- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

780*700*1100mm

-

Weight:

-

105 kg

-

Product name:

-

corn cob crusher

-

Hammer number:

-

24

-

Speed:

-

4000rpm

-

Feed port:

-

280*220mm

-

Capacity:

-

400-1000kg/h

-

Raw material:

-

corn cob

-

Function:

-

for crushing corn cob

Quick Details

-

Max. Capacity:

-

10 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UD

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

780*700*1100mm

-

Weight:

-

105 kg

-

Product name:

-

corn cob crusher

-

Hammer number:

-

24

-

Speed:

-

4000rpm

-

Feed port:

-

280*220mm

-

Capacity:

-

400-1000kg/h

-

Raw material:

-

corn cob

-

Function:

-

for crushing corn cob

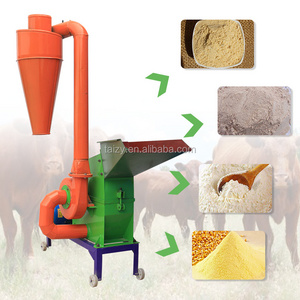

9FQ maize stalk crushing machine/corn cob hammer mill crusher/corn stalk shredder machine

screen

inside

Technical parameters for corn cob crushing machine

|

Model |

UD9FQ-420 |

|

Power |

11kw |

|

Hammer number |

24 |

|

Speed |

4000rpm |

|

weight |

105kg |

|

dimension |

780*700*1100mm |

|

Feed port |

280*220mm |

|

Capacity |

400-1000kg/h |

corn crusher, corn crushing machine, grass hammmer mill, grass grinder, branch crushing machine, straw crushing machine, nut shell crushing machine

Suitable for grinding corn, wheat, beans, grains, straw, vines, dry fresh potato, leaves the shell, such as food and feed, can also be shattered wood, branch, gypsum, aluminum powder, rare earth, chemical, pottery clay, coal and other minerals low hardness, and can crush a variety of traditional Chinese .

Working principle

When working, the material to be processed from the hopper into the crushing chamber, by the high-speed rotation of the working parts of the fight against and rupture, while changing the direction of movement of the material, due to high-speed rotation of the working parts of the destruction of the material layer deposition, In this process, the particles are repeatedly subjected to the impact of the working parts and the body and the collision between the particles, friction, which is gradually crushed to the geometric diameter is less than the diameter of the screen in the centrifugal force and airflow under the action of crushed material Through the sieve hole into the crushing chamber from the discharge port.