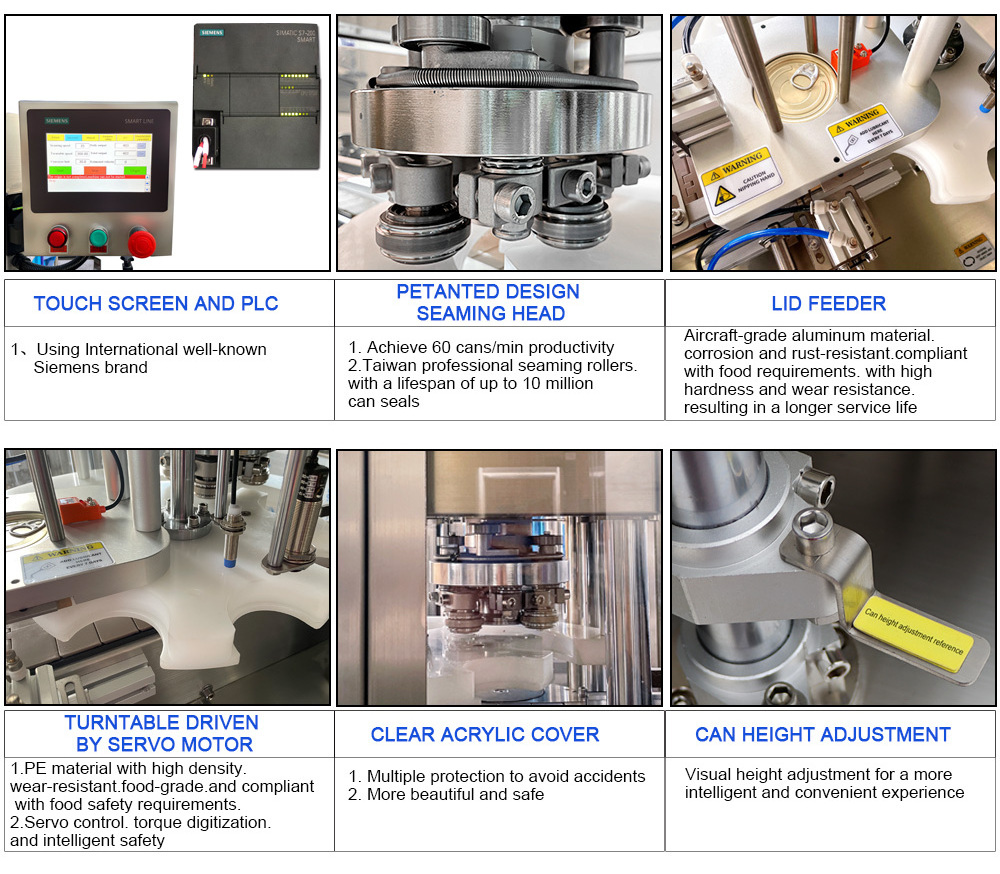

1.

|

Whole machine servo control makes the equipment run safer, more stable and smarter. Thetumtable only runs when there is a can, speed can be adjusted separately: when there is canstuck, the turntable will automatically stop. Ater one button reset, the error can be released andmachine restart to run: When there is a foreign object stuck in the furntable, it will automaticallystop running to prevent artificial Equipment damage and safety accidents caused by incorrecoperation of the equipment.

|

|

|

|

||||

|

2.

