- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

5000 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mascot

-

Dimension(L*W*H):

-

3900*3600*3100mm

-

Power (kW):

-

22 kW

-

Marketing Type:

-

New Product 2023

-

Product name:

-

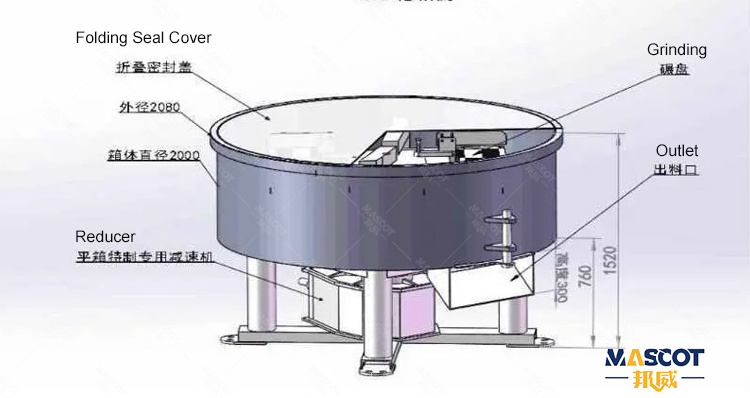

Roller Grinding Mixer Mill Coal Charcoal And Mineral Powder Mixer

-

Keywords:

-

wheel mill

-

Color:

-

Customer's Requirement

-

After-sales Service Provided:

-

Online Support

-

Feature:

-

Working Efficiency

-

Raw material:

-

Coal

-

Brand:

-

Famous

-

Applicable materials:

-

other

-

Certificate:

-

CE/ISO9001

Quick Details

-

Barrel Volume (L):

-

4800

-

Max. Loading Volume (L):

-

4800 L

-

Range of Spindle Speed(r.p.m):

-

30 - 44 r.p.m

-

Weight (KG):

-

5000 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mascot

-

Dimension(L*W*H):

-

3900*3600*3100mm

-

Power (kW):

-

22 kW

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Roller Grinding Mixer Mill Coal Charcoal And Mineral Powder Mixer

-

Keywords:

-

wheel mill

-

Color:

-

Customer's Requirement

-

After-sales Service Provided:

-

Online Support

-

Feature:

-

Working Efficiency

-

Raw material:

-

Coal

-

Brand:

-

Famous

-

Applicable materials:

-

other

-

Certificate:

-

CE/ISO9001

Double roller sand mixer,wheel grinding mill charcoal mixer,roll mixer coal powder blending tank mixing machine mixer wheel mill

Application and usable scope of Wheel roller mixer:

Wheel roller mixer, apply to mixing solid material and liquid material in casting workshop, widely applied in various kinds of forming production line. It is a kind of ideal mixing equipment that can be easily used in the chemical industry, light industry, building materials, and other industries mixing with powder materials.

Features of wheel grinding mixer

1. Mix and grind at the same time.

2. High production efficiency.

3. energy-saving.

4. Easy to install and maintain.

5. Good sealing property.

Technical Parameters

|

Item |

Diameter (m) |

Power (kw) |

Capacity (kg/h) |

|

M - 11 |

1.1 |

5.5 |

1-1.5 |

|

M - 12 |

1.2 |

4 |

850 |

|

M - 13 |

1.3 |

5.5 |

1.5-1.8 |

|

M - 15 |

1.5 |

7.5 |

1.7-2 |

|

M - 18 |

1.8 |

11 |

1.8-2 |

|

M - 20 |

2.0 |

17 |

2-3.5 |

|

M - 22 |

2.2 |

22 |

4 |

Wheel grinding mixer working principle

After the machine is at work, the wheels will run continuously in its pan, and the charcoal or coal powder is fed into the pan of a charcoal wheel roller mixer with water as well as a briquetting binder for grinding. Water can be fed into for mixing during the process to reach a certain moisture level for briquette making. Till the materials are ground and mixed well, the discharging hole can be opened to obtain all the materials within the charcoal wheel roller.

Flat mouth mixer small solid particle mixer maintenance instructions:

1. Check the machine parts regularly, 1-2 times a month. The inspection items are whether the worm, bearing, shaft seal, and other moving parts are running smoothly and whether they are worn. If any defects are found, they should be repaired in time for normal use.

2. Electrical control parts should be kept clean and sensitive, and any faults should be repaired in time.

3. After one use or shutdown, the remaining materials should be taken out of the mixer equipment, and the remaining powder in each part of the machine should be cleaned. If it is not used for a long time, the machine must be completely wiped clean and covered with a tarpaulin.

4. The stirring paddle of the mixer should be dismantled lightly, installed stably, and placed lightly when disassembling, so as to avoid deformation and damage.

Zhengzhou Mascot Environmental Technology Co., Ltd is a company that integrates science, industry, and trade. The company mainly sells mechanical equipment and accessories, briquette-making machines, shredder machines, granulating machines, and mineral processing equipment. Our company follows a human-oriented mentality, honest, pioneering entrepreneurial spirit with scientific and technological innovation. We always regard technology as the motive force, and the market as the orientation to make the products at the first-class level. In product sales, we pursue the refined service and keep improving from pre-sales consulting, and on-purchase service to after-sales service.

Mascot's comprehensive service system covers technical support, after-sales service support, and spare part support, which is one of the important reasons why we are appreciated by customers. Mascot always strives to provide customers with the most valuable purchasing experience.

FAQ

1. Are you a manufacturing or trading company?

We are a factory, established in 2010.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at the lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already built many mining projects in China & Overseas.