|

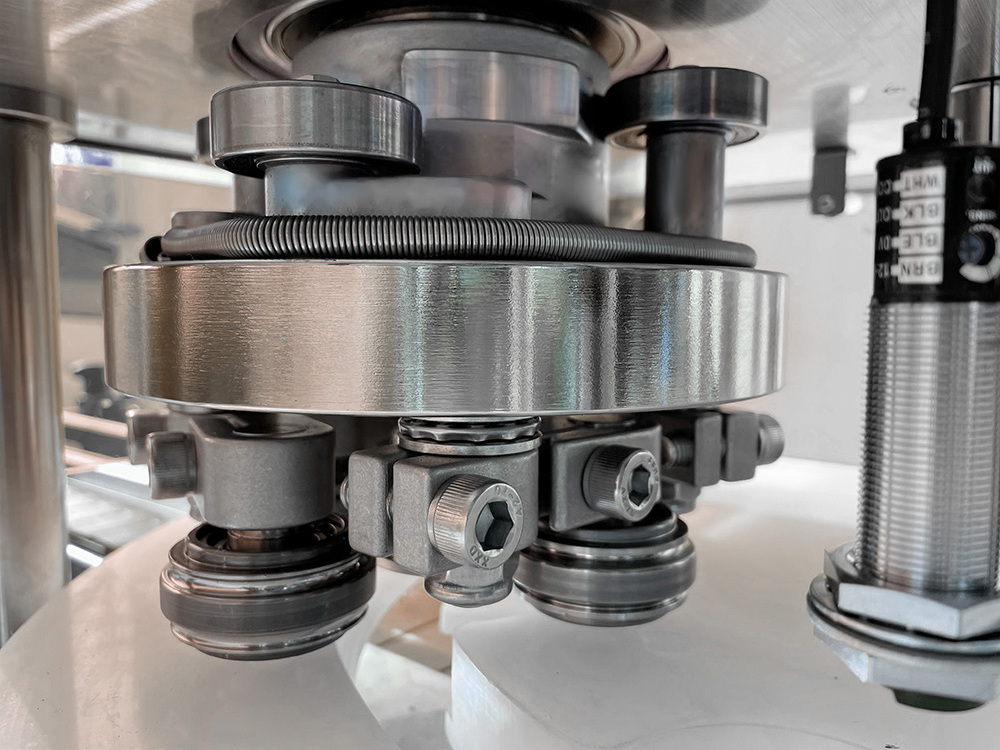

A tota of a seaming rollers are completed at the same time to ensure high sealing performance

|

|

|

|

||||

|

3.

|

The can body does not rotate during the sealing process, which is safer and is especially,suitable for fragile and liquld products.

|

|

|

|

||||

|

4.

|

The sealing speed is fixed at 33 cans per minute, production is automated, which improvesproduction efficiency and saves labor costs.

|

|

|

|

||||

|

5.

|

Applicable to tin cans, aluminum cans, plastic cans and composite paper can, it is the ideapackaging equipment for food, beverage,sauce industry etc.

|

|

|

|

||||

|

Main parameters:

|

|

|

|

|||

|

Number of sealing head

|

1

|

|

|

|||

|

Number of seaming rollers

|

4 (2 first operation, 2 second operation)

|

|

|

|||

|

Sealing speed

|

20-50 cans/ min ( adjustable)

|

|

|

|||

|

Sealing height

|

25-220mm

|

|

|

|||

|

Sealing can diameter

|

35-130mm

|

|

|

|||

|

Working temperature

|

0-45℃

|

|

|

|||

|

Working humidity

|

35-85%

|

|

|

|||

|

Working power supply

|

Single-phase AC220V S0/60Hz

|

|

|

|||

|

Total power

|

2100W

|

|

|

|||

|

Weight

|

330KG (about)

|

|

|

|||

|

Dimensions

|

L 1850 W 8404H 1650mm

|

|

|

|||

Can I visit your factory?

-Yes, we welcome to visit our 4000 ㎡ factory

How can I find the right packaging machine for my product?

-Please tell us the details of your product and packaging requirements.

1.What kind of product do you want to pack?

2.The size of the cans/bags you need to pack your product (length, width, height)

3.The weight of each package you require.

4.What is your production speed requirement for the machine?

-Please tell us the details of your product and packaging requirements.

1.What kind of product do you want to pack?

2.The size of the cans/bags you need to pack your product (length, width, height)

3.The weight of each package you require.

4.What is your production speed requirement for the machine?

Can your engineers provide installation services?

-

Of course. You will need to pay for our engineer's visa and return airfare, be responsible for the engineer's accommodation and pay $200 a day, or if you want to save money, we can support online video installation instruction.

If we have very special request for the production line,could you help me to do the design?

-

With over 18 years of experience, we are equipped with a team of experienced R&D and manufacturing engineers as well as a dedicated sales and after-sales service team to ensure you get consistent performance, great looks, smart equipment and a quality and satisfying service experience at a reasonable cost.

How can we make sure about the machine quality after packing the order?

-Before delivery, we will send you an acceptance video so that you can check the quality of the machine.You can also arrange for a quality check by yourself or by your contact person in China.

What about your guarantee of quality?

-The machine is 1 year warranty, all machine part can be replaced within 1year if broken(not including man made).

Can you explain me the whole transaction process?

-1.Negotiate product and transaction details by email

2.Signing of the sale and purchase contact after mutual agreement

3.Arrange 50% deposit and sample packaging to our factory

4.Factory arrange production

5.Testing & detecting the machine before shipping

6.Inspected by customer through online or site test

7.Arrange the balance payment before shipment

8.Packaged for shipment

Will you provides the delivery service?

-Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your

reference before delivery.

-Before delivery, we will send you an acceptance video so that you can check the quality of the machine.You can also arrange for a quality check by yourself or by your contact person in China.

What about your guarantee of quality?

-The machine is 1 year warranty, all machine part can be replaced within 1year if broken(not including man made).

Can you explain me the whole transaction process?

-1.Negotiate product and transaction details by email

2.Signing of the sale and purchase contact after mutual agreement

3.Arrange 50% deposit and sample packaging to our factory

4.Factory arrange production

5.Testing & detecting the machine before shipping

6.Inspected by customer through online or site test

7.Arrange the balance payment before shipment

8.Packaged for shipment

Will you provides the delivery service?

-Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your

reference before delivery.

Hot Searches